A rotating locking mechanism

A technology of locking mechanism and installation mechanism, applied in the field of shower room, can solve the problems of complicated production and assembly, occupying space, affecting appearance, etc., and achieves the effect of good performance, simple structure, and avoiding hard contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

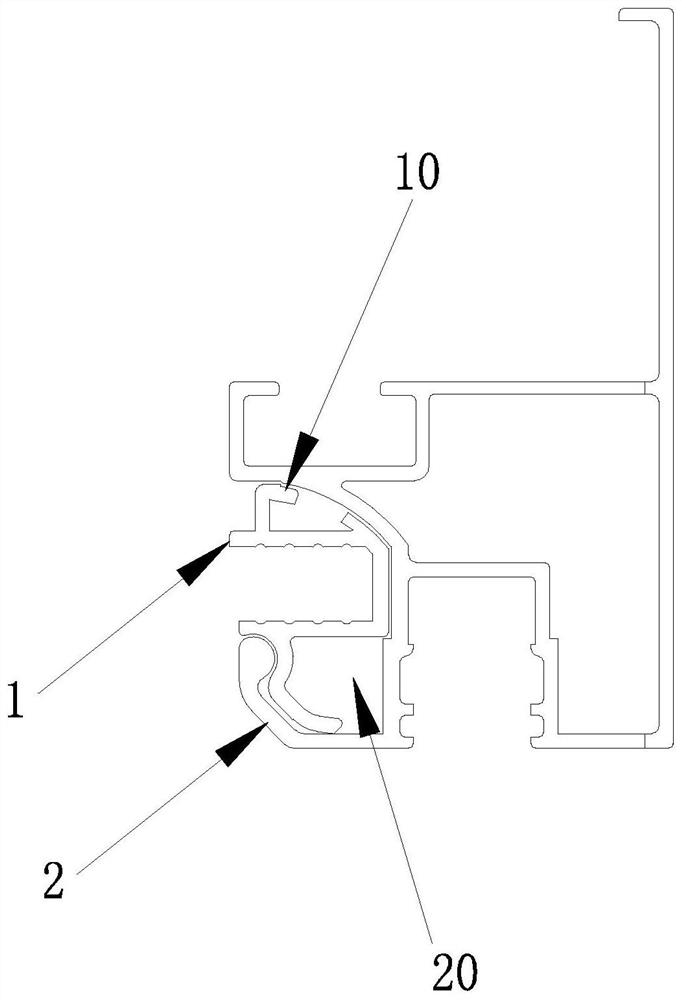

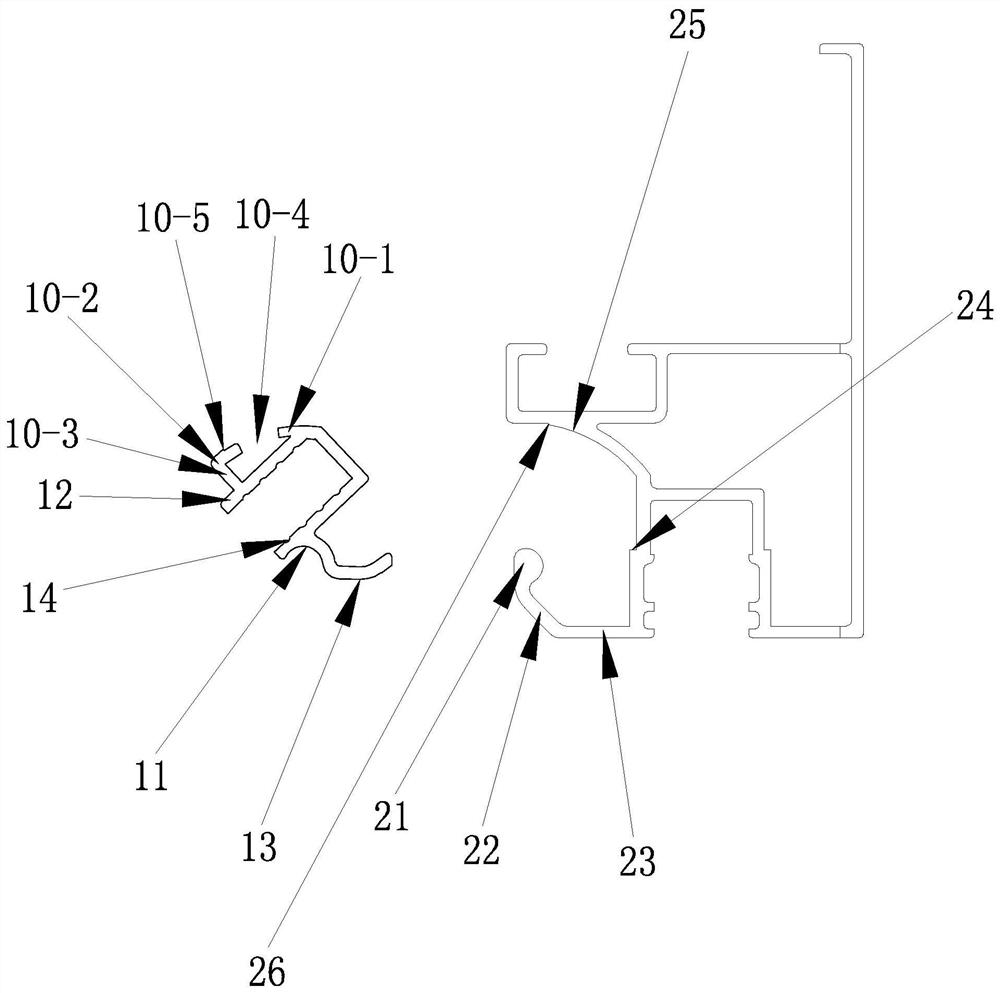

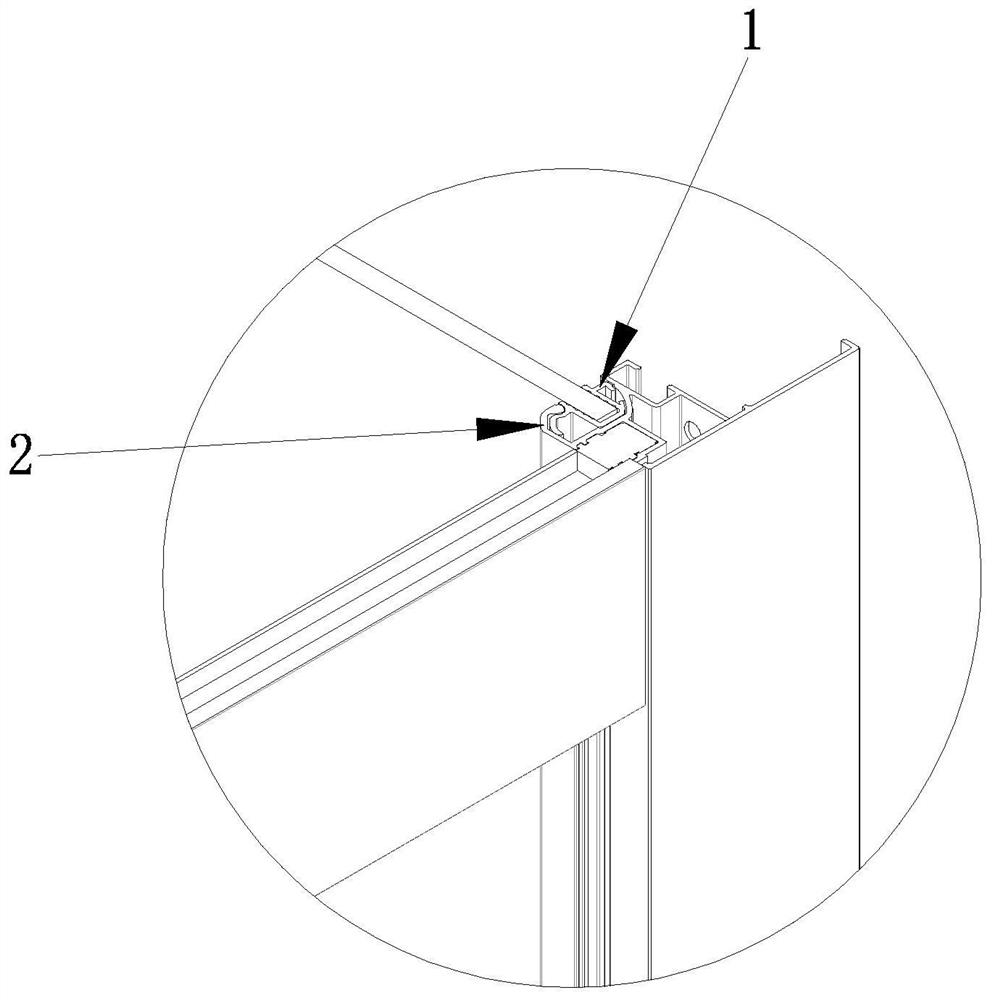

[0033] Example: Figure 1-3 As shown in a rotatably mounted locking mechanism, comprising a connecting mechanism forming aluminum production and mounting mechanism 2 1; 2 of the mounting mechanism formed on the mounting groove 20; the upper side of the mounting means 2 for forming a the connection means for rotation with the positioning protrusions 21, the end portion of the stopper protrusion 21 has an arc structure; Correspondingly, the stopper convex portions is formed on the connecting means 21 was adapted to the arcuate configuration of the connecting groove 11, connecting groove 11 and a connecting means mounted rotary connector mechanism 21 on the stopper protrusion portion 2, so that the connecting device 1 fit within the mounting groove 20 to achieve connection 1 and the mechanism 2 of the quick lock mounting mechanism; the present invention is simple in structure, easy to use, rotatably connected to the mounting means by the connection means, to achieve a rapid locking as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com