Continuous welding production method of light H-type steel

A production method and technology for H-beams, applied in the field of deep processing of steel, can solve the problems of low efficiency and output, inability to continuously produce, and high production costs, and achieve the effects of high production efficiency, high utilization rate, and reduced structural weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

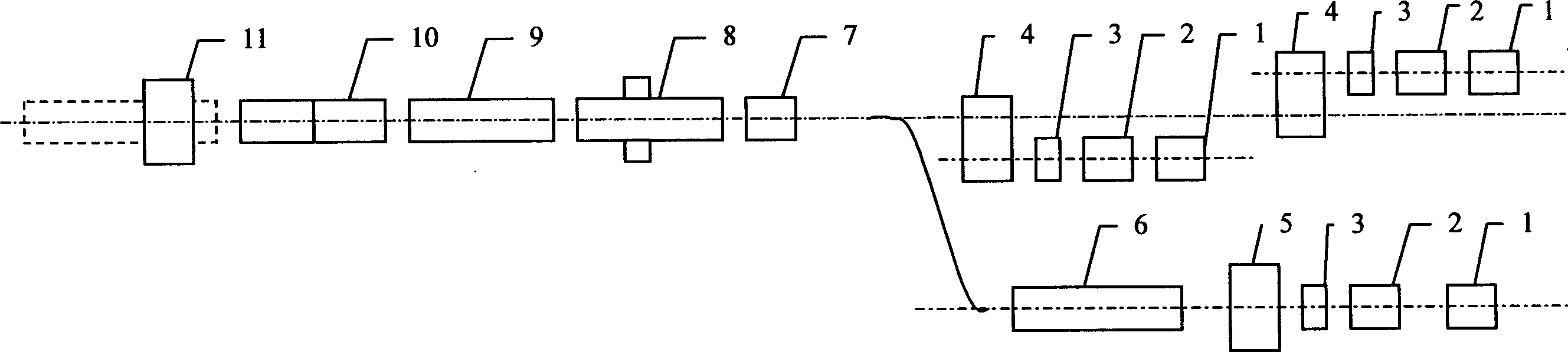

[0033] Adopt the continuous welding production method of light H-shaped steel according to the present invention, according to decoiling, straightening, shear butt welding, loop storage, web pier edge, pre-assembly, high-frequency welding, accelerated cooling, straightening and sizing According to the shearing process, 4 batches of light H-beams were produced. The type of strip steel used, the size of the light H-beam and the cut-to-length length of the final section steel are shown in Table 1. The process parameters to be controlled in the process flow: the pressure of the belly pier, the pressure between the pre-assembled two kinds of strip steel The micro-tension, high-frequency welding parameters, and accelerated cooling rate are listed in Table 2.

[0034] batch number

[0035]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com