Processing method of chemical nickel phosphor plating

An electroless nickel-plating phosphorus and treatment method technology, which is applied in chemical instruments and methods, metallurgical wastewater treatment, water/sewage treatment, etc., can solve the problems of complex process, high cost of raw materials, high energy consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

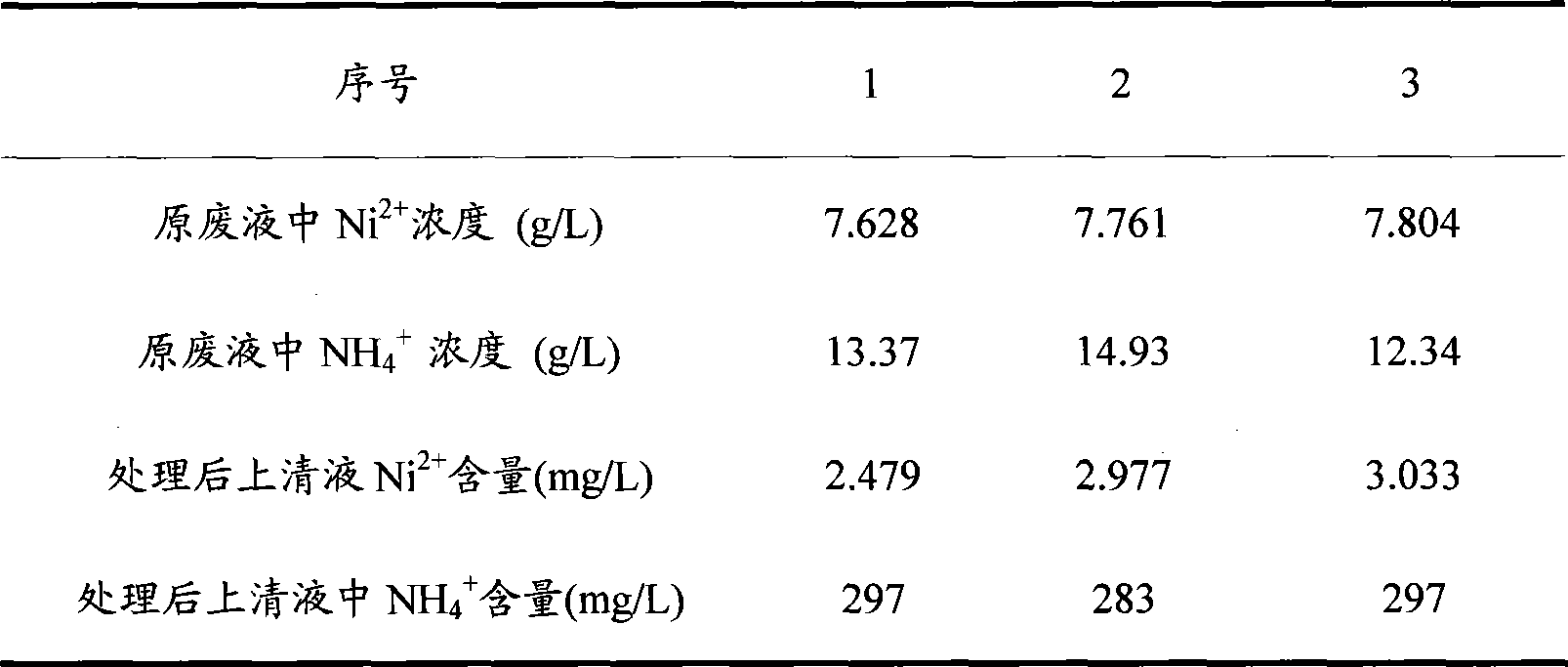

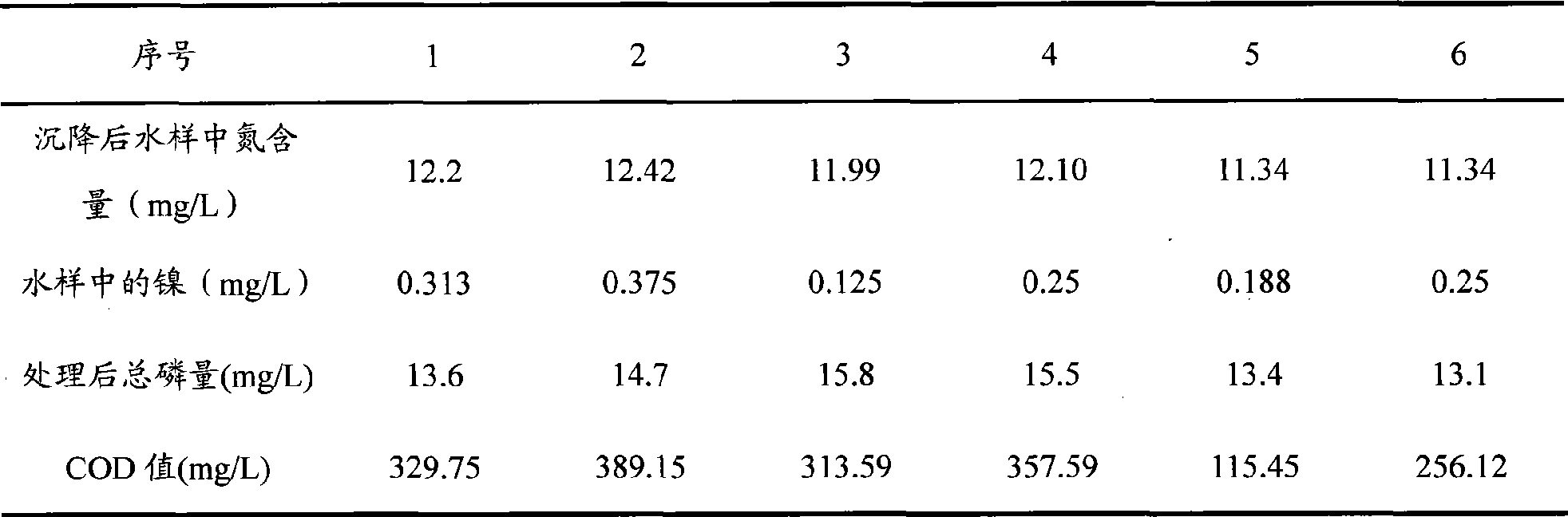

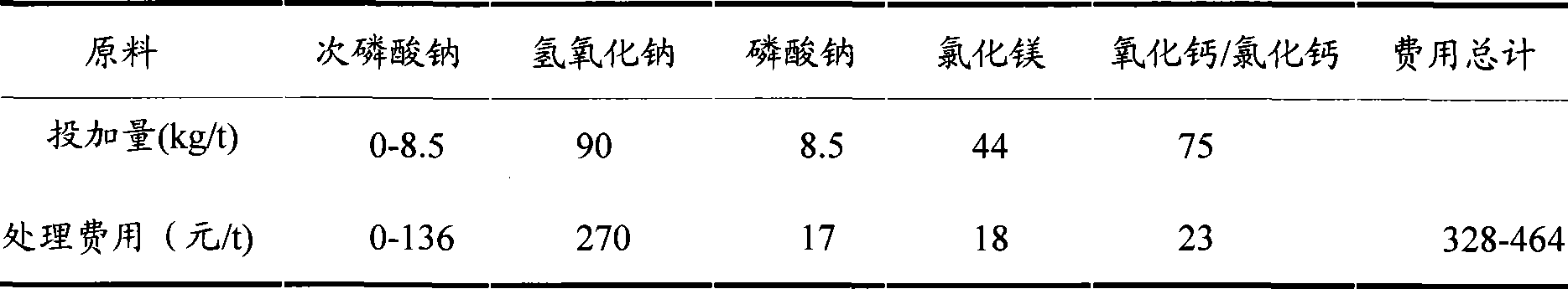

Embodiment 1

[0035] Add sodium hypophosphite to the waste liquid to adjust the nickel-phosphorus ratio of the waste liquid to 0.7, then add 80g / L NaOH solid until the pH of the waste liquid is 13, and the solution will be released rapidly in the form of ammonia gas during the decomposition process, making the waste liquid When the concentration of ammonia nitrogen drops to 150mg / L, follow n[NH 4 + ]:n[PO 4 3- ]:n[Mg 2+ ]=1:1:12 add MgCl 2 , generate magnesium ammonium phosphate, precipitate until the ammonia nitrogen content drops below 14mg / L and filter, add 10% CaO solution 10mL / L and 20% CaCl to the resulting solution 2 Solution 7mL / L, filter the precipitate after static precipitation.

Embodiment 2

[0037] Add sodium hypophosphite to the waste liquid to adjust the nickel-phosphorus ratio of the waste liquid to 1.5, and then add 110g / L NaOH solid until the pH of the waste liquid is 14. During the decomposition process, the solution will be released rapidly in the form of ammonia gas, making the waste liquid When the concentration of ammonia nitrogen drops to 200mg / L, follow n[NH 4 + ]:n[PO 4 3- ]:n[Mg 2+ ]=1:1:8 add MgCl 2 , generate magnesium ammonium phosphate, precipitate until the ammonia nitrogen content drops below 14mg / L and filter, add 10% CaO solution 12mL / L and 20% CaCl to the resulting solution 2 Solution 10mL / L, filter the precipitate after static precipitation.

Embodiment 3

[0039] Add sodium hypophosphite to the waste liquid to adjust the nickel-phosphorus ratio of the waste liquid to 1.0, and then add 50g / L NaOH solid until the pH of the waste liquid is 12. The solution is released rapidly in the form of ammonia gas during the decomposition process, making the waste liquid When the concentration of ammonia nitrogen drops to 100mg / L, follow n[NH 4 + ]:n[PO 4 3- ]:n[Mg 2+ ]=1:1:10 add MgCl 2 , generate magnesium ammonium phosphate, precipitate until the ammonia nitrogen content drops below 14mg / L and filter, add 10% CaO solution 15mL / L and 20% CaCl to the resulting solution 2 Solution 5mL / L, filter the precipitate after static precipitation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com