Harness cord device for prolonging service life of electronic jacquard machine

An electronic jacquard and thread technology, applied in the direction of jacquard, textile, textile and paper making, to achieve good economic and social benefits, save production time, and reduce labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

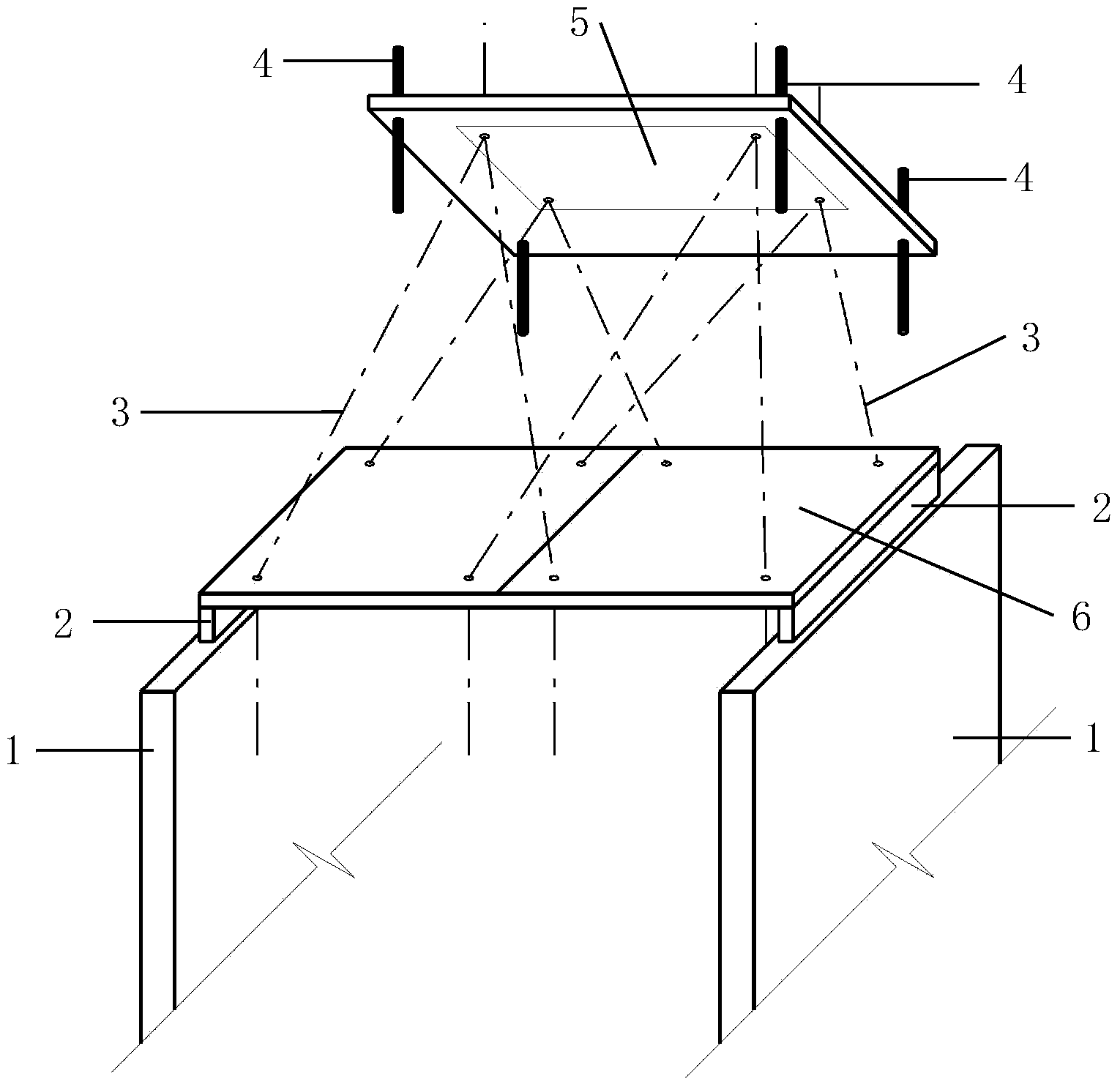

[0010] see figure 1 , the present invention comprises mesh board 6 and seabed board 5, and mesh board 6 is installed on the wallboard 1, and seabed board 5 is positioned at the top of mesh board 6, and between mesh board 6 and seabed board 5, there is through wire 3 to pass through, and through wire 3 The upper end is connected to the electronic jacquard machine, and the lower end of the wire 3 is connected to the steel heald spring. Its key technology is to be provided with spacer 2 at the contact position between the two edges of eye board 6 and wall board 1, and screw rod 4 is provided with bottom board 5 four corners to be used for fixing bottom board 5.

[0011] The height of the pad 2 is 10cm-15cm.

[0012] The length of the screw 4 is 18cm-25cm.

[0013] The screw rod and pads of the present invention can also be replaced by other components with a lifting effect, so as to achieve the lifting purpose of the eye plate and the seabed plate.

[0014] The present inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com