Method for preparing LFT-D (long fiber reinforced thermoplastic composite) dung draining plate by utilizing production leftovers

A technology of LFT-D and leftovers, which is applied in the field of LFT-D production of leftovers to recycle and prepare new leaky dung boards, can solve the problem of recycling and reuse of LFT-D composite wastes, problems, and problems. Problems such as complete leaky dung panels and defective products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

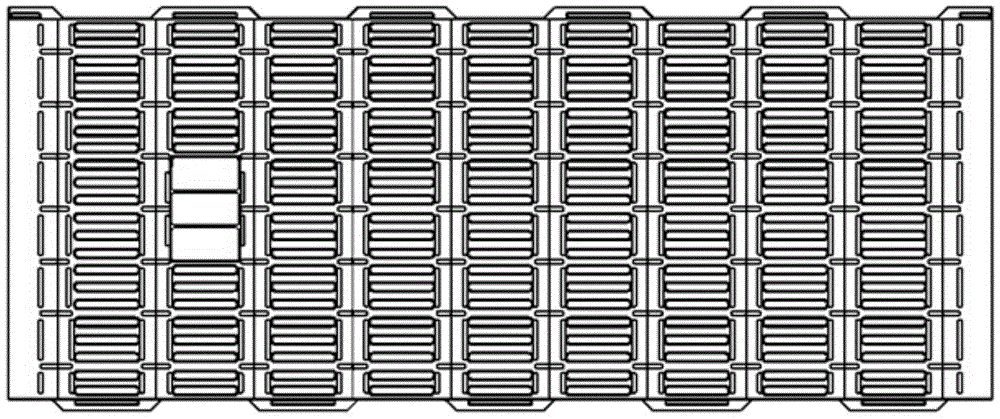

Image

Examples

Embodiment 1

[0034] The new material is made of PP resin, and the production scraps are recycled LFT-D manure leakage board fragments. The diameter of the crushed particles is about 5mm. The weight ratio of the production of scraps, virgin material and glass fiber is 11:3:6. The LFT-D fecal leakage board with a length, width and height of 1500×600×35 mm and a weight of 7.85 kg was prepared.

[0035] The strength test is carried out in accordance with the corresponding national standards. The pressure in the experiment is 1300T, and the pressure holding time is tens of seconds. The obtained indicators are as follows:

[0036] Bending strength: 24.4kgf, bending strength: 106.6MPa, bending modulus: 5Gpa, beam unnotched impact strength: 40.4kJ / m 2 Compared with products processed with new materials, some indicators have improved, and all of them exceed the strength indicators of the industry standard products.

Embodiment 2

[0038] The new material is made of PP resin, and the production scraps are recycled LFT-D manure leakage board fragments. The diameter of the crushed particles is about 5mm. The weight ratio of the production of scraps, virgin material and glass fiber is 1:3:2. The prepared LFT-D fecal leakage board is 1500mm×600mm×35mm in length, width and height respectively, and its weight is 7.9kg.

[0039] The strength test is carried out in accordance with the corresponding national standards, and the indicators are as follows: Tensile strength: 47.81Mpa Bending strength: 78.37Mpa Flexural modulus: 4.88Gpa, Support beam unnotched impact strength: 40.0kJ / m 2 , All exceed the strength indicators of the industry's standard products.

Embodiment 3

[0041] The new material is made of PP resin, and the production waste is recycled LFT-D dung leakage board fragments. The diameter of the crushed particles is about 8mm. The weight ratio of the production waste, the new material and the glass fiber is 1:4:1.8. The prepared LFT-D fecal leakage board with length, width and height of 1500mm×600mm×35mm and its weight of 7.95kg was tested in accordance with the corresponding national standards. The indicators are as follows: tensile strength: 47.85Mpa, bending strength : 78.41Mpa, flexural modulus of elasticity: 4.89Gpa, unnotched impact strength of support beam: 40.4kJ / m 2 , All exceed the strength indicators of the industry's standard products.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com