Gas stove front valve automatic control device

An automatic control device and gas stove technology, which is applied in the direction of heating fuel, household stove/stove, gaseous heating fuel, etc., can solve the problems of gas leakage, safety hazards not completely eliminated, and long time required to eliminate gas explosions hidden dangers, improve practical safety, and reduce the effect of electrification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

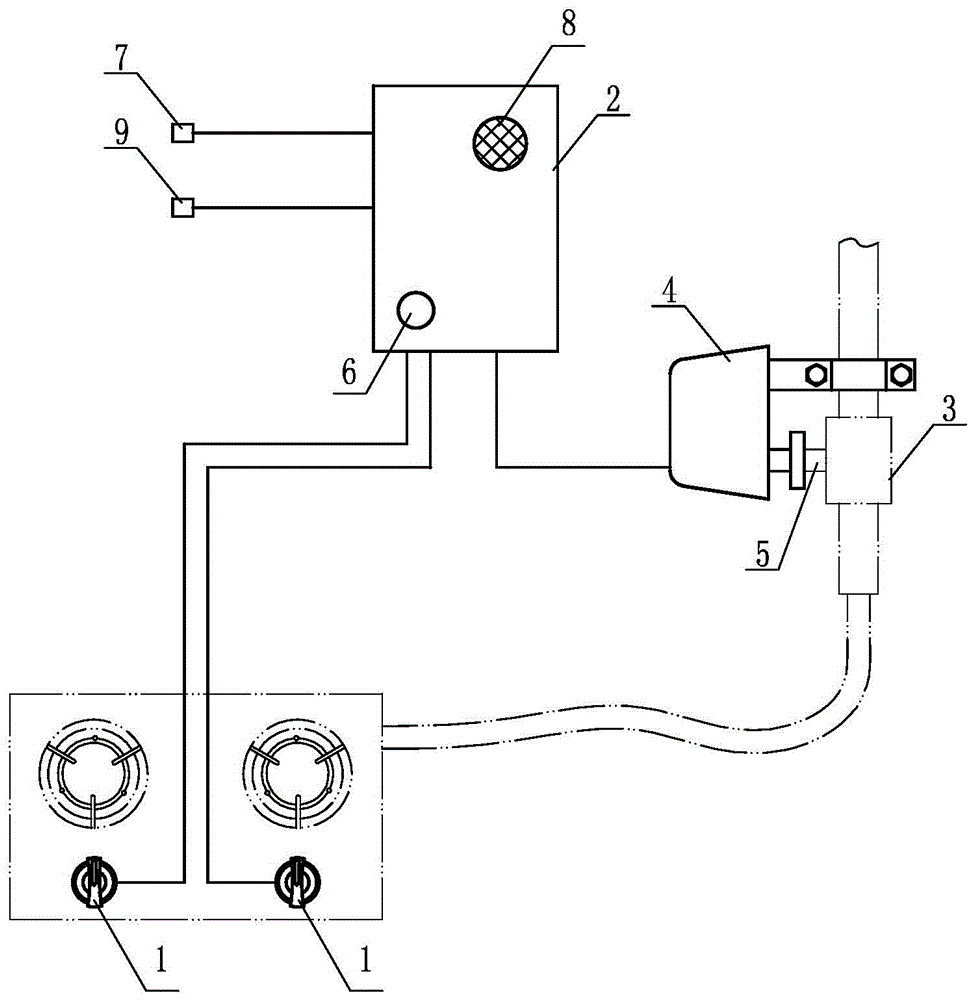

[0020] Such as figure 1 As shown, the automatic control device for the front valve of the gas stove is arranged between each ignition switch 1 of the gas stove and the front valve 3 of the stove, and includes a controller 2, and each of the ignition switches 1 is connected to the controller 2 Signal input end, the output end of the controller 2 is connected with a gas valve control manipulator 4, and the gas valve control manipulator 4 is fixedly installed on the gas pipeline and connected to the control handle 5 of the front valve 3 of the stove. The outer periphery of the control handle 5 is covered with an insulating sleeve, the purpose is to avoid static electricity and improve the safety of use. The gas valve control manipulator 4 is in contact with the insulated control handle 5, so that the gas valve control manipulator 4 can be The electrical components on the side are electrically isolated from the gas pipeline and the front valve 3 to prevent the electricity of the g...

Embodiment 2

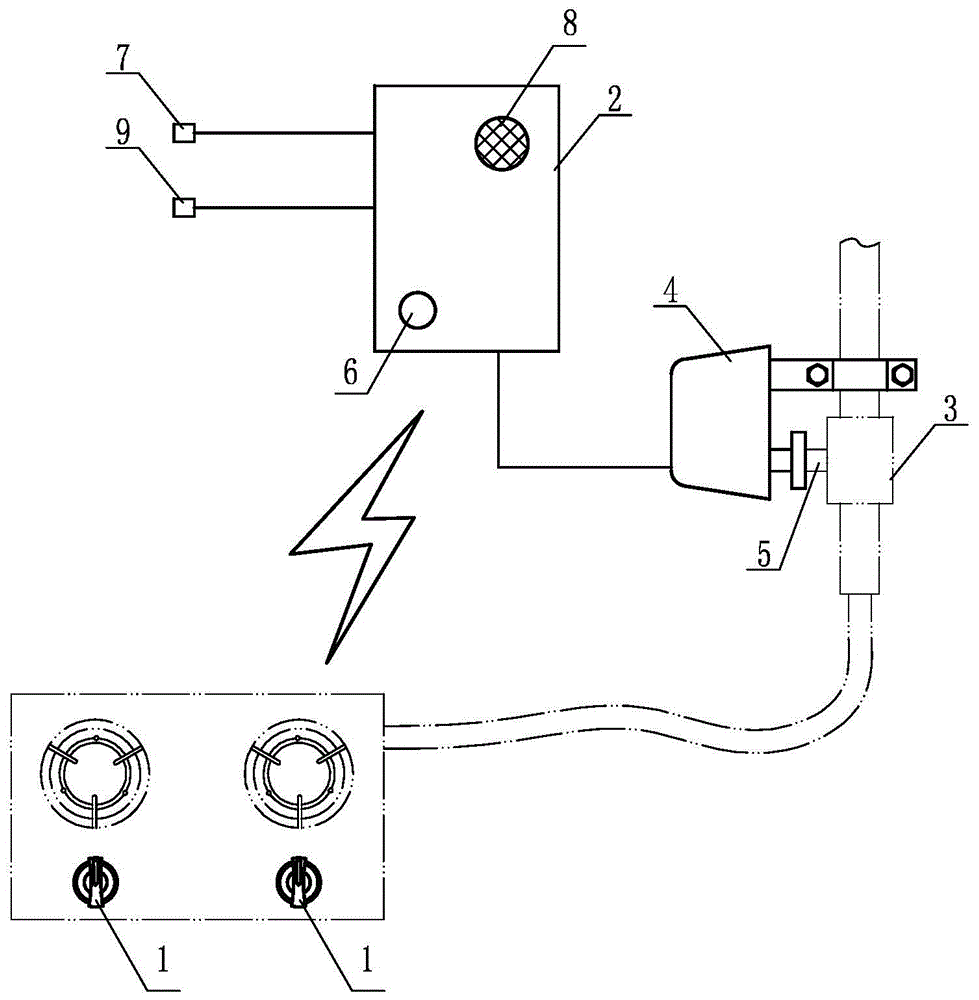

[0029] Such as figure 2 As shown, the difference between this embodiment and Embodiment 1 is that: the communication mode between the controller 2 and the ignition switch 1 is different. In this embodiment, each of the signal input ends of the controller 2 The signal channel is a wireless channel, so that the wiring of the wired channel can be avoided, and the use is more convenient.

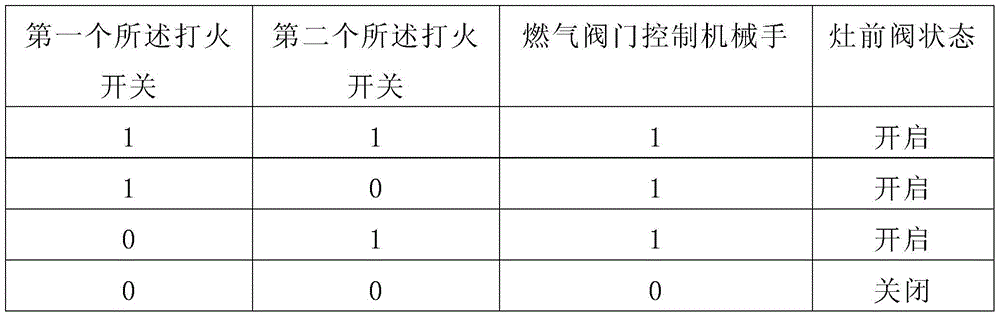

[0030] The control method of above-mentioned two embodiments is identical, and its concrete process is as follows:

[0031] Step 1. Signal Acquisition

[0032] When any one of the ignition switches on the gas stove is turned on, a start control signal is generated to the controller, and the controller sends an opening signal to the gas valve control manipulator, and the gas valve control manipulator moves The valve in front of the stove is driven to open, and the burner of the gas stove is safely ignited and burned.

[0033] When all the ignition switches are turned off, that is, when all ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com