Method for recycling tin

A technology of tin plating and detinning, applied in the field of tin recycling, to achieve the effect of simple process, good labor conditions and less equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

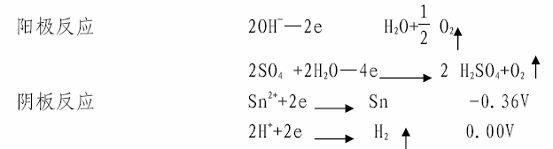

Image

Examples

Embodiment Construction

[0015] The gist of the present invention is to repair the old and benefit the waste, and to contribute to the green economy by saving energy, reducing consumption and environmental protection through waste recycling that benefits the country and the people. For this reason, the invention provides a kind of method that reclaims tin, and the tin recovery solution that this method uses is made of solute Cu2 + 10~60g / l,H 2 SO 4 40~100g / l and solvent distilled water, the method steps are as follows:

[0016] (1) Put the tin-plated scrap copper into the leaching basket, which is welded with Gr18Ni9Ti stainless steel, and the surrounding is made of 40-60 mesh stainless steel mesh, which is convenient for the solution to drain, and the bottom is an openable bottom, which is convenient for unloading.

[0017] (2) Hang the loaded basket into the replacement tank for soaking and detinning. The solution in the replacement tank contains Cu10~60g / l, H 2 SO 4 50~100g / l, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com