Fixed element and fixed device and electric device using fixed element

A technology of fixing devices and fixing parts, which is applied in the direction of threaded fasteners, connecting components, electrical components, etc., can solve the problems of increasing production costs, falling off, gasket deformation, etc., and achieves the advantages of saving assembly costs, convenient installation, and saving material costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

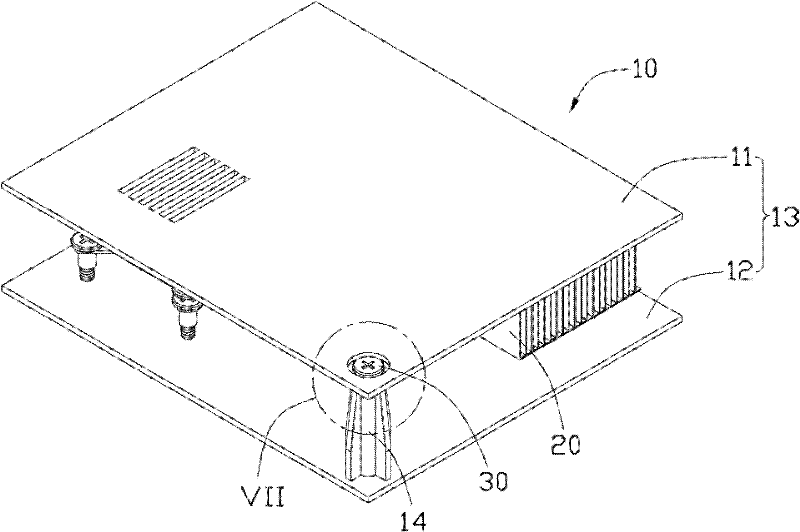

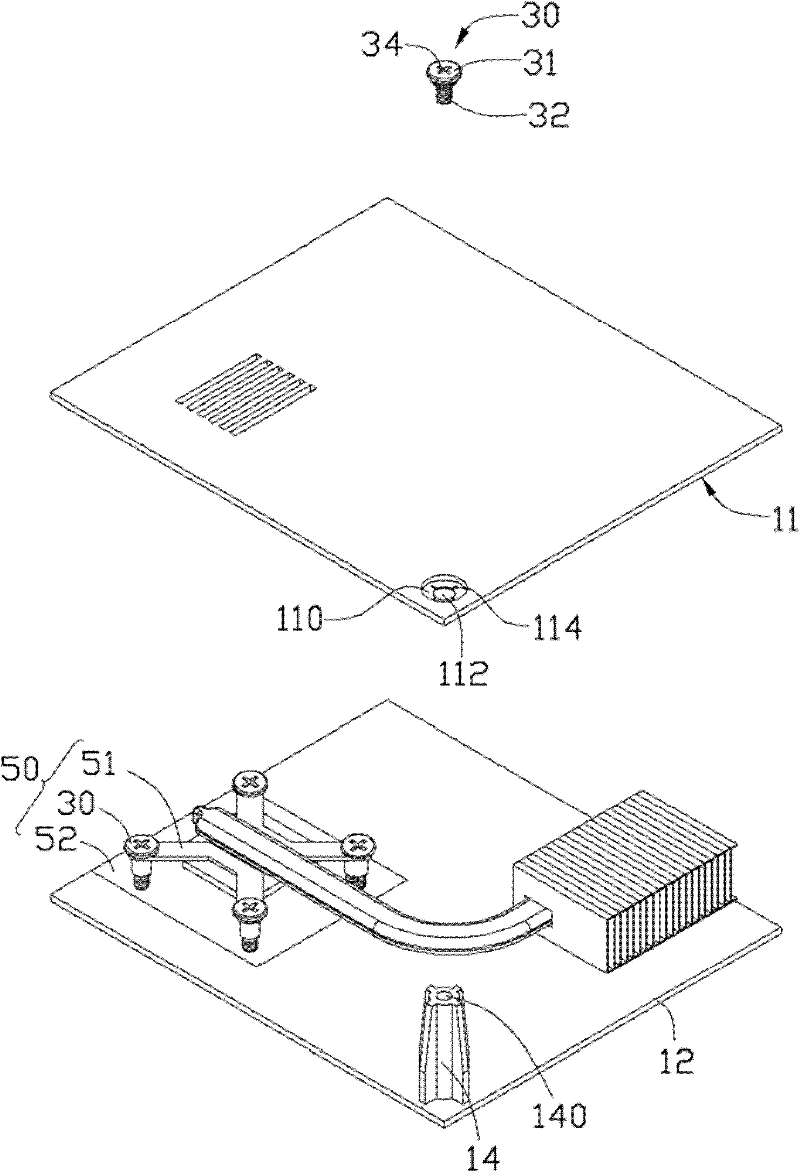

[0019] see figure 1 and figure 2 , is an electronic device 10 provided by an embodiment of the present invention, which includes a housing 13, a heat sink 20 accommodated inside the housing 13, and a fixing device for fixing the heat sink 20 inside the housing 13 50.

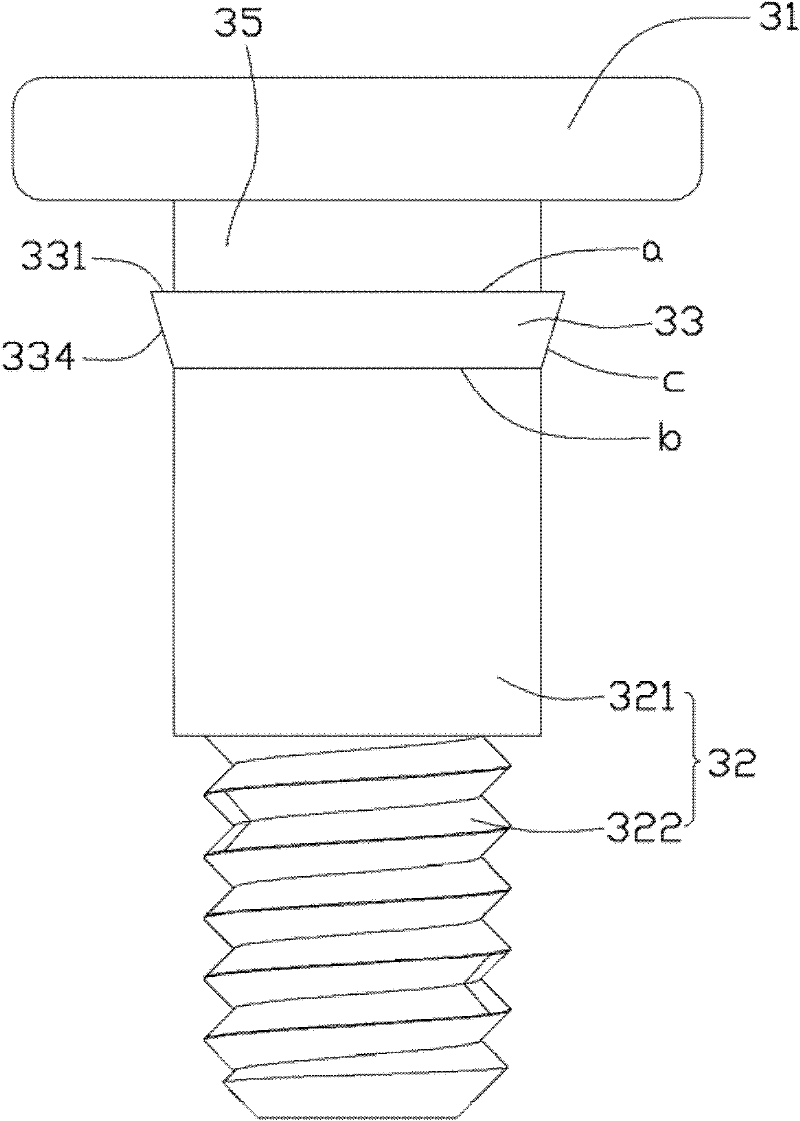

[0020] The housing 13 includes a rectangular bottom plate 12 and a top plate 11 opposite to the bottom plate 12 . The top plate 11 and the bottom plate 12 are parallel to each other. A corner of the bottom plate 12 extends vertically toward the direction of the top plate 11 to form a fixing column 14 . A threaded hole 140 is defined in the center of the fixing column 14 , and a plurality of internal threads are formed in the inner surface thereof. A corner of the top plate 11 is provided with a circular depression at a place facing the fixing column 14 . The plate body 110 in the recess of the top plate 11 has a relatively small thickness, and the center of the plate body 110 is provided with a through hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com