Existing masonry structure transformation construction method

A construction method and technology of masonry structure, applied in the direction of building construction, building maintenance, construction, etc., can solve the problems of high construction cost, complex construction procedures, lack of scientific check calculation and analysis, etc. Convenience and improved visual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

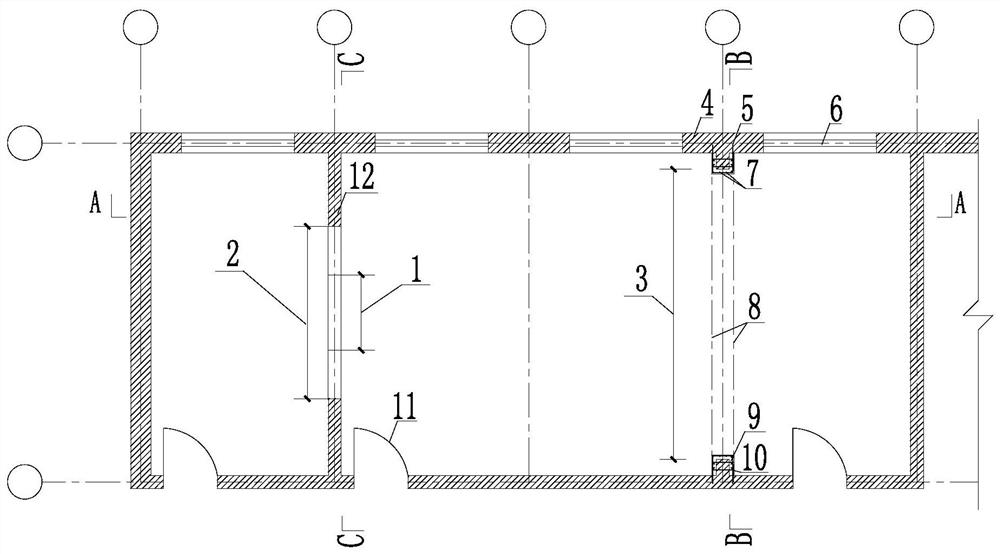

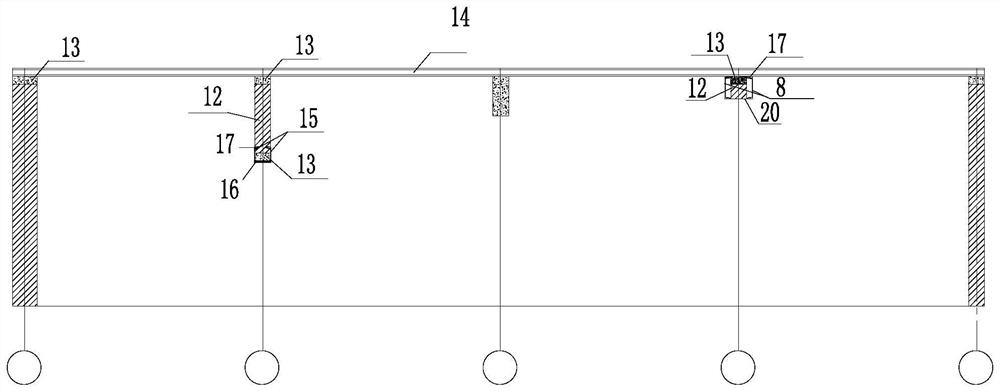

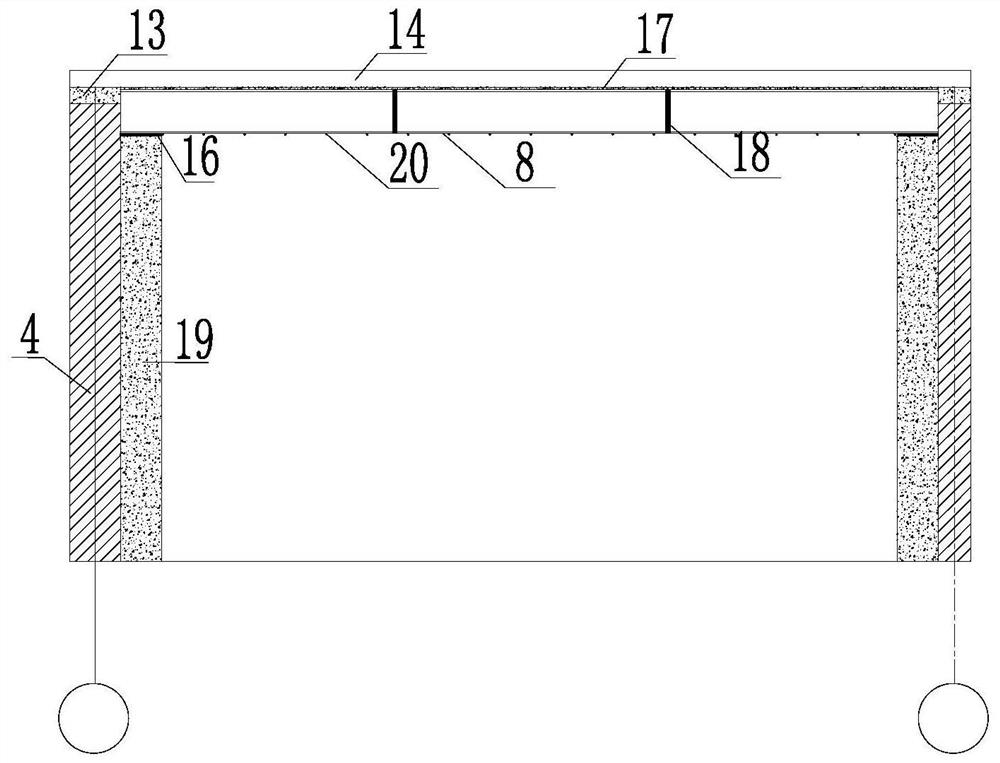

[0080] The present invention will be further described below in conjunction with accompanying drawing:

[0081] like Figure 1 to Figure 7 As shown, the existing masonry structure transformation construction method described in the present embodiment of the present invention takes the following steps:

[0082] 1. Double channel steel girder checking calculation:

[0083] 1.1. Determine the calculation model of the double channel steel girder:

[0084] 1) The extensional double channel steel beam 8 is supported by the extensional wall-attached supports 9 on both sides of the wall to be demolished, and the calculation model is determined according to the simply supported beam. The calculated span is taken from the demolished length of the bearing wall 12 in the existing masonry.

[0085] 2) The embedded double channel steel beam 15 is supported by the existing 200mm-300mm wall stacks on both sides of the wall to be demolished, and the calculation model is determined according...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com