Laser cutting plate waste material separation part sorting system

A laser cutting and sorting system technology, applied in solid separation, magnetic separation, laser welding equipment, etc., can solve problems such as a large number of unfavorable suction cups, easy to fall into dust and debris, and reduce reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

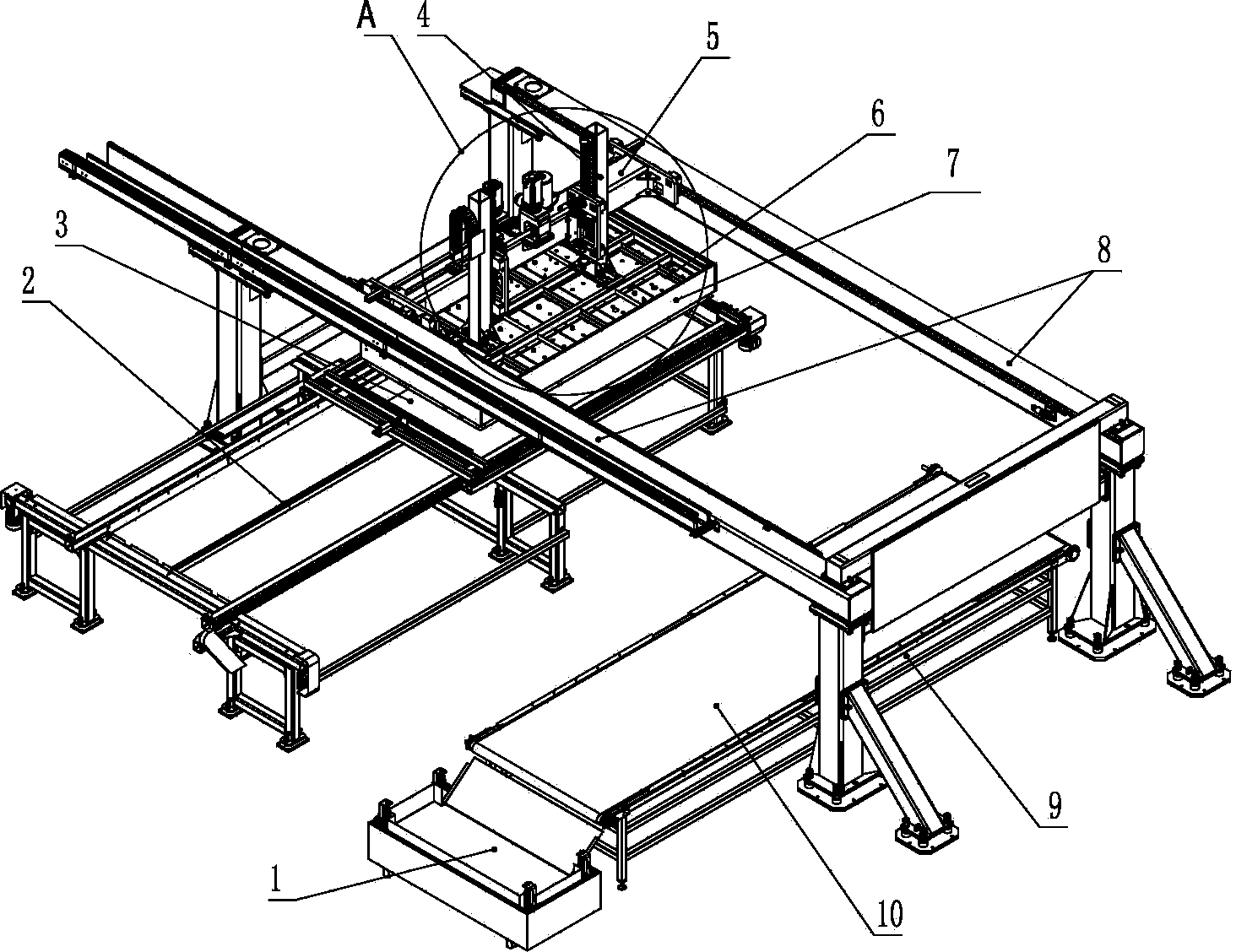

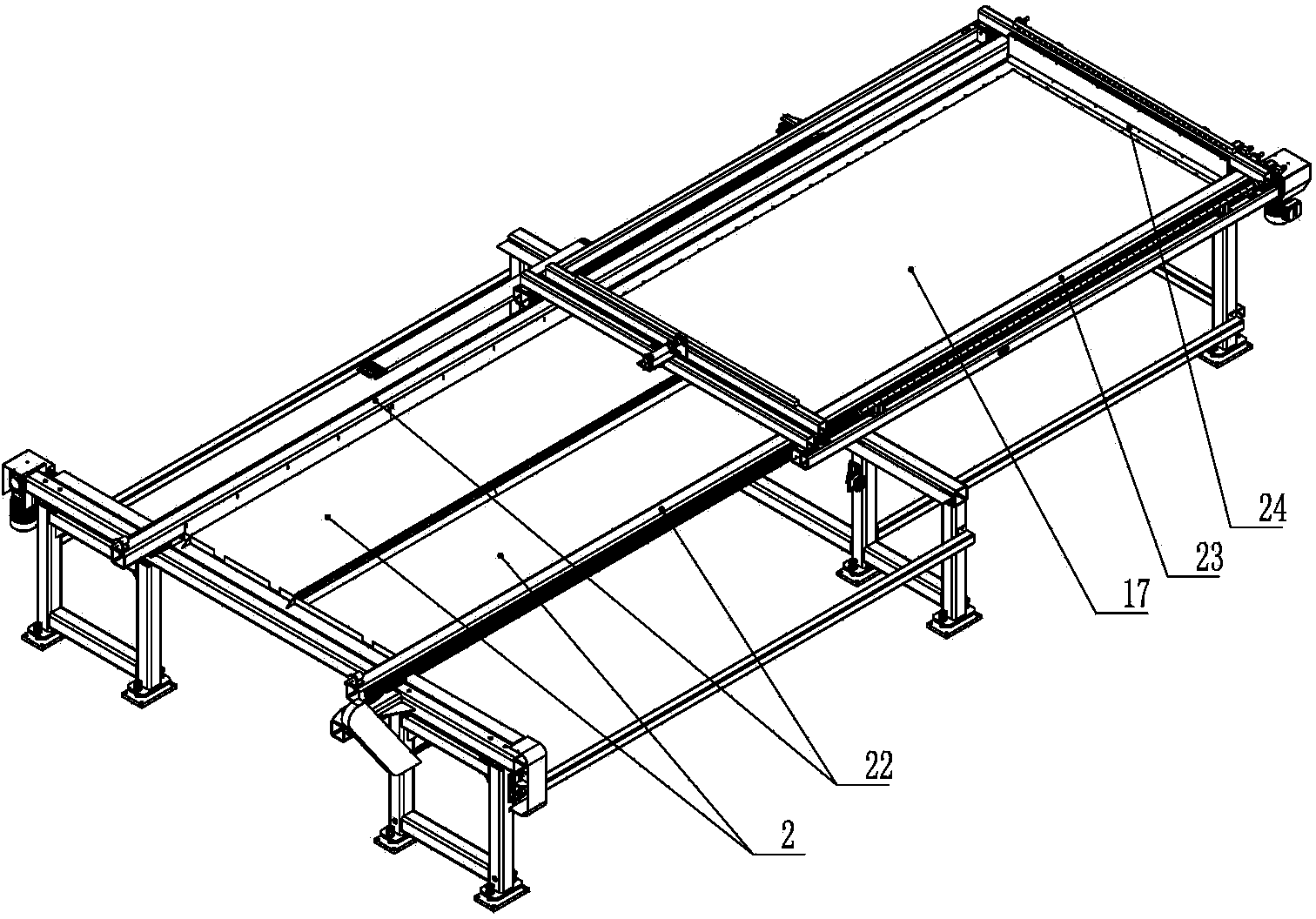

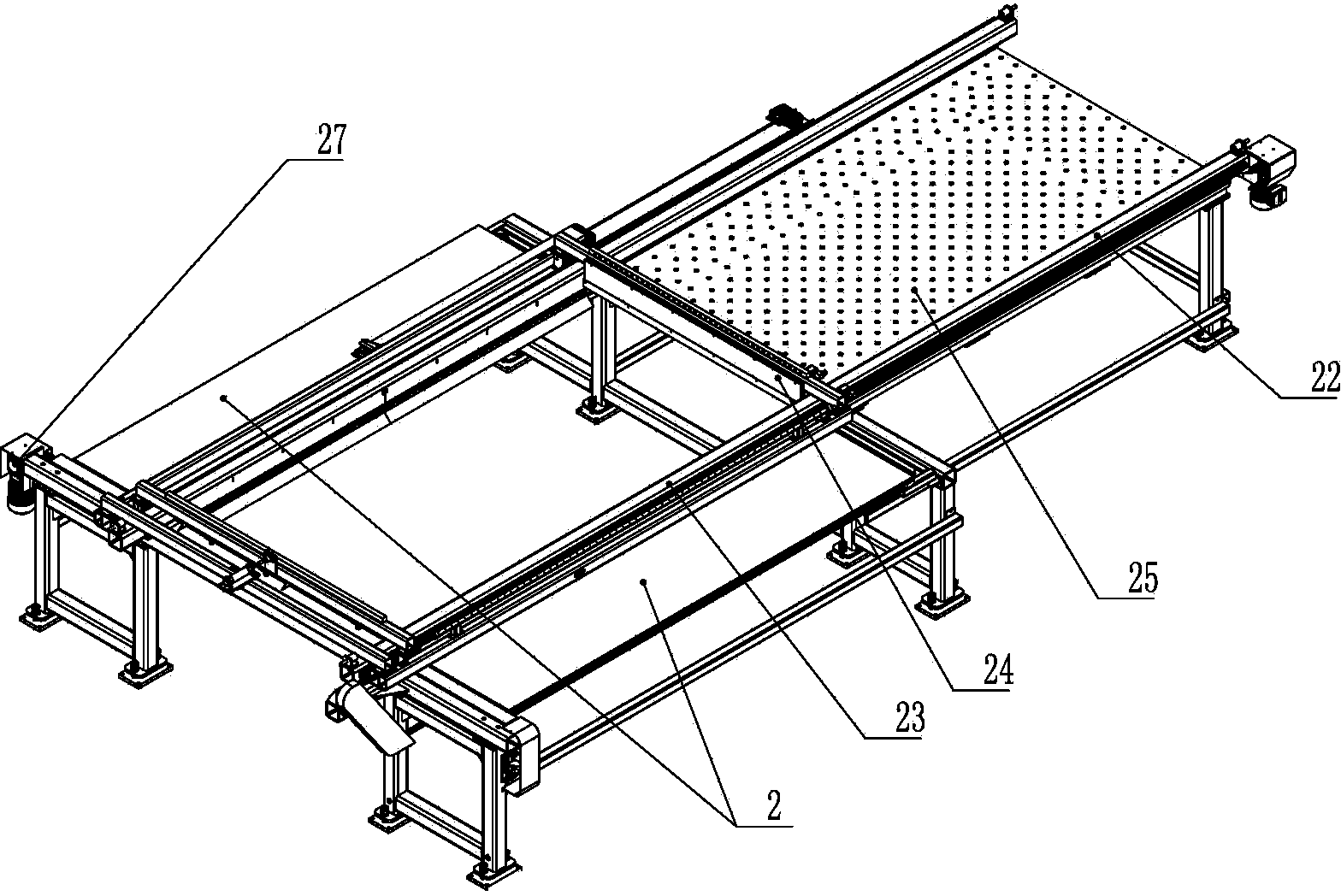

[0021] As shown in the figure, it is a laser cutting plate waste separation and parts sorting system. Its structure includes two support beams 8 arranged in parallel, a beam 5 is connected between the support beams 8, and a horizontal movement mechanism 15 is arranged at both ends of the beam 5 It is connected with the support beam 8 so that the cross beam 5 can slide horizontally along the support beam 8. The lifting column 4 is connected to the cross beam 5 through the lifting transmission mechanism. The lifting transmission mechanism includes a servo motor 20. Case 14 both sides protrudes transmission shaft 19 respectively, and transmission shaft 19 is rotatably connected on the sliding support 11, and lifting column 4 is provided with rack 12 and column guide rail 13 respectively, and sliding support 11 is provided with and column guide rail 13 slides. The connected column slider, the shaft end of the transmission shaft 19 is provided with a gear to mesh with the rack 12; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com