Bearing base aging treatment method and device capable of realizing temperature-force coupling loading

A loading device and aging treatment technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve problems affecting the service life of bearings, host reliability, bearing precision loss, dimensional changes, etc., to avoid adverse effects and ensure accuracy and life , the effect of reducing size distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

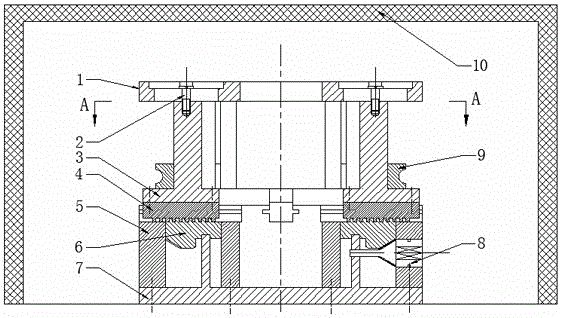

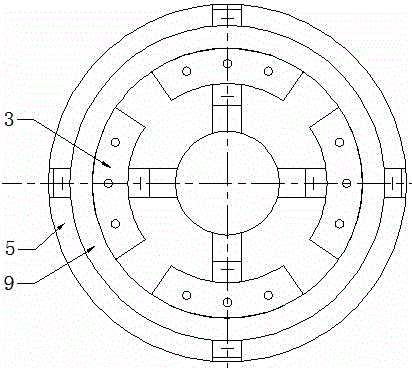

[0017] Such as Figure 1-4 As shown, a bearing matrix aging treatment method that can realize temperature-force coupled loading includes the following steps:

[0018] 1) Prepare a bearing matrix aging treatment device that can realize temperature-force coupling loading: it includes a force coupling loading device and a temperature control box 10 with a heating furnace;

[0019] The force coupling loading device includes an upper cover 1, a locking bolt 2, an arc-shaped pressure block 3, a slider 4, a housing 5, a large bevel gear 6, a base 7, and a small bevel gear 8; There are sliding holes, four arc-shaped pressing blocks 3 and four locking bolts 2 respectively (the four locking bolts 2 respectively pass through the sliding holes in the front, rear, left, and right directions of the upper cover 1), and the four arc-shaped pressing blocks 3 are all located on the upper cover 1, and distributed in the front, rear, left, and right directions, the lower end of the locking bolt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com