An integral circuit structure and its manufacture method

A technology of integrated circuits and manufacturing methods, applied in the direction of circuits, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of Schottky diode efficiency decline, increase design and assembly costs, affect the overall electrical properties of products, and achieve savings Design and assembly costs, improve integration, and improve electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

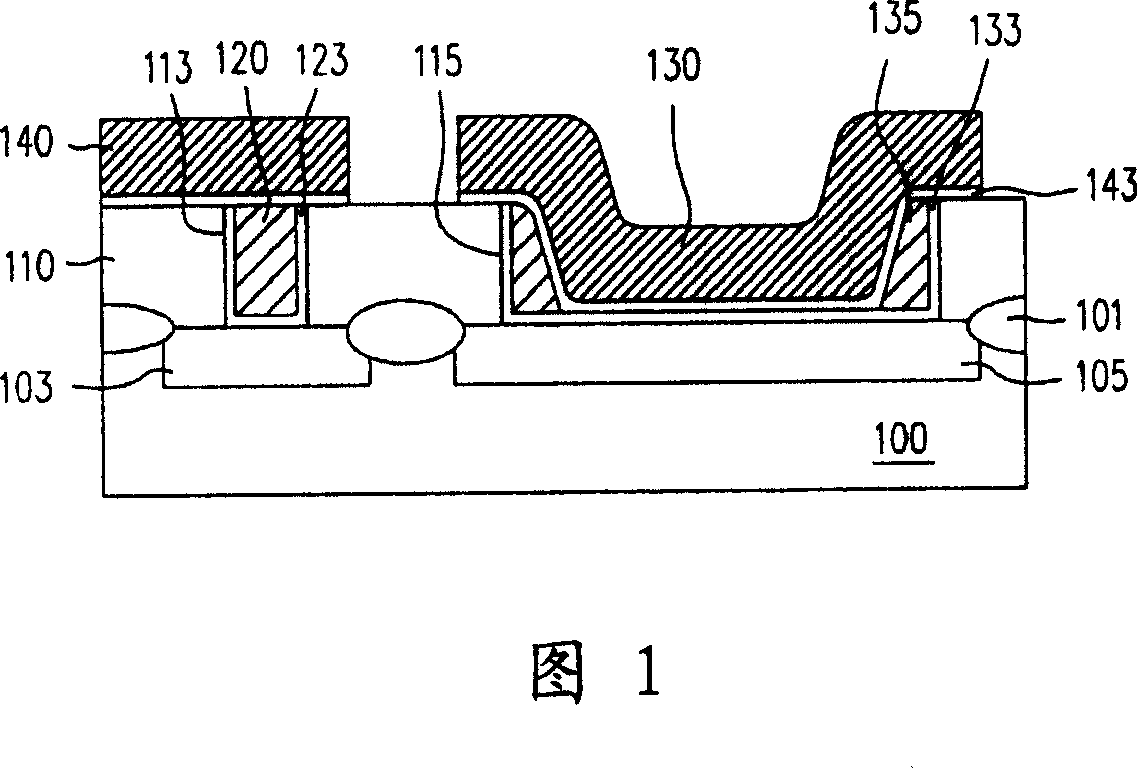

[0050] FIG. 1 is a schematic cross-sectional view of an integrated circuit structure according to an embodiment of the present invention. Referring to FIG. 1 , the integrated circuit structure includes a substrate 100 , a heavily doped region 103 , a lightly doped region 105 , a contact window 120 and a Schottky contact metal layer 130 . Wherein, the heavily doped region 103 and the lightly doped region 105 are disposed in the substrate 100 , which are separated by the isolation structure 101 , for example. The heavily doped region 103 is, for example, a doped region doped with P-type or N-type dopants. The heavily doped region 103 is, for example, the source and drain of a general logic element such as a MOS element or a memory element, and is heavily doped The impurity region 103 may be disposed in a well region (not shown). The lightly doped region 103 is different depending on the conductivity type of the substrate 100, for example, if the substrate 100 is a P-type substr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com