Phase change energy storage element

A technology of phase change energy storage and components, applied in heat storage equipment, lighting and heating equipment, heat exchanger shells, etc., can solve the problems of phase change material leakage and heat exchange efficiency, so as to ensure heat exchange efficiency and improve heat exchange Efficiency, effect of large dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

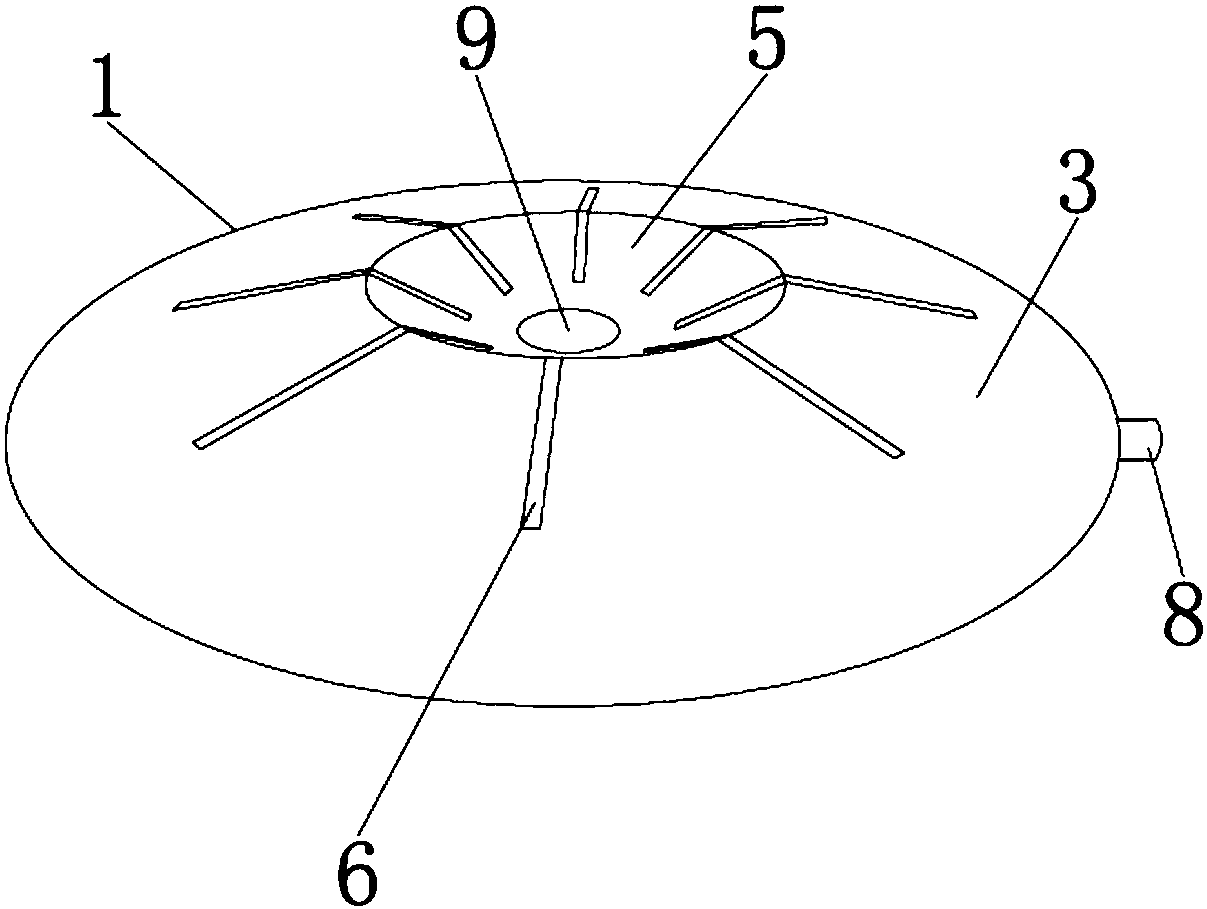

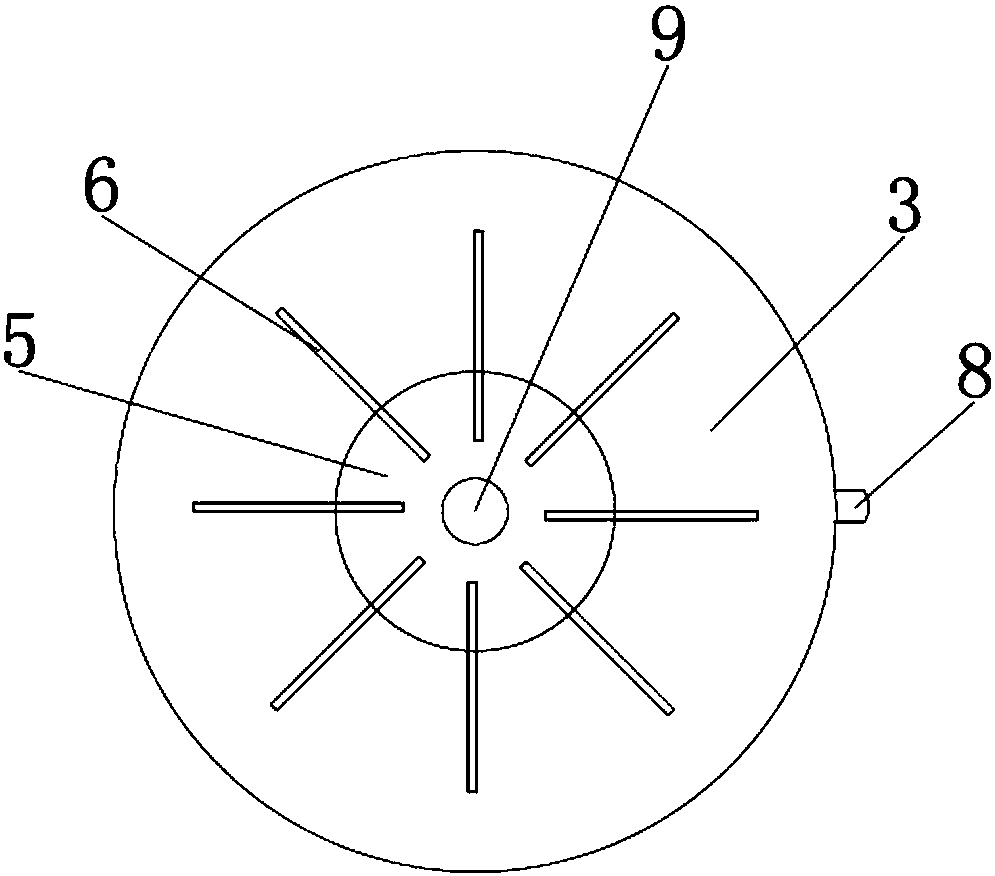

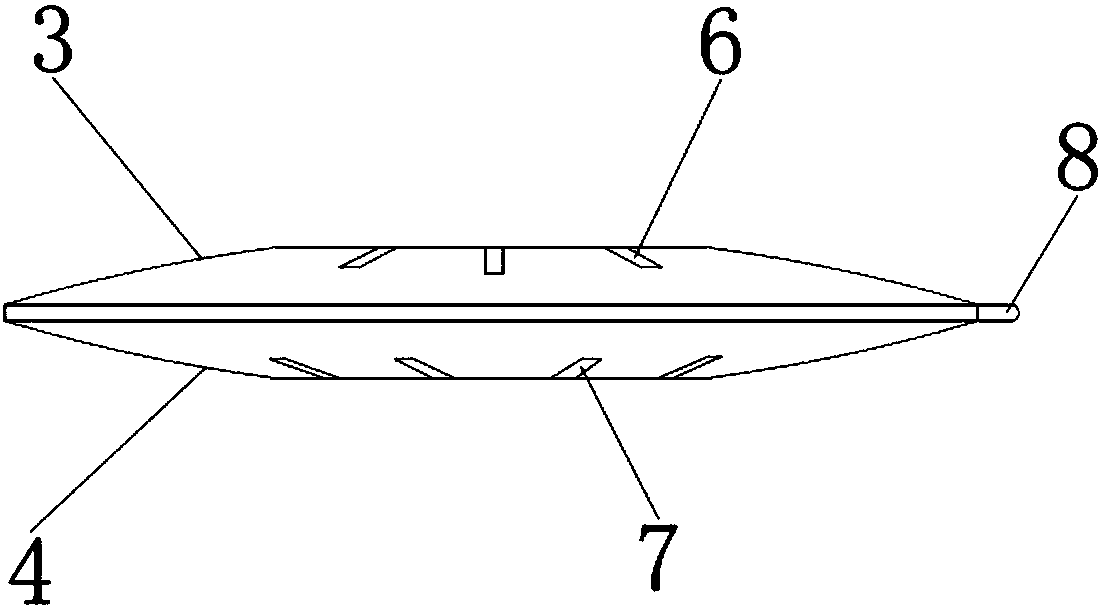

[0037] Such as figure 1 , 2 , 3, 4, 5, the phase change energy storage element is a closed system surrounded by a plastic shell 1, the shell 1 is preferably thermoplastic, more preferably polyethylene, polypropylene, polyamide or polycarbonate, the shell 1 The top view shape of the shell is circular, elliptical or rectangular, and the shape of the shell 1 is similar to that of a convex lens, with a thick center and a thin edge.

[0038] The housing 1 includes a top surface 3 and a bottom surface 4, which are arranged symmetrically, and the top surface 3 and the bottom surface 4 are respectively curved surfaces protruding outward. The top surface 3 is provided with a first central depression 5, and eight first grooves 6 are arranged around the first central depression 5, and one end of the first groove 6 extends into the first central depression 5, adjacent to the first depression. The included angle of the groove 6 is 45°, which ensures the contact area and uniformity betwee...

Embodiment 2

[0043] The difference from Embodiment 1 is that the phase-change energy storage element does not include through holes, and when the phase-change energy storage element is in contact with the heat-conducting medium, the heat-conducting medium is located on the outer surface of the phase-change energy storage element.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Maximum width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com