Long-acting flame-retardant treatment method suitable for wicker artware

A technology of flame retardant treatment and treatment method, which is applied in the field of long-term flame retardant treatment of wicker handicrafts, can solve the problems of unreachable flame retardant effect of willow handicrafts, adverse effects of willow material stability, loss of flame retardant effect, etc., to achieve Significant flame retardant effect, large specific heat capacity, and strong loss resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

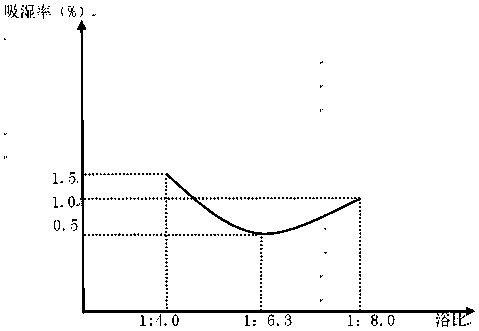

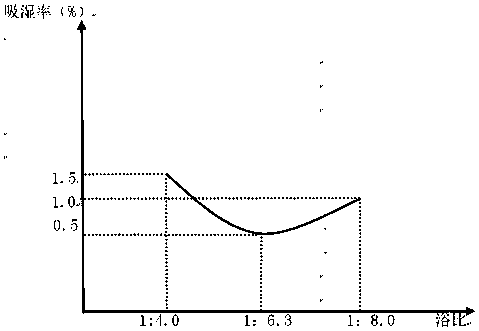

Image

Examples

Embodiment 1

[0018] A long-term flame-retardant treatment method suitable for wicker handicrafts. The prepared flame-retardant material is infiltrated into the willow material by means of atmospheric pressure heating and impregnation, and then dried to endow the weaving raw material with lasting flame retardancy. one-step weaving process;

[0019] Preferably, the preparation method of the flame retardant material comprises the following process steps:

[0020] Step 1: Weigh 70 grams of blast furnace slag, add it to 120 milliliters of concentrated sulfuric acid solution with a mass concentration of 90% under stirring, continue to stir for 1 hour, cool to 5 ° C, add 15 milliliters of hydrogen peroxide aqueous solution and 80 gram of sodium silicate solution, heated to 40°C and continued to stir for 30 minutes, and stood still at 60°C for 20 hours to obtain a precipitate, which was centrifugally washed twice with a hydrochloric acid solution with a mass concentration of 1.5%, and then washed ...

Embodiment 2

[0024] A long-term flame-retardant treatment method suitable for wicker handicrafts. The prepared flame-retardant material is infiltrated into the willow material by means of atmospheric pressure heating and impregnation, and then dried to endow the weaving raw material with long-lasting flame retardancy. one-step weaving process;

[0025] Preferably, the preparation method of the flame retardant material comprises the following process steps:

[0026] Step 1: Weigh 75 grams of blast furnace slag, add it to 125 milliliters of concentrated sulfuric acid solution with a mass concentration of 91% under stirring, continue to stir for 1.5 hours, cool to 8 ° C, add 18 milliliters of hydrogen peroxide aqueous solution and 85 gram of sodium silicate solution, heated up to 43°C and continued to stir for 35 minutes, and stood still at 65°C for 22 hours to obtain a precipitate, which was centrifuged and washed twice with a hydrochloric acid solution with a mass concentration of 1.8%, and...

Embodiment 3

[0030] A long-term flame-retardant treatment method suitable for wicker handicrafts. The prepared flame-retardant material is infiltrated into the willow material by means of atmospheric pressure heating and impregnation, and then dried to endow the weaving raw material with lasting flame retardancy. one-step weaving process;

[0031] Preferably, the preparation method of the flame retardant material comprises the following process steps:

[0032] Step 1: Weigh 80 grams of blast furnace slag, add it to 130 milliliters of concentrated sulfuric acid solution with a mass concentration of 92% under stirring, continue to stir for 2 hours, cool to 10 ° C, add 20 milliliters of hydrogen peroxide aqueous solution and 90 gram of sodium silicate solution, heated up to 45°C and continued to stir for 40 minutes, and stood still at 70°C for 24 hours to obtain a precipitate, which was centrifuged and washed 3 times with a hydrochloric acid solution with a mass concentration of 2.0%, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com