Pipe-chute sheet material for water treatment

A water treatment and sheet technology, applied in the direction of flocculation/sedimentation water/sewage treatment, settling tank, etc., can solve the problems of cost increase, inconvenience, excessive space, etc., achieve good economic and social benefits, and facilitate installation and maintenance , The effect of high connection firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

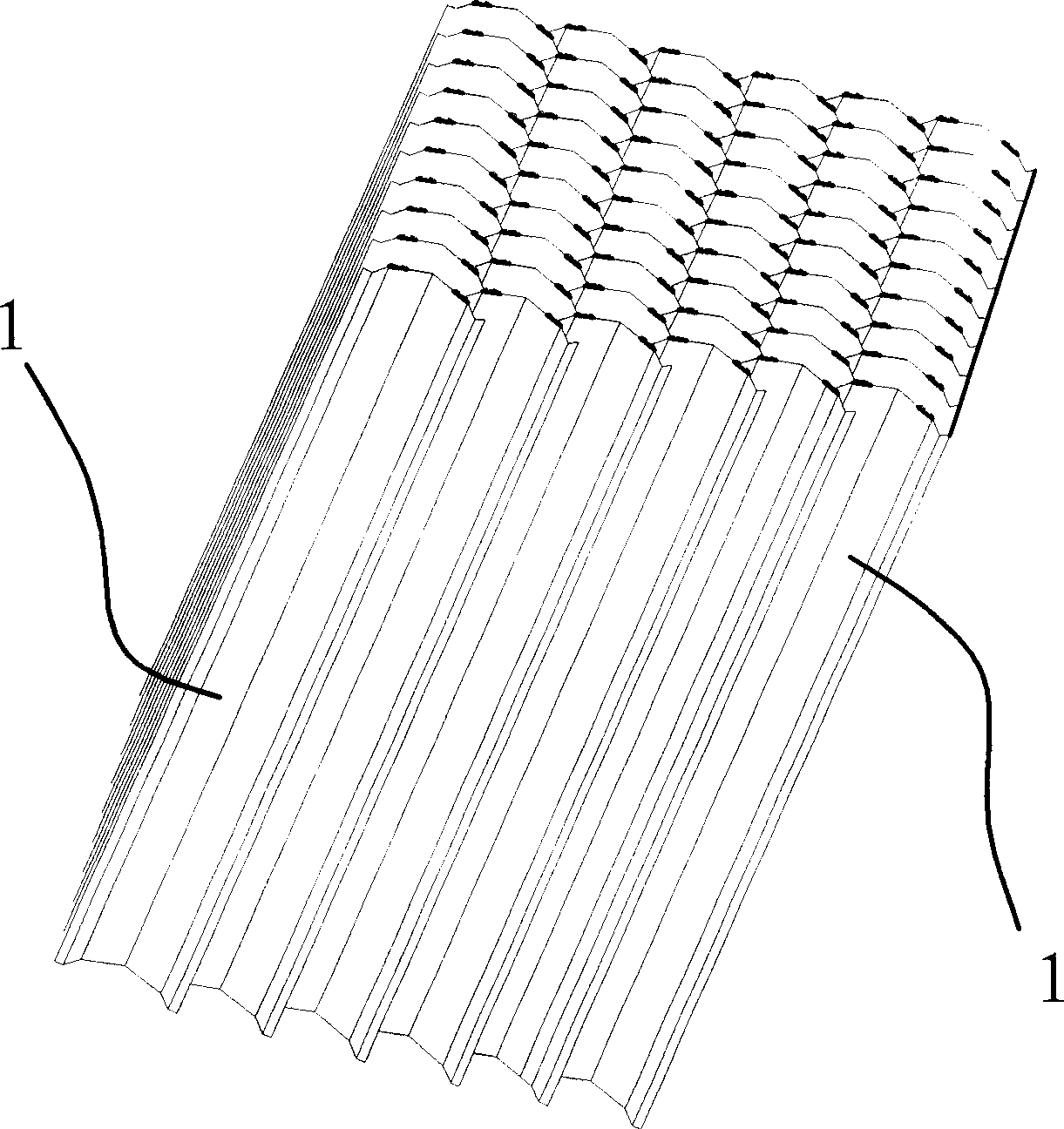

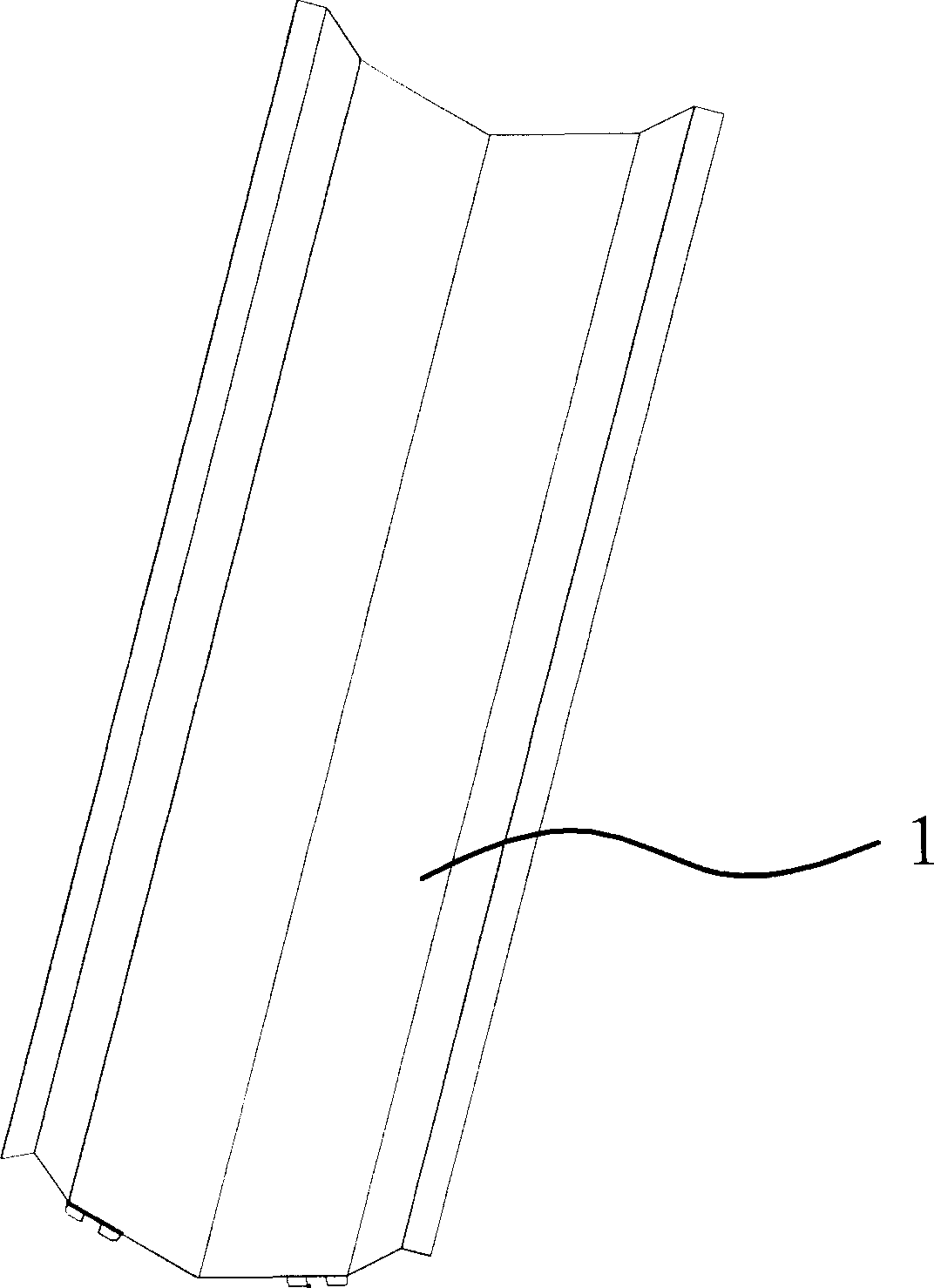

[0023] Such as figure 1 with figure 2 As shown, the inclined tube sheet 1 for water treatment is in the shape of a long strip, and the sheet 1 is recessed to one side to form the outer surface and the inner surface of the sheet 1 . Several sheets 1 are connected together to form an inclined tube, which is installed in the sedimentation tank, so as to achieve the purpose of improving sedimentation efficiency, reducing tank volume and improving water production efficiency.

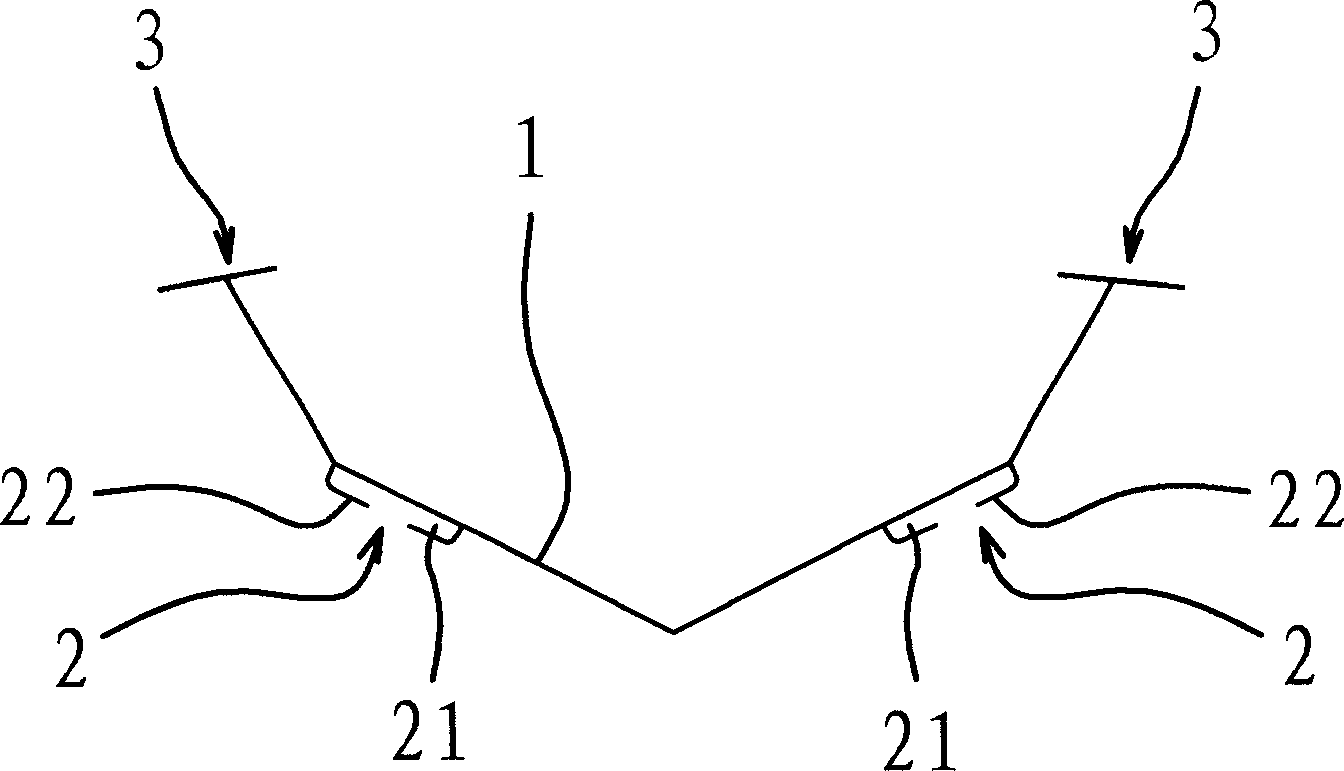

[0024] Such as image 3 As shown, the cross-section of sheet 1 is It is also feasible to set the cross-section of the sheet 1 as U-shaped or semicircular according to actual needs. The two corners of the outer surface of the sheet 1 are provided with two inserting parts-2 in parallel along the longitudinal direction, and the inserting parts-2 are arranged symmetrically. The two longitudinal edges of the sheet 1 are provided with two insertion parts 3 . The first insertion part 2 is a straight groove 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com