Magnetic micro-nano sheet, and preparation method and application thereof

A micro-nano, magnetic technology, applied in the field of magnetic nano, to achieve the effect of broad application prospects, strong magnetic response, and strong microwave absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

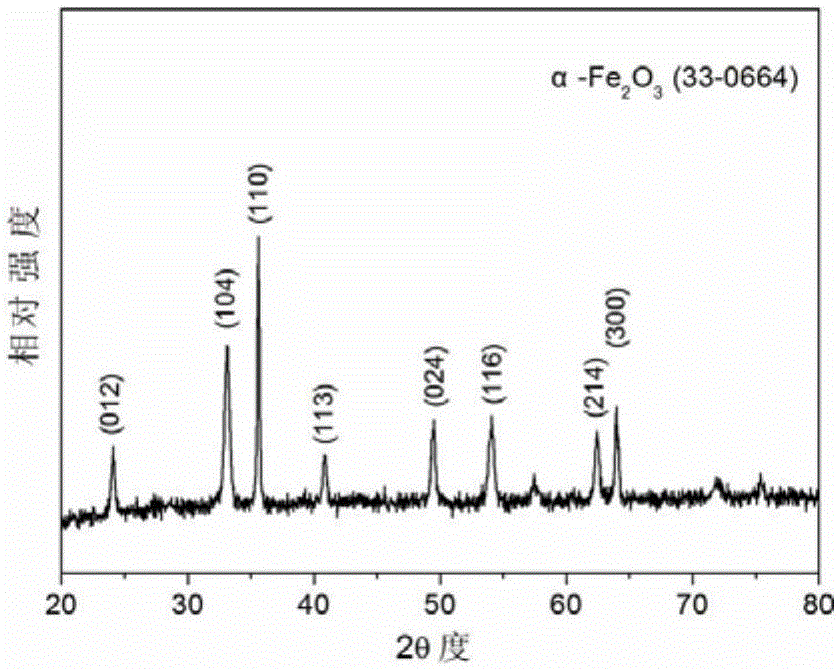

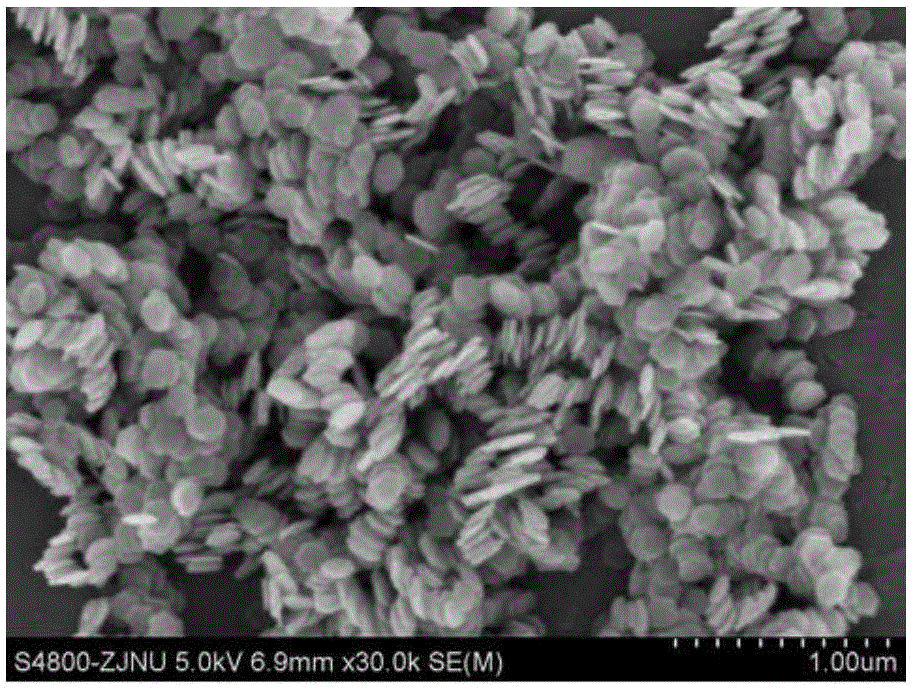

[0032] 4mmolFeCl 3 ·6H 2O, 3.0mL distilled water and 37.0mL absolute ethanol were added to the polytetrafluoroethylene lining, and magnetically stirred for 5min to obtain a transparent solution. Add 40mmol of sodium acetate (the ratio of alkali to metal salt is 10) into the lining and mix and stir for 30min. Finally, put the lining into a stainless steel kettle and react at 180°C for 12 hours, and then wash it by centrifugation after cooling. Dry at 60°C for 6h to obtain the desired monodisperse nanosheets. The resulting product is brick red, and the phase of the product and the morphology observed under the scanning electron microscope are as follows: Figure 1-2 shown. It can be seen that the product is hexagonal α-Fe 2 o 3 The diameter of the nanosheet (which is the diameter of the circumscribed circle of the hexagon) is 121-173 nm, and the thickness is about 10 nm.

[0033] Weigh 10 mg of sample into a 100 ml small beaker, measure 50 mL of 0.02 mmol / L rhodamine B so...

Embodiment 2

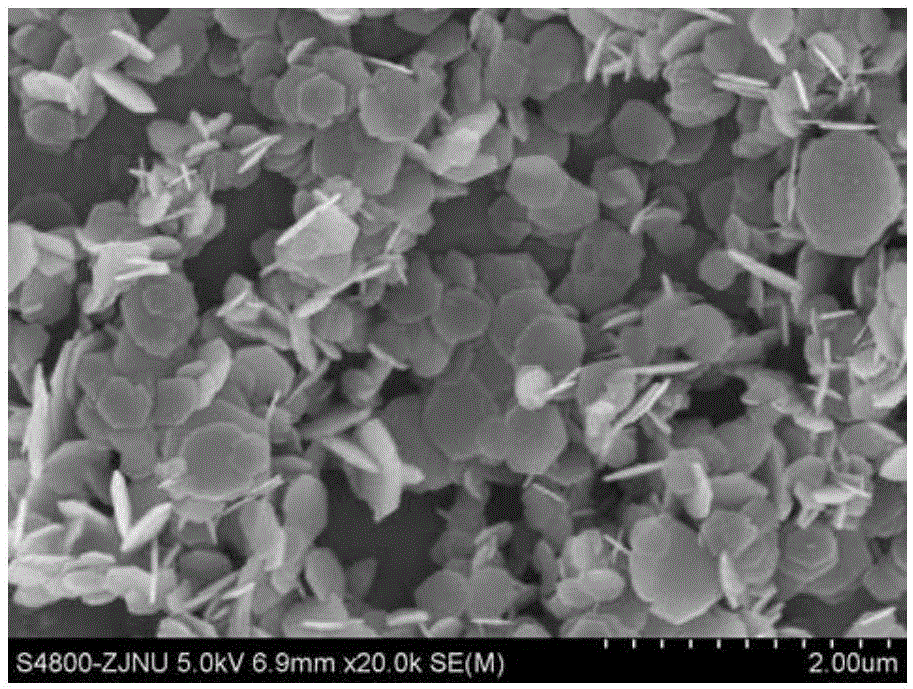

[0035] The procedure is the same as in Example 1, but distilled water is 1.0 mL, and absolute ethanol is 39.0 mL. The resulting product is brick red, and the morphology observed under the scanning electron microscope is as follows: image 3 As shown, it can be seen that the reduction of the amount of water leads to α-Fe 2 o 3 The diameter of the hexagonal nanosheets increases to 355-868nm, and the thickness is about 30nm.

Embodiment 3

[0037] The procedure is the same as in Example 1, but the volume of distilled water is 4.0 mL, and that of absolute ethanol is 36.0 mL. The resulting product is brick red, and the morphology observed under the scanning electron microscope is as follows: Figure 4 As shown, it can be seen that the increase of water amount leads to α-Fe 2 o 3 The diameter of the hexagonal nanosheets is reduced to 83-120 nm, and the thickness is about 15 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com