Method for treatment of metal waste water by sulfate reducing bacteria growing up with electric current

A sulfate and heavy metal technology, applied in biological water/sewage treatment, mining wastewater treatment, metallurgical wastewater treatment, etc., to achieve the effect of low potential, avoid secondary pollution, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

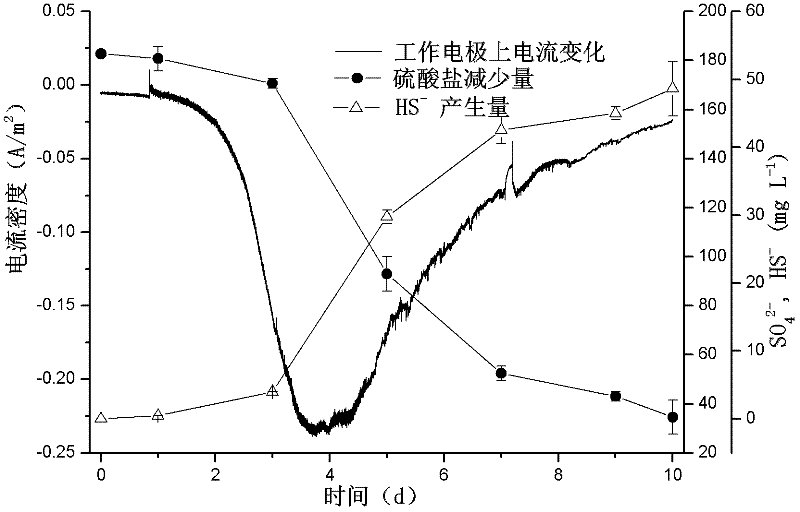

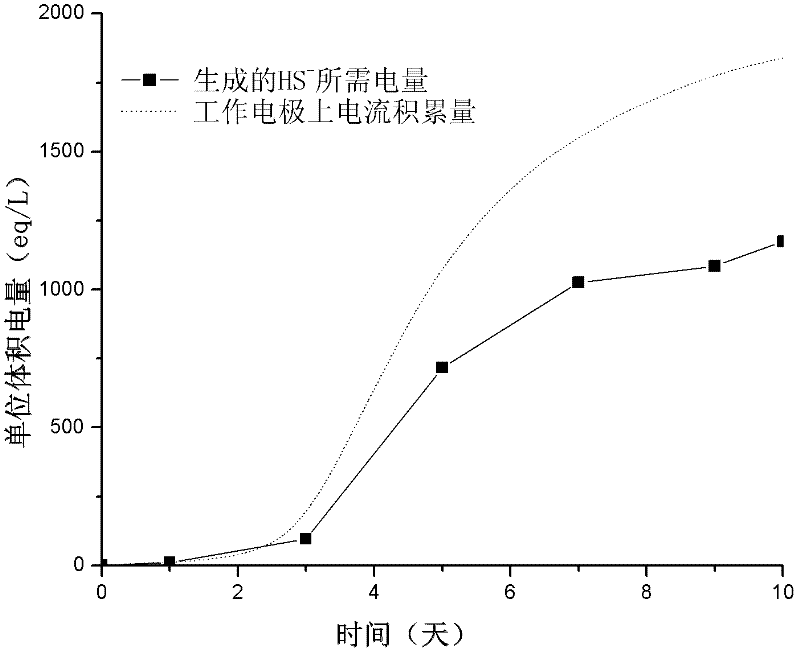

[0033] Example 1: Sulfate Reduction and Sulfide Generation Using Electrode as the Only Electron Donor

[0034] Construction of bioelectrochemical reaction device

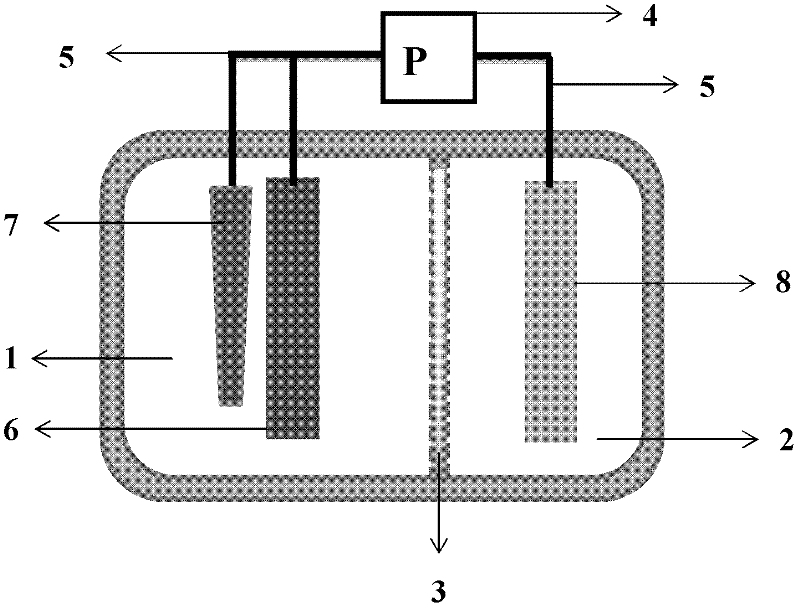

[0035] The bioelectrochemical device is a double-chamber reactor configuration ( figure 1 ), including potentiostat 4, wire 5, cathode chamber 1 and anode chamber 2. A working electrode 6 and a reference electrode 7 are inserted into the cathode chamber 1, and activated sludge from a municipal sewage plant is added; an auxiliary electrode 8 is inserted into the anode chamber 2; the two chambers are separated by a diaphragm 3 .

[0036] Preparation of cathodic and anode compartment solutions

[0037] Anode chamber

[0038] 0..05mol / L phosphate buffer solution (pH 7.0)

[0039] Cathode chamber

[0040] Na 2 HPO 4 12H 2 O 10.9g L -1 , NaH 2 PO 4 3.0 g L -1 , NaHCO 3 2.0gL -1 , KCl 100mg L -1 , MgCl 2 40mgL-1 , NH 4 Cl 310mgL -1 , CaCl 2 50mgL -1 , NaCl 10 mg L -1 , FeCl 2 25mgL -1 , CoCl 2 ...

Embodiment 2

[0054] Embodiment 2: sulfide reduction metal copper ion test

[0055] The soluble sulfides produced by sulfate reducing bacteria are S 2- 、HS - 、H 2 S, their morphology is related to pH, according to literature reports, when pH2 The concentration of S is relatively large, and HS is between pH 7-13 - Mainly, pH>13 with S 2- Mainly. Carry out the operation of bioelectrochemical reaction according to the step of embodiment 1, because catholyte contains buffer solution, pH about 8 after sulfate reduction, sulfide in catholyte should be HS - Mainly, therefore, when the sulfide concentration in the reactor continues to reach above 50mg / L, the reactor effluent is passed into the reactor containing 100mg / L Cu in a ratio of 1:1 2+ Copper sulfide precipitates are formed after low-concentration wastewater, and Cu in wastewater is detected 2+ Content, Cu in the supernatant after precipitation 2+ Content below 5mg / L, Cu 2+ The removal rate is greater than 95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com