Design checking and construction method for infilled wall structural column formwork

A construction method and technology of structural columns, which are applied in formwork/formwork/work frames, building structures, walls, etc., can solve the problems of lack of formwork design models, calculation formulas and design methods for structural columns of filled walls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

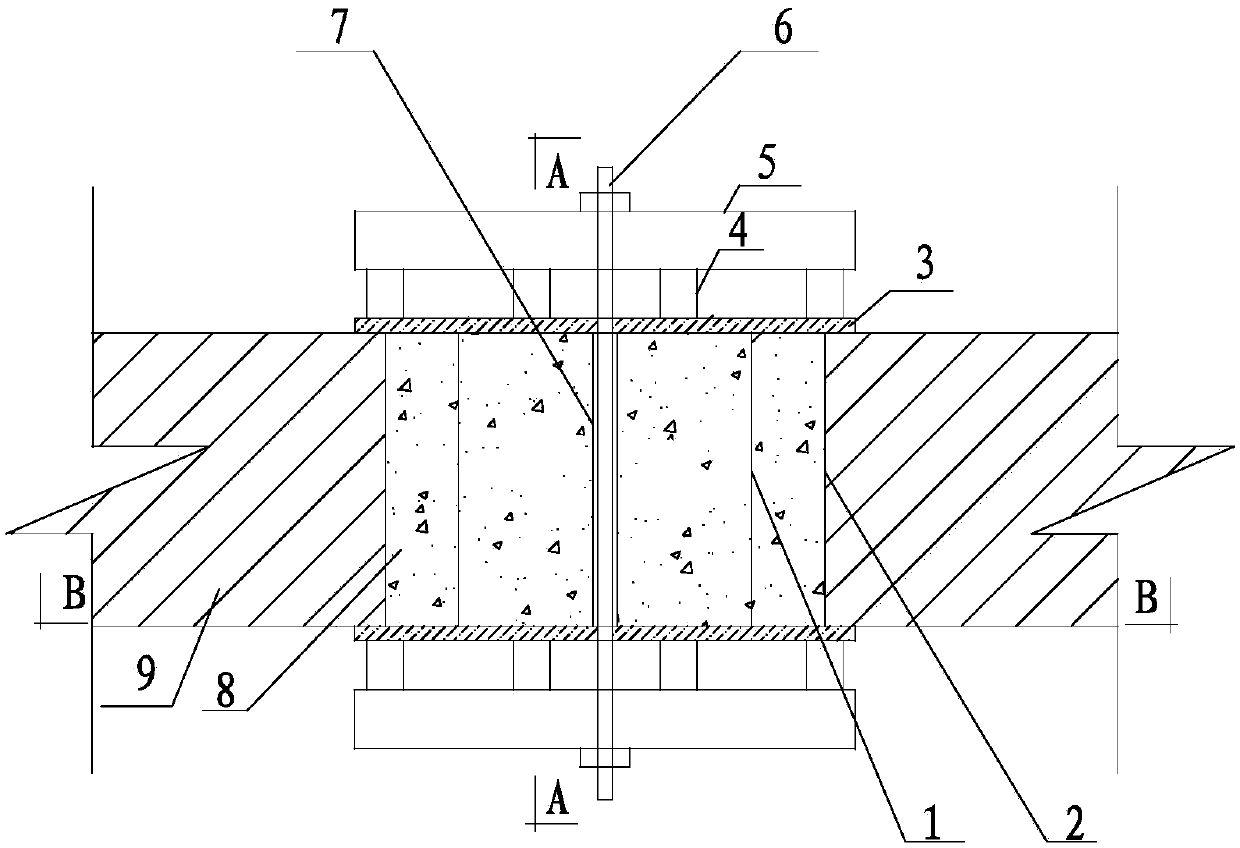

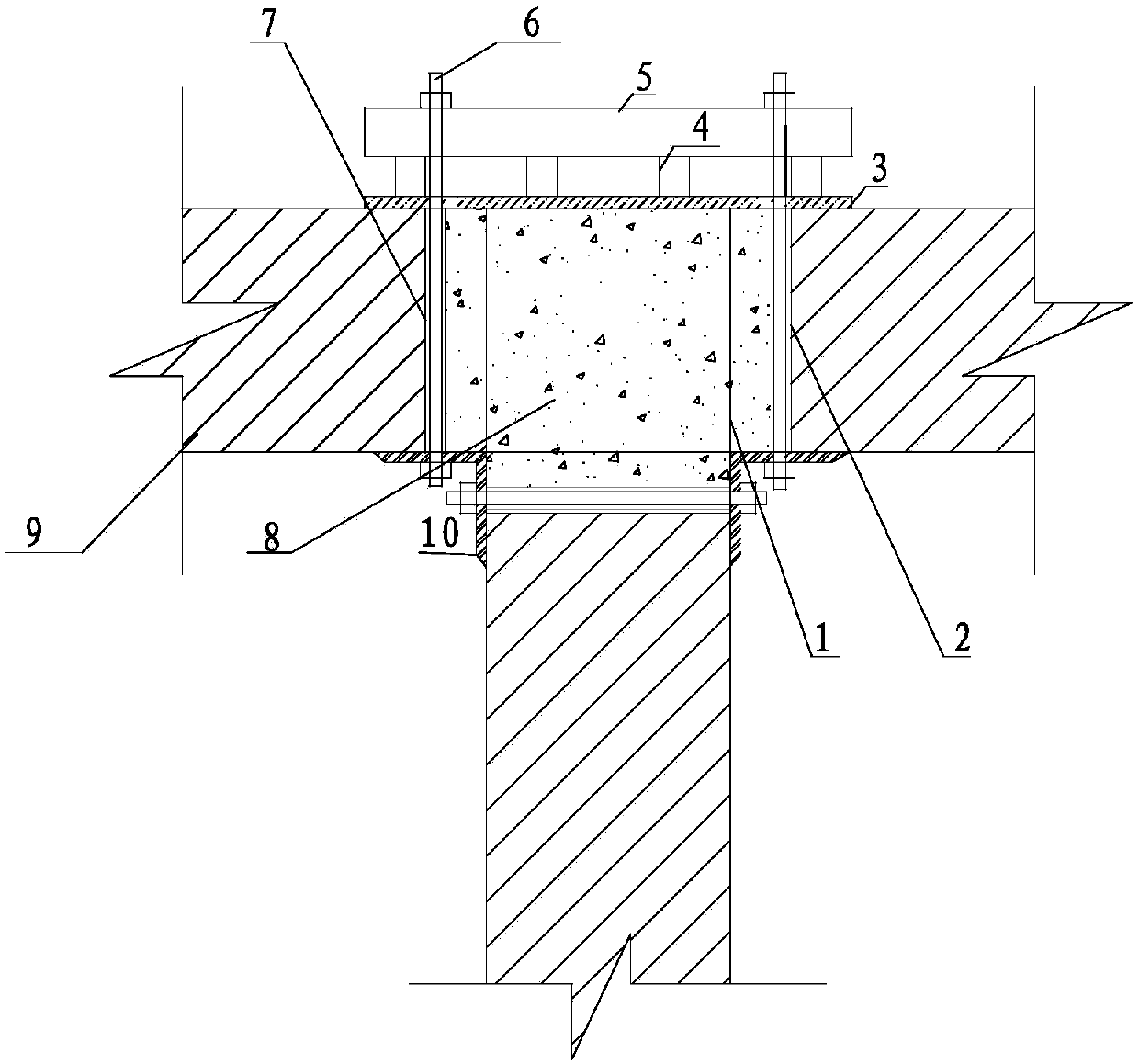

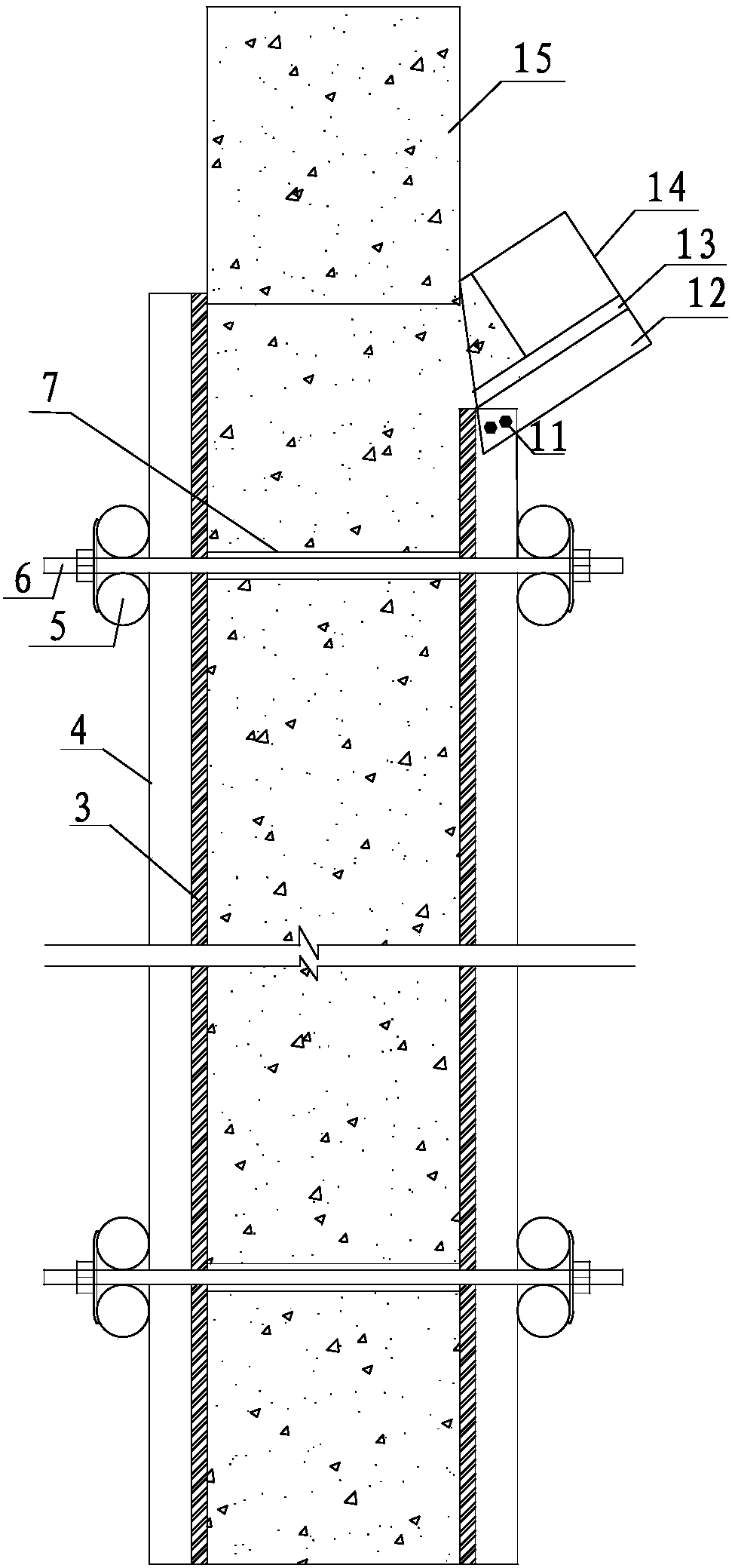

[0150] The present invention will be further described below in conjunction with accompanying drawing and filled wall 9 construction column formwork design cases:

[0151] Case overview: residential building with shear wall structure, floor height 2.9m, net height of structural columns 2.6m, straight and T-shaped infill walls 9 thick 240mm, net cross-sectional width of structural columns 240mm, both sides of structural columns protrude from the horse-toothed edge 2 Spacing 360mm, 15mm thick PVC panel 3, rectangular steel pipe □ 30×40×3 secondary flute 4, L100×5 equilateral inner corner formwork 10, inline and T-shaped filling walls 9 structural column formwork secondary flute 4 spacing (panel 3 span ) is 120㎜ and 130mm, φ48×3.0 double-steel pipe main corrugated 5 spacing 600mm, inline and T-shaped filling walls 9 construction column formwork tension bolts 6 are M14, M12 respectively, tension bolt casing 7 is PVC pipe of φ15 .

[0152] Such as Figure 1-5 Shown, filling wall ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com