ZrC-TiC modified C/C-SiC composite material and preparation method thereof

A composite material and modification technology, which is applied in the field of ZrC-TiC modified C/C-SiC composite material and its preparation, can solve the problems of material isolation, difficulty in SiC components, limiting material ablation resistance, etc. Short, suitable for a wide range of workpiece sizes, and has the effect of preventing erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

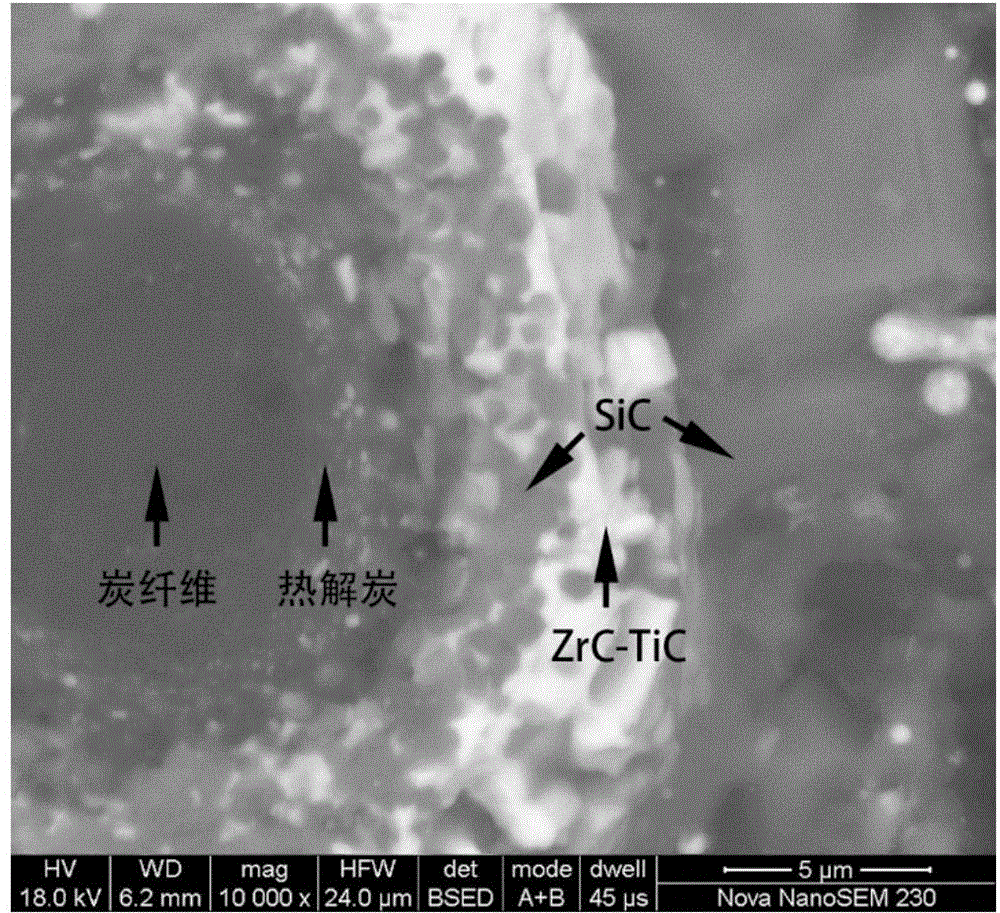

[0049] Set the density to 0.58g / cm 3 The carbon fiber fine-woven puncture felt is placed in a closed furnace cavity, methane and hydrogen are introduced, and the temperature is kept at 1100°C for 100h, and the pressure in the furnace is 1.6Kpa. The surface of the fibers in the carbon fiber braid is gradually deposited to form pyrolytic carbon by chemical vapor infiltration, and a density of 1.20 g / cm is obtained. 3 -1.33g / cm 3 The C / C composite material is prepared for subsequent steps after ultrasonic cleaning and low-temperature vacuum drying.

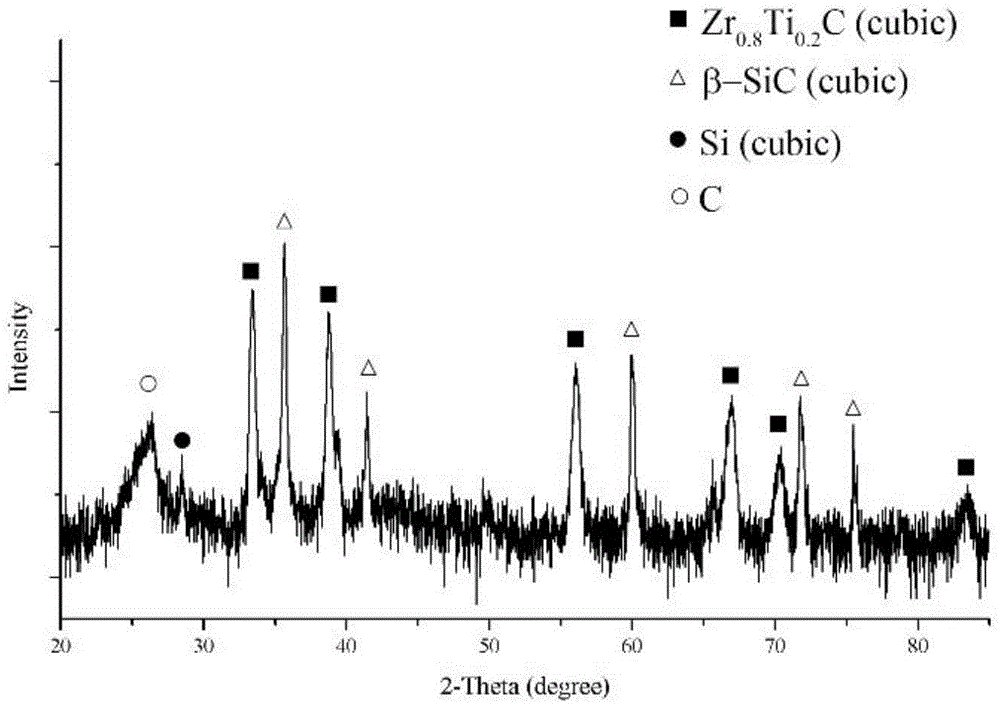

[0050] Put silicon powder, zirconium powder and titanium powder with a purity greater than 99% in the ball mill tank at an atomic ratio of 84%, 12%, and 3%, respectively, and simultaneously add copper powder at an atomic ratio of 1%, and process it through a planetary ball mill A mixed powder is obtained. The ball milling medium is stainless steel, the ball-to-material ratio is 4:1, the milling speed is 150r / min, and the milling t...

Embodiment 2

[0055] Set the density to 0.78g / cm 3 The carbon fiber needle-punched integral felt is placed in a closed furnace cavity, propylene and hydrogen are introduced, and the temperature is kept at 1100°C for 90h, and the pressure in the furnace is 1.7Kpa. The surface of the fibers in the carbon fiber braid is gradually deposited to form pyrolytic carbon by chemical vapor infiltration, and a density of 1.27 g / cm is obtained. 3 –1.36g / cm 3 The C / C composite material is prepared for subsequent steps after ultrasonic cleaning and low-temperature vacuum drying.

[0056] Put silicon powder, zirconium powder and titanium powder with a purity greater than 99% in the atomic ratio of 66%, 22%, and 11%, respectively, in a ball mill tank, and at the same time add iron powder in an atomic ratio of 1%, and process it through a planetary ball mill A mixed powder is obtained. The ball milling medium is stainless steel, the ball-to-material ratio is 8:1, the milling speed is 200r / min, and the mil...

Embodiment 3

[0061] Set the density to 0.32g / cm 3 The chopped carbon fiber laminated needle felt is placed in a closed furnace cavity, propylene and hydrogen are introduced, and the temperature is kept at 1200 ° C for 90 hours, and the pressure in the furnace is 1.8Kpa. The surface of the fibers in the carbon fiber braid is gradually deposited to form pyrolytic carbon by chemical vapor infiltration, and a density of 1.00 g / cm is obtained 3 –1.28g / cm 3 The C / C composite material is prepared for subsequent steps after ultrasonic cleaning and low-temperature vacuum drying.

[0062] Put silicon powder, zirconium powder and titanium powder with a purity greater than 99% in a ball mill tank at an atomic ratio of 77%, 18%, and 4% respectively, and at the same time add aluminum powder at an atomic ratio of 1%, and process it through a planetary ball mill A mixed powder is obtained. The ball milling medium is ZrO 2 , the ball-to-material ratio is 10:1, the milling speed is 300r / min, and the mil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com