Deflection type servo feeding line

A technology of servo feeding and deflection, which is applied in the field of punch peripheral equipment, can solve the problems of high production cost, low production efficiency, and large production line space, so as to prevent internal stress rebound, reduce occupied space, and reduce plate waste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

[0037] The yaw-type servo feeding line of the present invention belongs to the peripheral equipment of the punching machine, and is mainly used for automatic feeding of the punching machine, that is, to accurately send the plate to be punched to the stamping station of the punching machine in a numerically controlled manner.

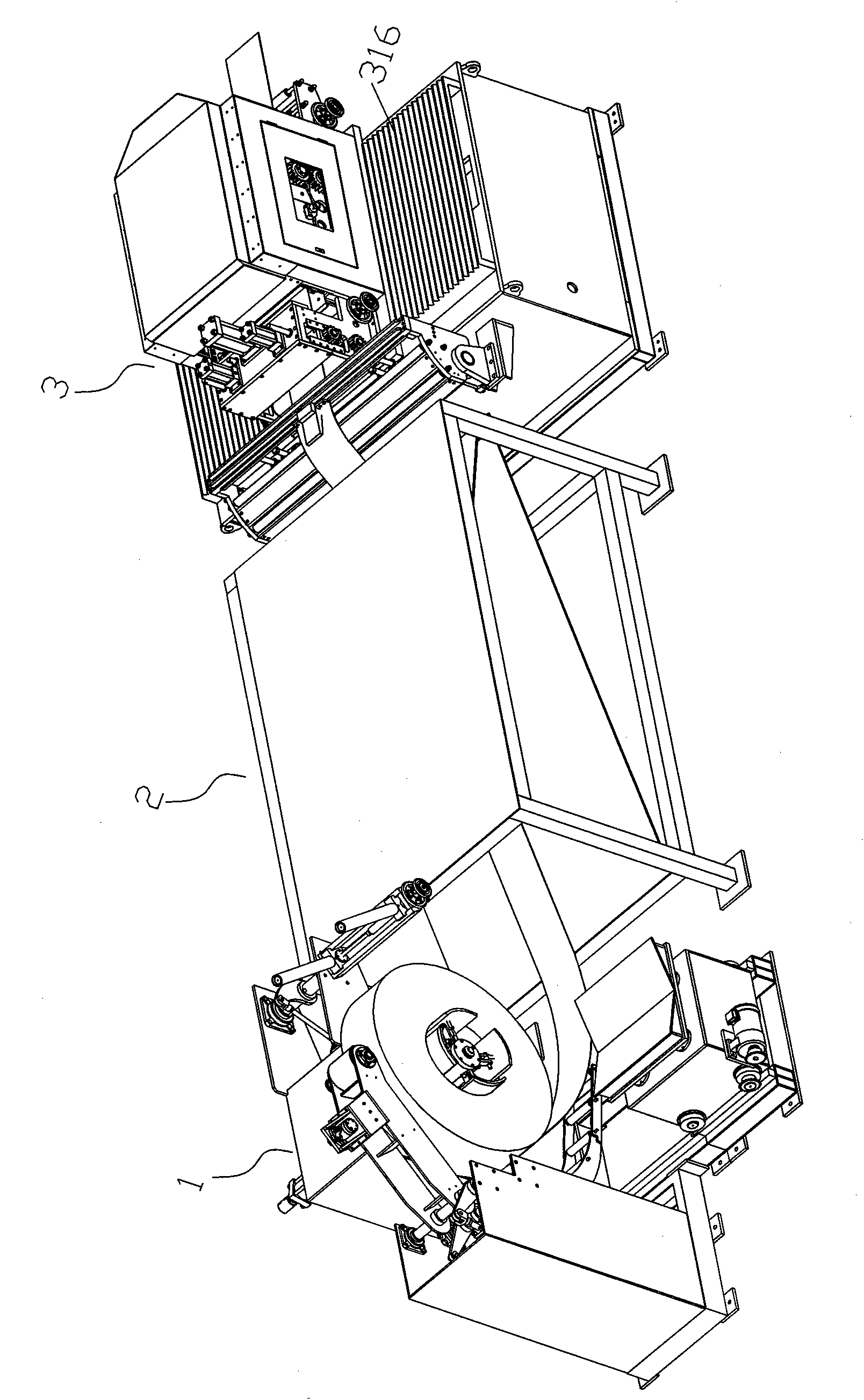

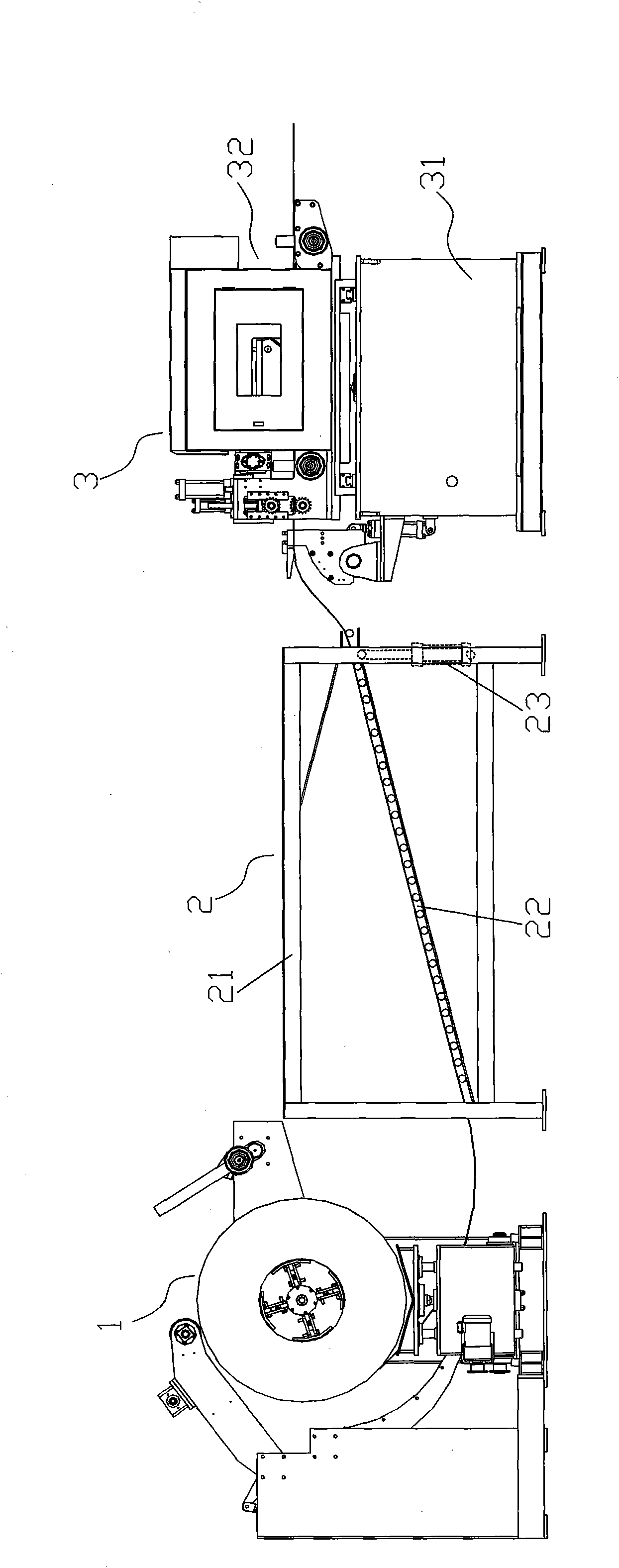

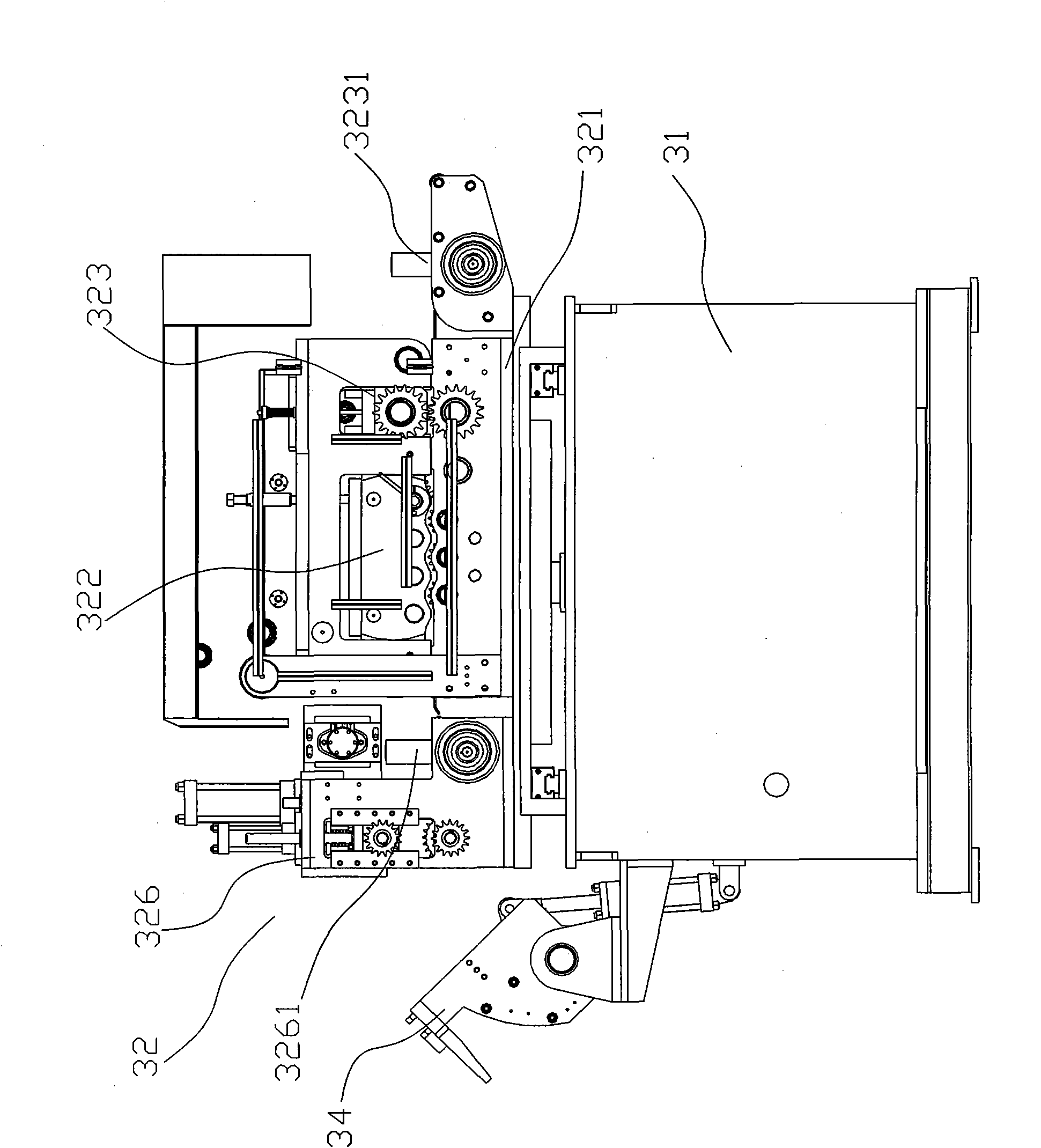

[0038] First, if figure 1 , 2 As shown, the yaw-type servo feeding line of the present invention includes an uncoiler 1, a transition frame 2, and a yaw-type feeding host 3 in sequence, wherein the uncoiler 1 is used to unfold the coiled plate under tension; the transition frame 2. It is used to accept the unfolded board. The board is transported to the yaw-type feeding host 3 through the transition frame 2. The yaw-type feeding host 3 levels and cuts the board and feeds it to the punching machine.

[0039] Specifically, co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com