Patents

Literature

31results about How to "Solve process cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

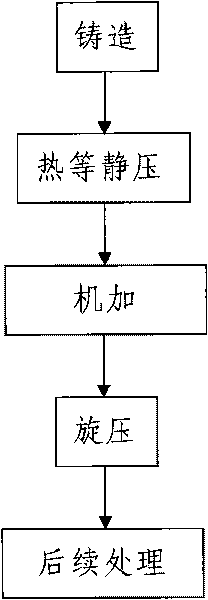

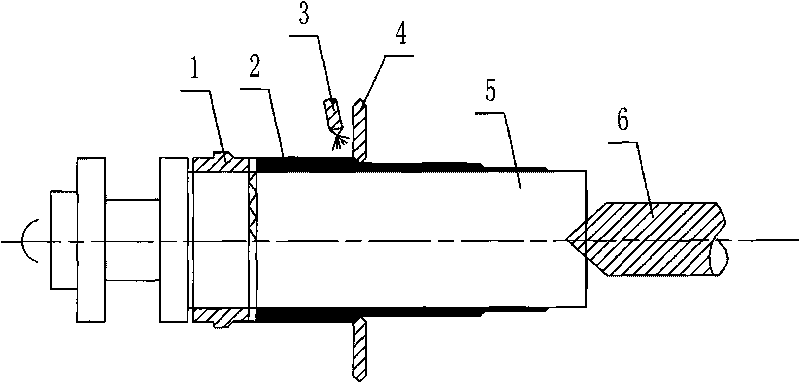

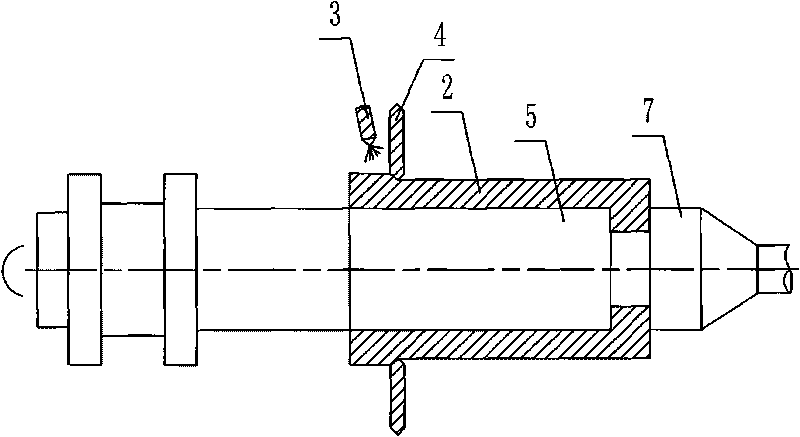

Manufacturing method of large-calibre seamless titanium alloy barrel body

InactiveCN101733641AWide range of sizesEasy to prepareOther manufacturing equipments/toolsTitanium alloyMachining

The invention discloses a manufacturing method of a large-calibre seamless titanium alloy barrel body, which comprises the steps of: 1, casting: casting titanium alloy raw materials into a large-calibre titanium alloy barrel blank by using a vacuum smelting furnace and through a vacuum smelting method; 2, hot isostatic pressing: performing the hot isostatic pressing for the large-bore titanium alloy barrel blank in an inert protective atmosphere by using a hot isostatic pressing device; 3, mechanical machining: processing a chamfer angle for spinning at the head of the large-bore titanium alloy barrel blank after the hot isostatic pressing by using mechanical processing equipment to obtain a spinning barrel blank; 4, spinning: thermally spinning the mechanically processed spinning barrel blank with the total deformation rate not less than 60% for many times by using spinning equipment to obtain a large-bore seamless titanium alloy thin-wall barrel body; and 5, subsequent treatment. The production process has short process flow, high yield, low cost, high utilization rate of materials and easy realization, and the defects of the large-bore seamless titanium alloy barrel body, such as complex process, high cost, low yield and the like of the traditional production process can be effectively solved.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

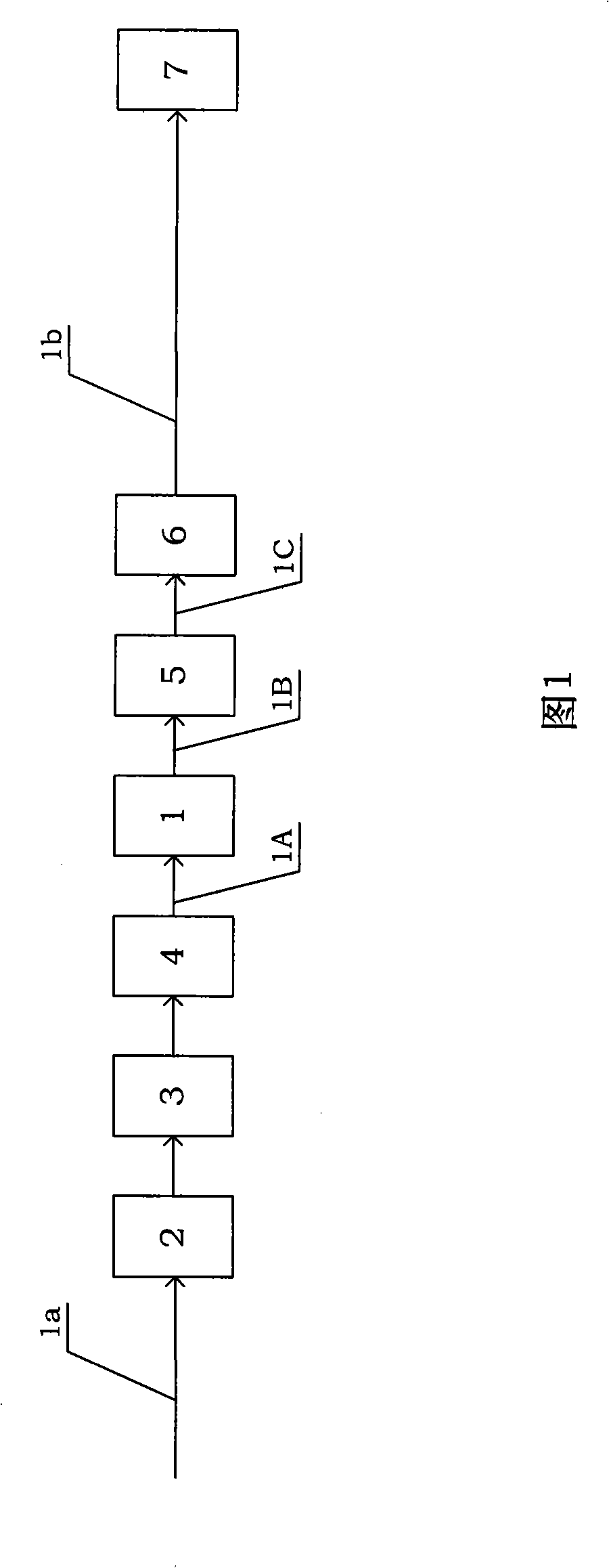

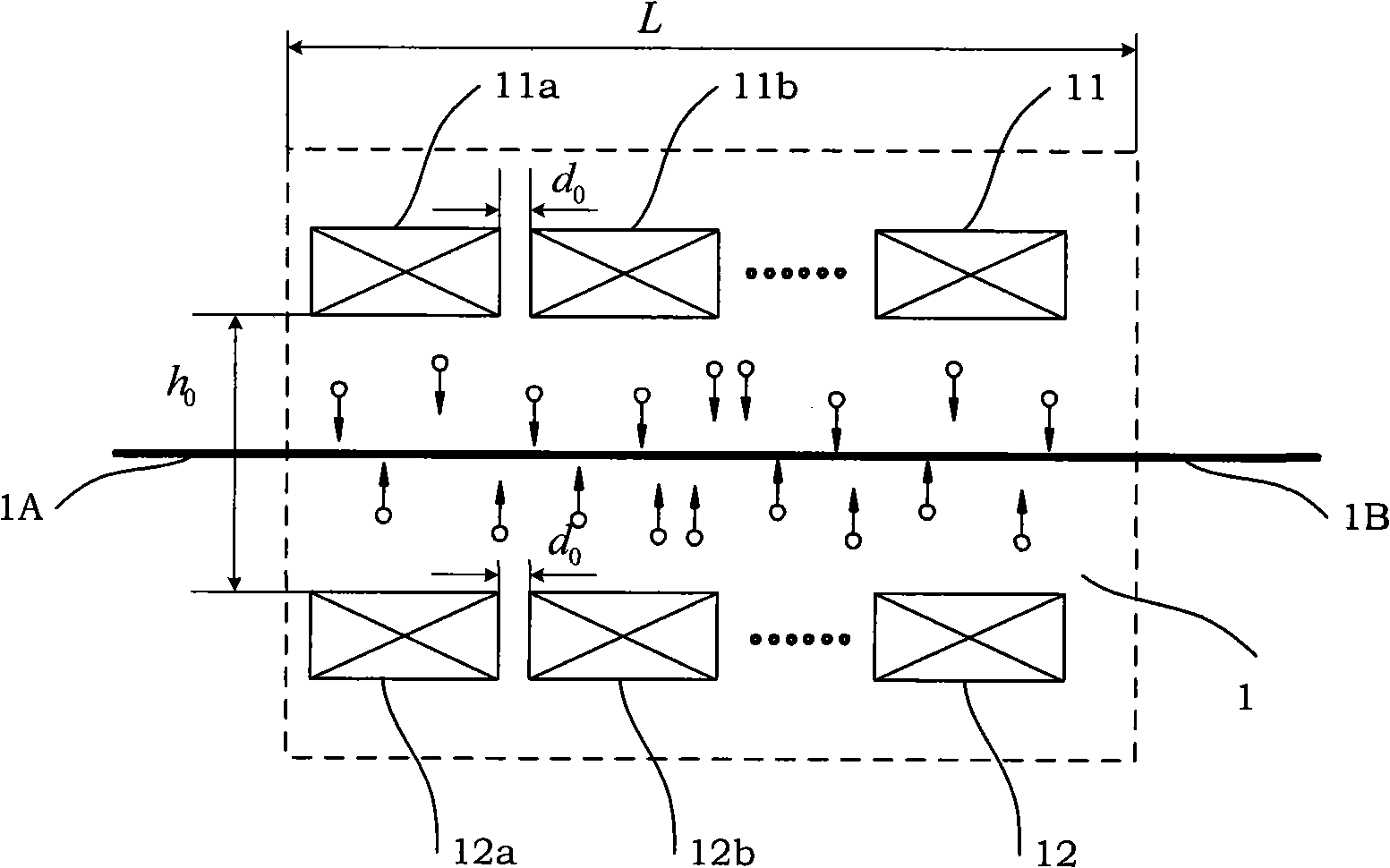

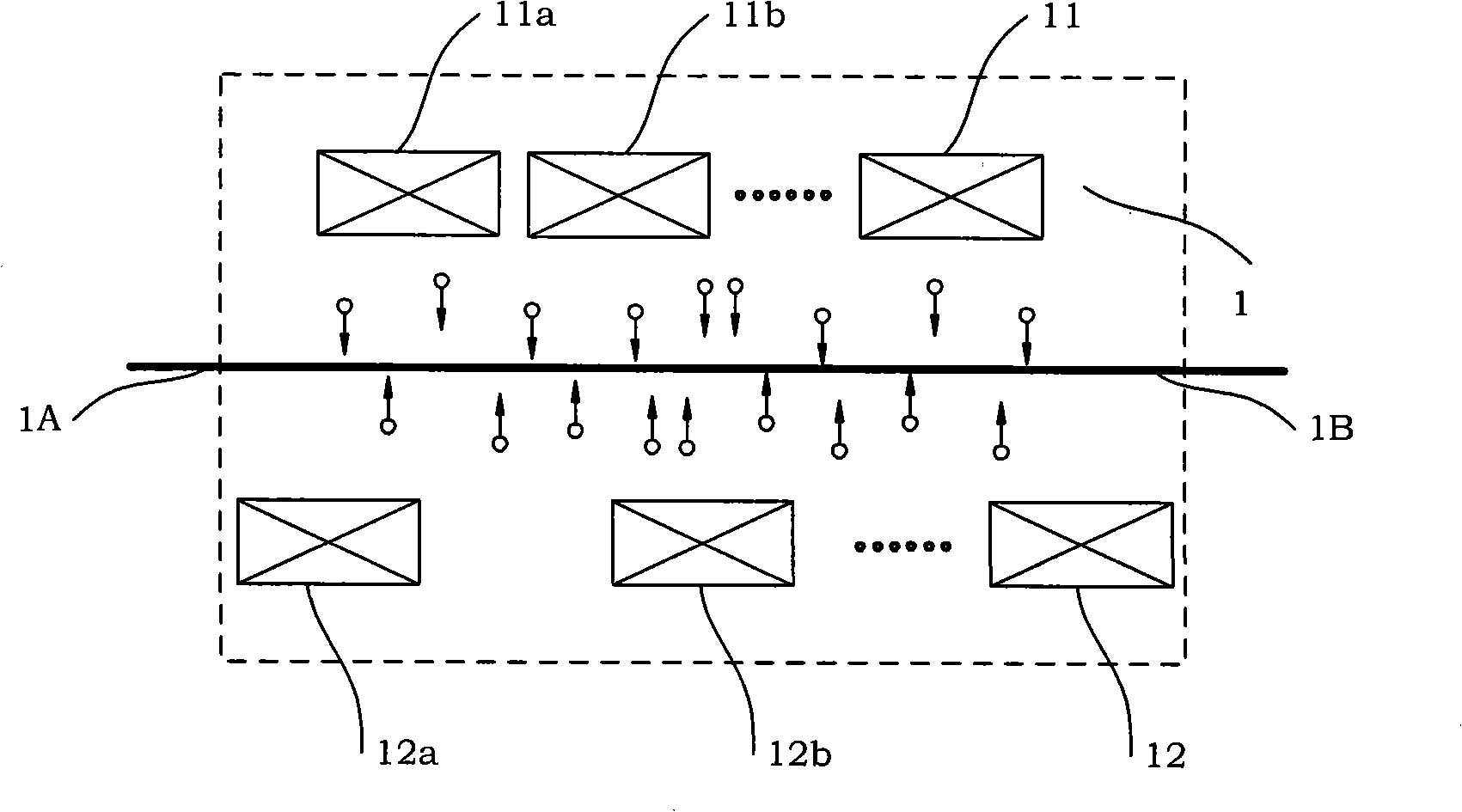

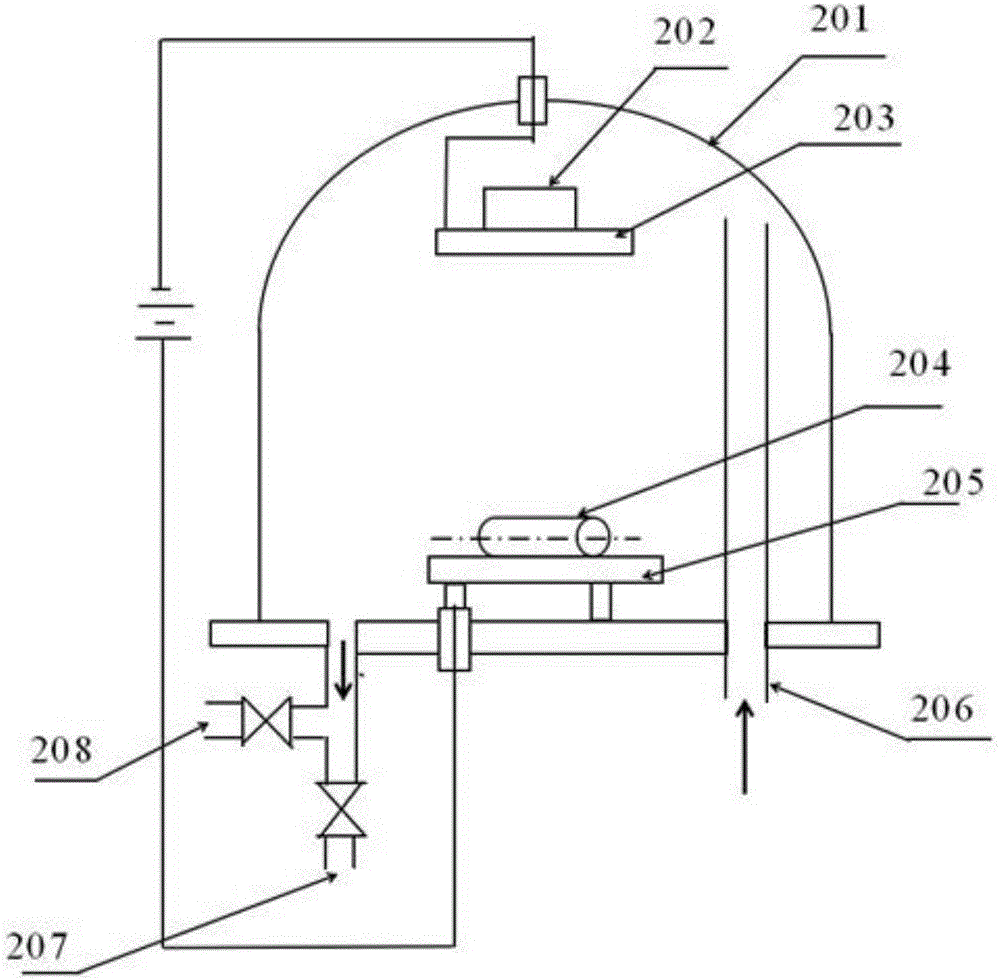

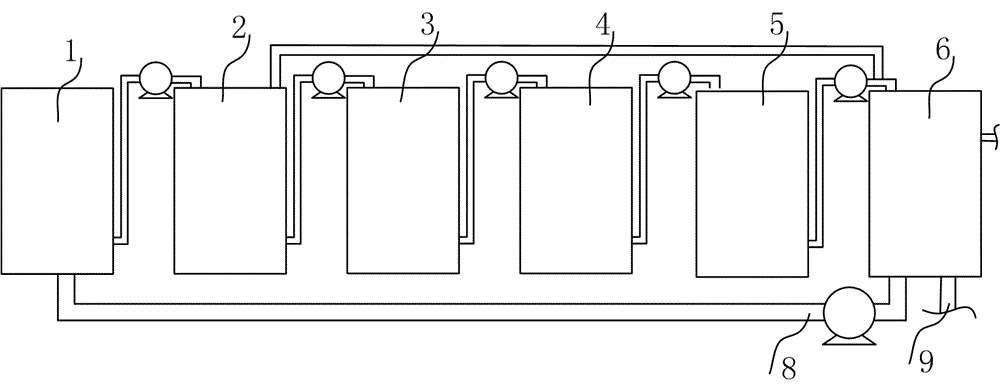

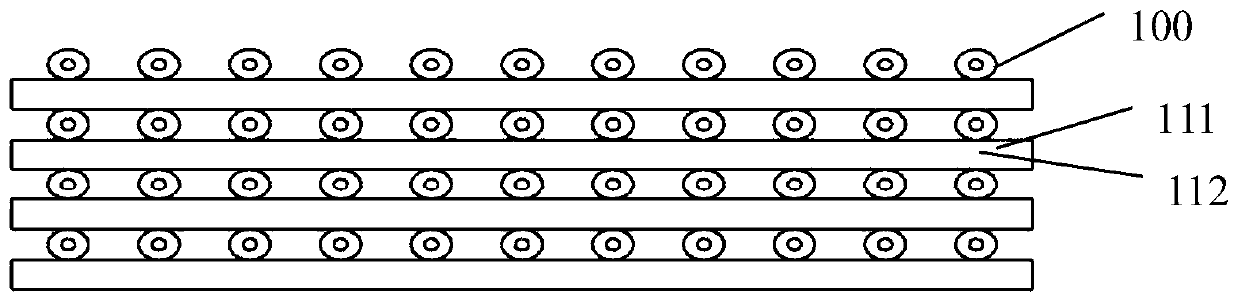

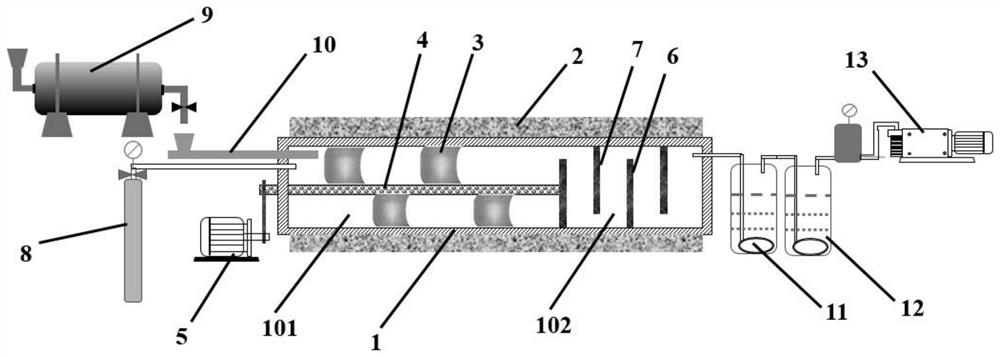

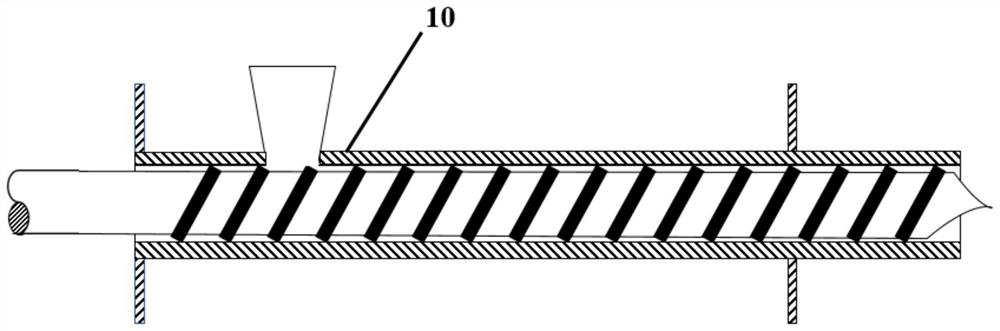

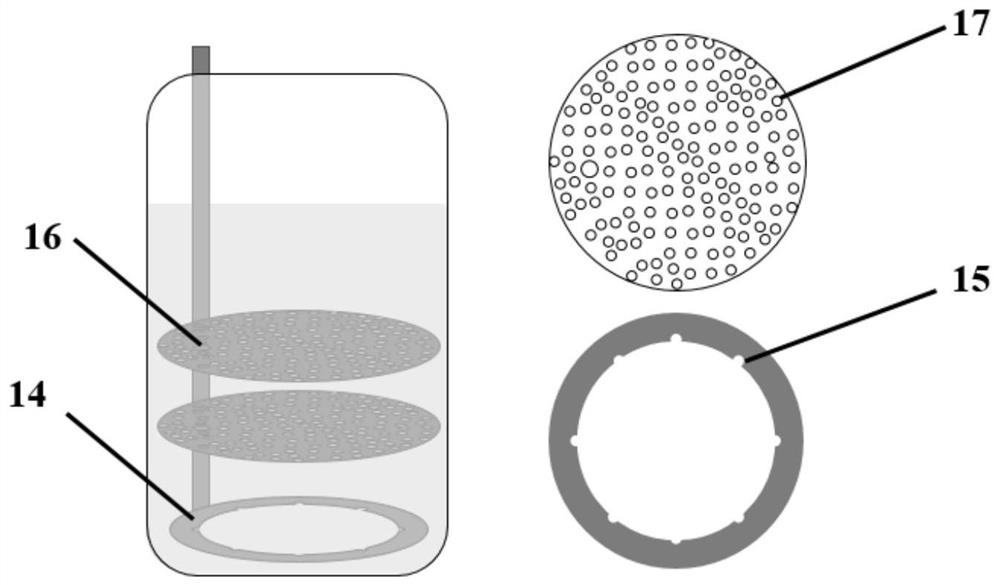

Industrial production system for producing high-silicon strip with magnetron sputtering continuous two-sided codeposition process

InactiveCN101319306ASilicon content adjustmentAdjustable thicknessVacuum evaporation coatingSputtering coatingProduction lineGas phase

The invention discloses an industrialized production system for making a high-silicon steel strip by a process of magnetron sputtering continuous double-sided codeposition. The industrialized production system of a high-silicon silicon plate comprises a welding machine (3), a preheating chamber (4), a magnetron sputtering chamber (1), a diffusion chamber (5), a cooling chamber (6), and a coiler (7), which are sequentially arranged on a production line starting from the deliverty of the low-silicon silicon plate to the production system by an unwinding coiler (2) to the finish of the production of high-silicon silicon plate. The industrialized production system for making the silicon material by the process of the continuous double-sided codeposition, driven by the unwinding coiler (2), is capable of performing deposition on a the low-silicon silicon plate with a thickness of less than 0.35mm with silicon content of between 5 and 8 weight percent to by means of symmetrically disposing a plurality of cathode targets in the magnetron sputtering chamber, thereby achieving the aim of continuous deposition of silicon material with low energy consumption and high production efficiency. The industrialized production system solves the defect that the silicon plate of the commercialized Fe-6.5 weight percentage Si can only be produced by adopting a method of chemical gas-phase deposition.

Owner:BEIHANG UNIV

Production method of electric contact point

InactiveCN101320642ASolve productivityAddress process complexityElectric switchesElectricityManufacturing technology

The invention discloses a manufacturing method of an electric contact; the electric contact manufactured by the method is made by electroplating the contact material on the outer surface needing to contact power transmission of the shaped conductive substrate; the outermost clad layer of the contact material is added with putty powder in the plating solutions of silver plating to lead the putty powder to deposit the obtained silver tin oxide layer together with the metallic silver. The invention relates to the technical field of manufacturing the electric contact element; the electric contact manufactured in the invention is able to solve the problem of the much production equipment, complicated technique and high producing cost in the existed technology.

Owner:LIUZHOU CITY SEMICON MATERIAL FACTORY

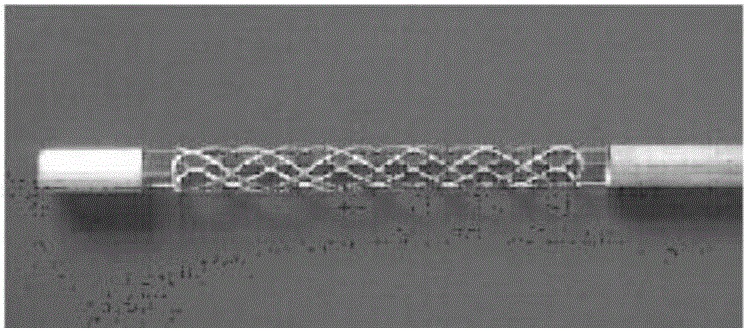

Manufacturing method for manufacturing magnesium alloy vascular stent

ActiveCN106620837AAddress process complexitySolve process costVacuum evaporation coatingSputtering coatingSputteringPercent Diameter Stenosis

The invention provides a manufacturing method for manufacturing a magnesium alloy vascular stent, and the manufacturing method adopts a 3D (three dimensional) printing technology to solve the technical problems that an existing magnesium alloy stent is complex in process and high in cost during manufacturing. The manufacturing method comprises the following steps: adopting the 3D printing technology to manufacture a prefab of the magnesium alloy vascular stent; adopting magnetron sputtering for sputtering a magnesium alloy target to the surface of the prefab; soaking the prefab sputtered with the magnesium alloy target into an alcohol solution or an aqueous solution to dissolve the prefab, thereby obtaining the magnesium alloy vascular stent. The manufacturing method adopted by the invention simplifies the process, reduces the cost and has a wide application prospect. And a novel tunicamycin drug coating is adopted, so that formation of postoperative restenosis is reduced, and the curative effect and safety are improved.

Owner:杨水祥

Method for purifying low-grade natural gypsum or gypsum tailings by recrystallization

InactiveCN104528798AAddress process complexitySolve process costCalcium/strontium/barium sulfatesSolubilityImpurity

The invention relates to the field of preparation of high purity gypsum and particularly relates to a method for purifying low-grade natural gypsum or gypsum tailings by recrystallization. The method provided by the invention mainly comprises the following six steps: crushing; screening; dissolving; crystallizing; washing; and drying. The method specifically comprises the following steps: crushing and screening the low-grade natural gypsum or gypsum tailings; then, adding the low-grade natural gypsum or gypsum tailings into an acid at special solubility; heating to a certain temperature till the low-grade natural gypsum or gypsum tailings is / are fully dissolved; carrying out solid-liquid separation to remove undissolved solid phase impurities while the solution is hot; cooling, recrystallizing a liquid phase at a relatively low temperature and carrying out solid-liquid separation; and washing and drying a filter cake to obtain the high purity gypsum. The liquid phase in the dissolving and crystallizing processes can be repeatedly used. According to the method provided by the invention, proper raw material granularity, solid liquid ratio, temperature and acid concentration are selected and the raw materials are dissolved and crystallized for a certain time to prepare gypsum with relatively high purity, so that the grade or performance of the gypsum is remarkably improved.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

Method for producing electrolytic manganese from manganese carbonate ore with low manganese content and high iron content

The invention discloses a method for producing electrolytic manganese from manganese carbonate ore with low manganese content and high iron content. According to the method, the manganese carbonate ore with low manganese content and high iron content is mixed with manganese dioxide ore, and a direct leaching method is adopted. According to the technical scheme, the manganese carbonate ore is directly acid-leached to prepare a manganese sulfate solution, then the solution is prepared into electrolyte by a series of processes of neutralization, purification and filtering, and the electrolyte can enter an electrolytic bath for electrolysis by adding additives such as selenium dioxide, ammonium sulfite and the like. The method disclosed by the invention has the characteristics that a series of problems that reduction process equipment utilizing manganese dioxide ore to produce electrolytic manganese is large in investment, complex in process and high in cost, has serious production conditions and can not meet the requirements on environmental protection and the like for a long time are solved, and a new path for producing the electrolytic manganese from the manganese dioxide ore is provided; simultaneously, a new path for developing and utilizing the manganese carbonate ore with low manganese content and high iron content is also provided, so that the wastes can become valuables and national resources are fully utilized.

Owner:桂林翔云锰业有限责任公司

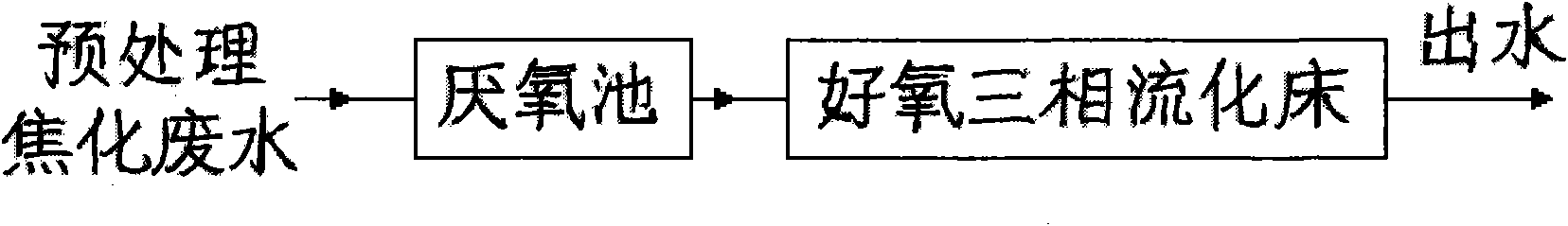

Method for biochemically treating coking wastewater

ActiveCN101913728ANo reflow requiredSolve processingTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentVolatile phenolsEmission standard

The invention discloses a method for biochemically treating coking wastewater. The method comprises the following steps of: pretreating coking wastewater; feeding pretreated coking wastewater into an anaerobic tank for anaerobic treatment; and feeding the treated wastewater into an aerobic three-phase fluidized bed for anaerobic treatment, wherein the pH of the anaerobic tank is between 6.0 and 7.5; the hydraulic retention time is between 8 and 30 hours; the pH of the aerobic three-phase fluidized bed is between 7.5 and 8.5; the hydraulic retention time is between 8 and 24 hours; the dissolved oxygen content is between 2 and 4mg / L; and effluent COD, ammonia nitrogen, volatile phenol and cyanide meet the steel industrial water pollutant effluent standard (GB13456-92) and the primary standard of the integrated wastewater effluent standard (GB 8978-1996). The method can effectively solve the problems of bad treatment effect, large amount of sludge, complicated process, high cost and the like caused by biochemically treating the coking wastewater by ammonia nitrogen and has the advantages of simple operation, low cost, economic feasibility, contribution to popularization, and capability of effectively improving and solving the problem of environment pollution caused by the coking wastewater.

Owner:南京洁水科技有限公司 +1

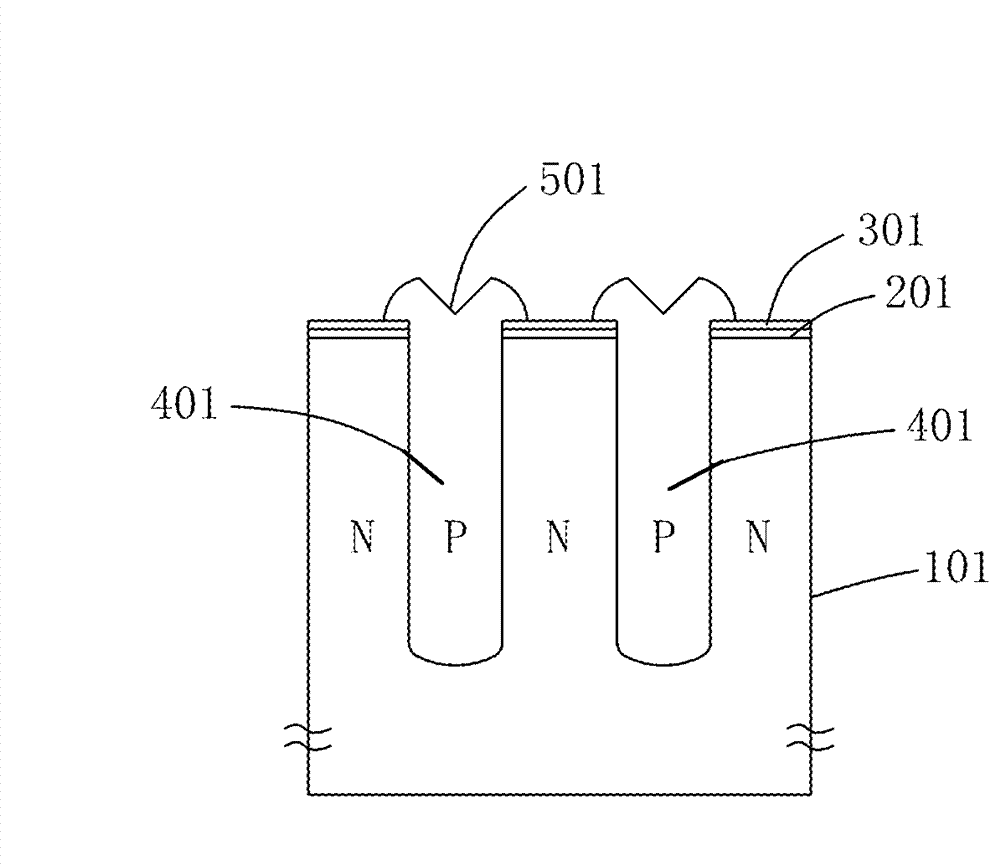

Forming method of semiconductor structure and forming method of transistor

InactiveCN103377942ASimple processEasy to operateSemiconductor/solid-state device manufacturingElectrical conductorNanowire

The invention provides a forming method of a semiconductor structure and a forming method of a transistor. The forming method of the semiconductor structure comprises the steps that a semiconductor substrate is provided, the semiconductor substrate is made of an insulator upper semiconductor comprising a substrate, an insulation layer and a semiconductor layer; a hard mask layer is formed on the surface of the semiconductor substrate; part of the hard mask layer is removed, the rest of the hard mask layer serves as masks, forms a plurality of openings inside the semiconductor layer, and the surface of the insulation layer is exposed out; the side walls of the openings are etched by adopting the crystal orientation anisotropism wet process, and double-layer discrete nanowires are formed; then, the rest of the hard mask layer is removed, the insulation layer between the nanowires and the substrate is removed, and the double-layer discrete nanowires are suspended above the substrate; after the rest of the hard mask layer and the insulation layer are removed, thermal annealing is conducted on the nanowires so that the cross section of each nanowire becomes round. The forming method of the semiconductor structure is low in production cost, simple in process, and suitable for large-scale production.

Owner:SEMICON MFG INT (SHANGHAI) CORP

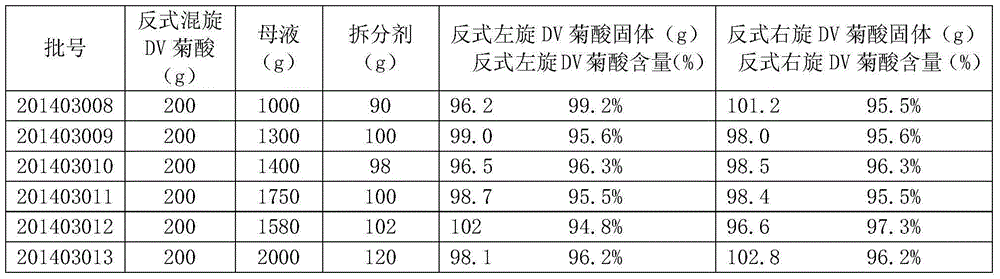

Preparation method for 3-(2,2-dichloroethyenyl)-2,2-dimethylcyclopropanecarboxylic acid

ActiveCN105272848ASolve productivityAddress process complexityPreparation from carboxylic acid saltsOrganic compound preparationChrysanthemic acidDouble salt

The invention provides a preparation method for 3-(2,2-dichloroethyenyl)-2,2-dimethylcyclopropanecarboxylic acid. The preparation method comprises the following steps: adding 200 g of trans-(+ / -)-DV-chrysanthemic acid into 1000 to 2000 g of mother liquor under stirring and adjusting a pH value to 6.5 to 8.2 by using alkali so as to produce a trans-(+ / -)-DV-chrysanthemate solution; dissolving 90 to 110 g of a resolving agent in water under stirring and adjusting a pH value to 2 to 5 by using acid so as to obtain an aqueous solution of the resolving agent; adding the aqueous solution of the resolving agent into the trans-(+ / -)-DV-chrysanthemate solution drop by drop within 1 to 3 h under stirring to produce a solution including solid double salt; adding 200 to 400 g of a separating agent into the solution including the solid double salt under stirring and carrying out stirring to separate a solid double salt particle and a water phase; and adding acid under stirring to adjust the pH value of separated water phase liquid to 2 to 4 so as to form a solid and an aqueous solution, wherein the solid is 3-(2,2-dichloroethyenyl)-2,2-dimethylcyclopropanecarboxylic acid. The preparation method provided by the invention overcomes the problems of long production flow, complex process and high cost in conventional resolution methods for preparation of 3-(2,2-dichloroethyenyl)-2,2-dimethylcyclopropanecarboxylic acid.

Owner:正泓(盘锦)精细化工科技有限公司

Preparation method and application of polyamino vinyl silicone oil

InactiveCN112961355AGood flexibilityHigh viscosityLight resistant fibresGrip property fibresDisiloxanePolymer science

The invention belongs to the technical field of organic silicon material preparation, and particularly relates to a preparation method and application of polyamino vinyl silicone oil. The preparation method comprises the following steps: 1) under the condition of inert gas, adding a basic catalyst and a siloxane ring body, heating while stirring, reacting for a period of time, then adding a polyamino silane coupling agent and tetramethyl divinyl disiloxane, and continuously reacting for a period of time; and 2) performing heating and continuously performing reacting for a period of time to obtain a semitransparent viscous liquid. The invention solves the problems that in the prior art, an amino silicon oil preparation method is numerous in operation steps and high in manufacturing cost, and softness and yellowing resistance cannot be achieved at the same time.

Owner:山东特龙谱新材料有限公司

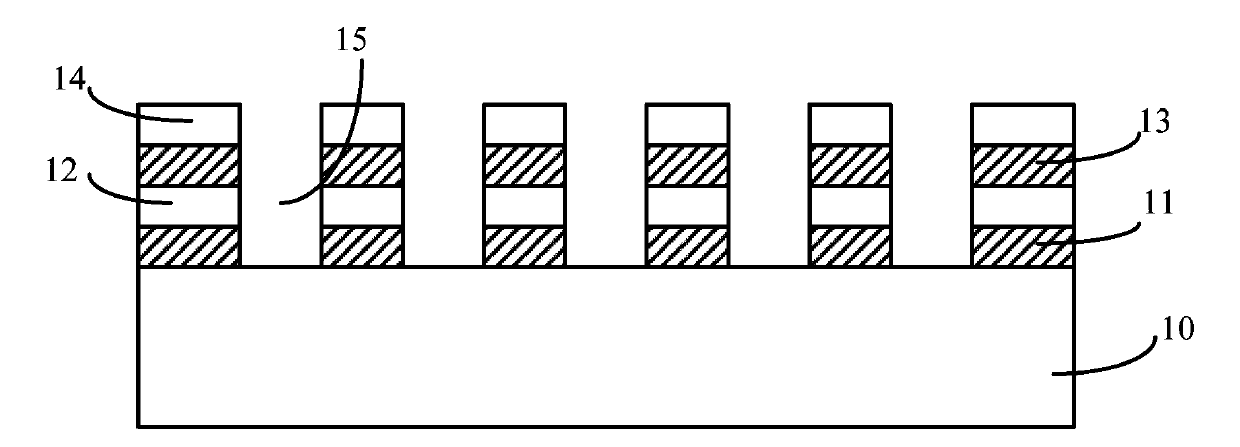

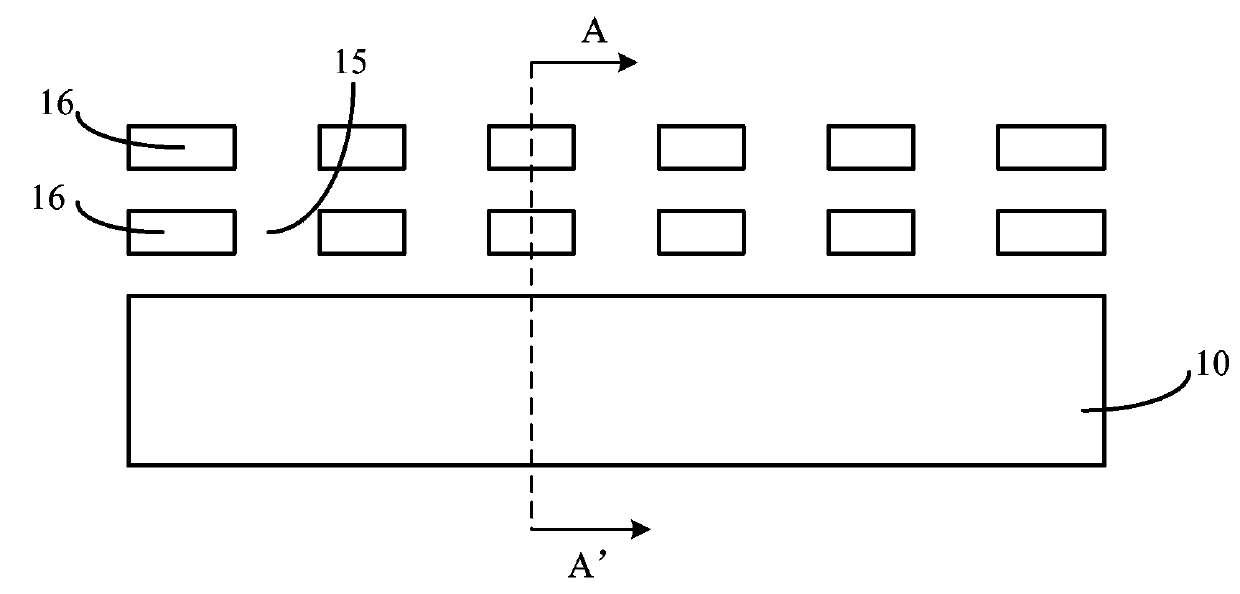

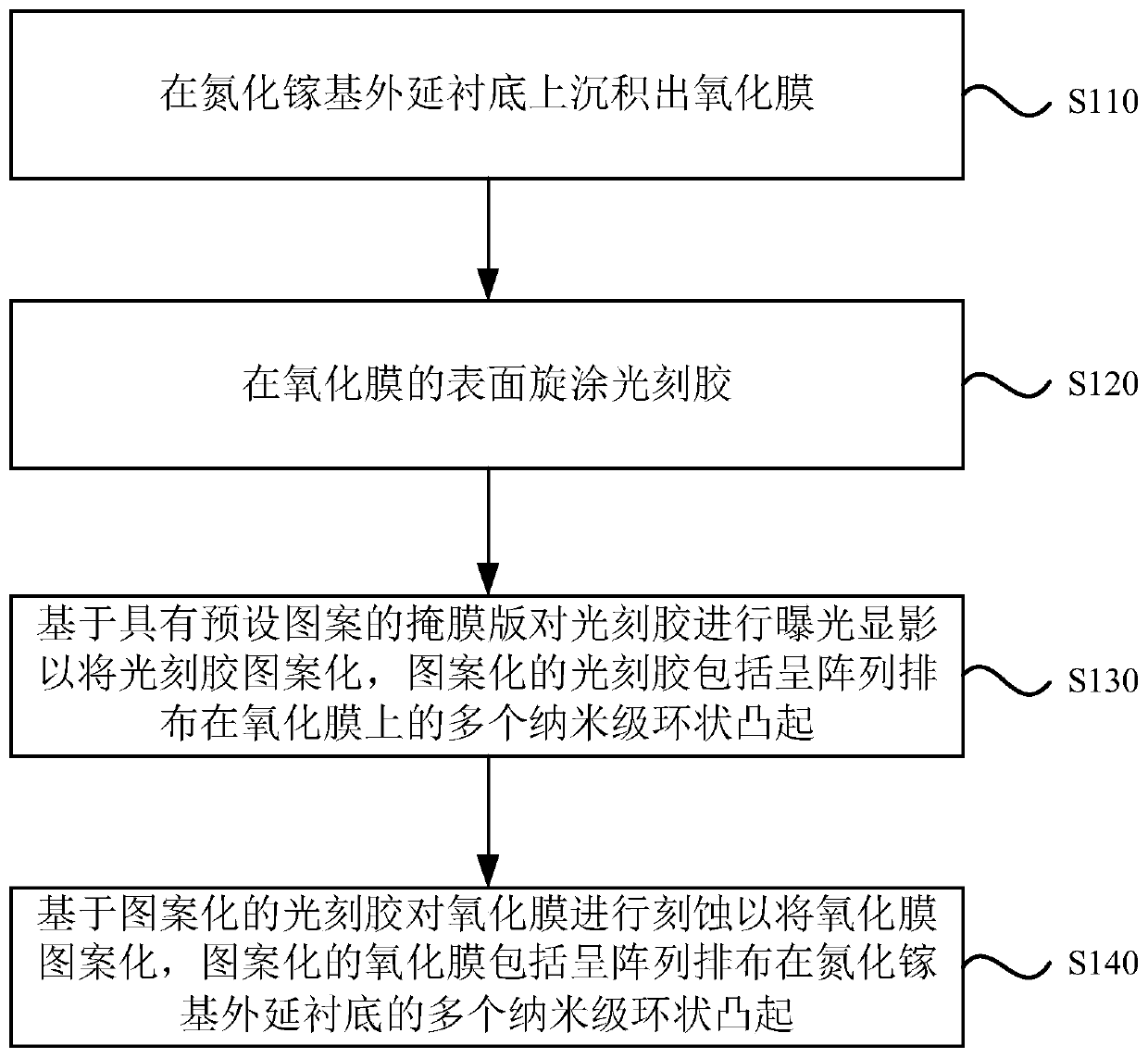

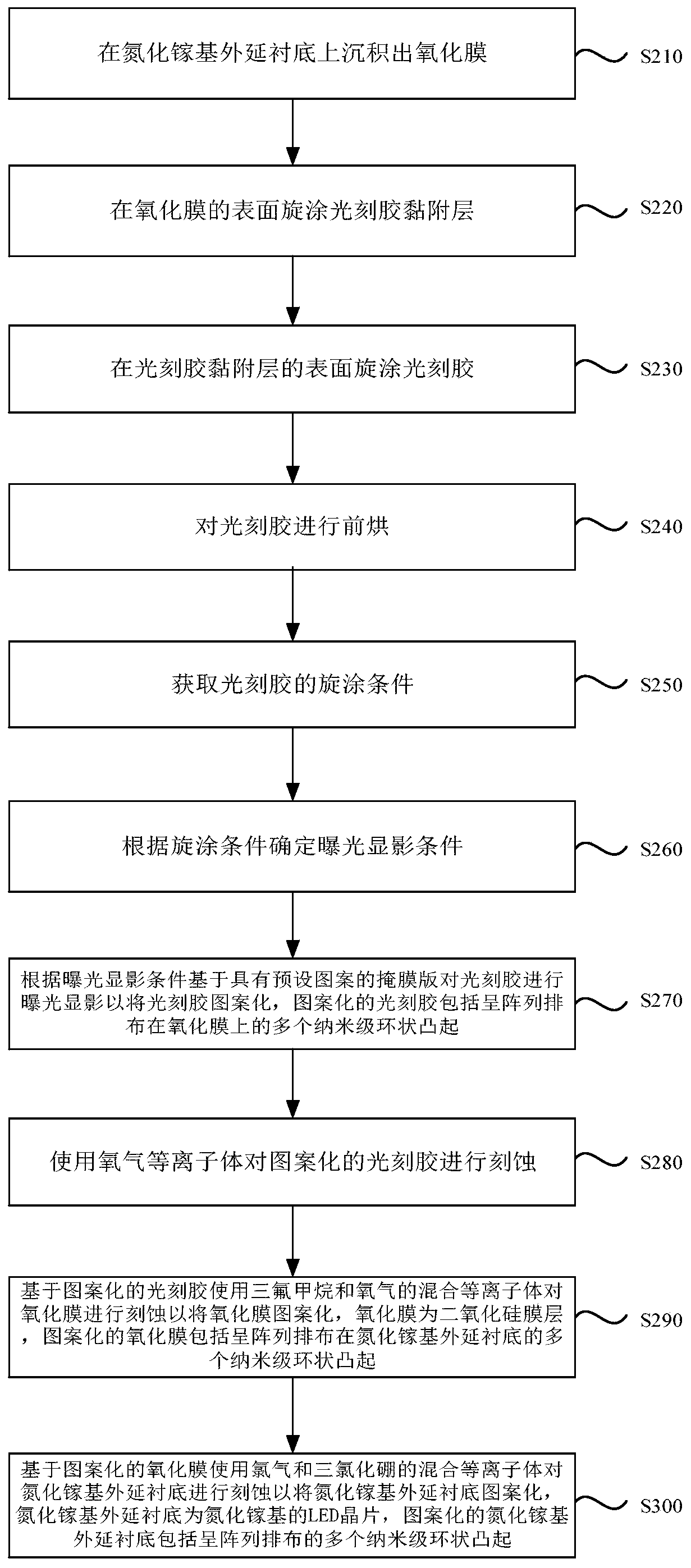

Preparation method of nanoring

ActiveCN111453693AAddress process complexitySolve process costFinal product manufactureDecorative surface effectsFilm baseGallium nitride

The embodiment of the invention discloses a preparation method of a nanoring. The method comprises the following steps: depositing an oxide film on a gallium nitride-based epitaxial substrate; spin-coating photoresist on the surface of the oxide film; carrying out exposure and development on the photoresist based on a mask plate with a preset pattern so as to pattern the photoresist, wherein the patterned photoresist comprises a plurality of nanoscale annular bulges arranged on the oxide film in an array manner; and etching the oxide film based on the patterned photoresist so as to pattern theoxide film, wherein the patterned oxide film comprises a plurality of nanoscale annular bulges which are arranged on the gallium nitride-based epitaxial substrate in an array manner. The embodiment of the invention realizes simple and low-cost preparation of the GaN-based nanoring.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

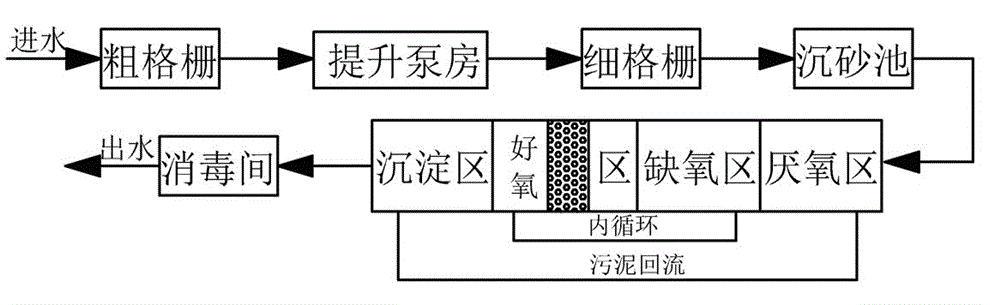

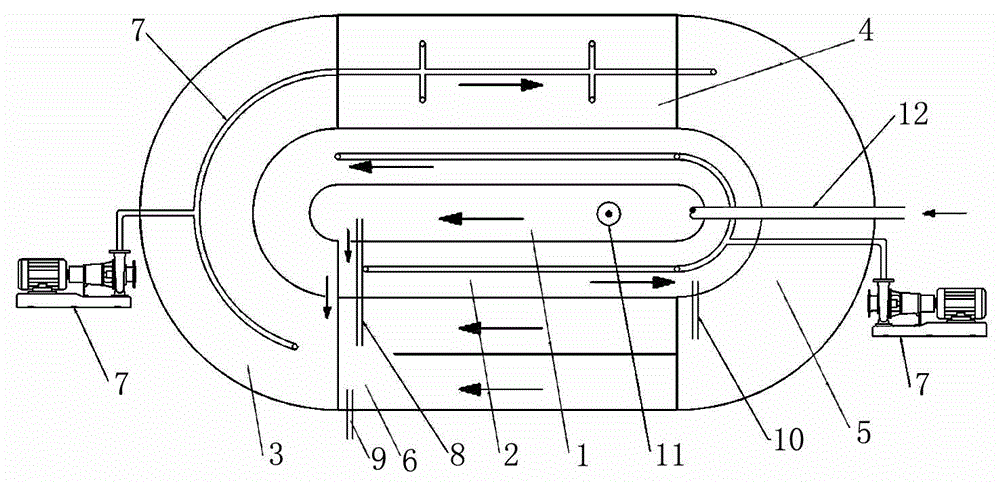

Process and device for treating domestic sewage in high and cold areas

InactiveCN105060481ASufficient carbon sourceInhibit swellingTreatment with aerobic and anaerobic processesSmall footprintTherapeutic effect

The invention discloses a process for treating domestic sewage in high and cold areas and discloses a device of the process. The process comprises the following steps: (1) sewage continuously flows into an anaerobic zone in an oxidation ditch and sequentially flows through an anoxic zone, an aerobic zone and a settling zone to be discharged, wherein a filler zone of a culture is arranged in the aerobic zone and the flow rate of sewage in the oxidation ditch is less than 0.15 m / s; aeration is carried out on sewage in the anoxic zone, the aerobic zone and the filler zone; and (2) sewage at the tail end of the aerobic zone returns to the anoxic zone; sewage in the settling zone partially returns to the anaerobic zone and the rest of sludge is discharged. The process and device disclosed by the invention are applicable to sewage treatment in high and cold areas and have the advantages of being simple in water treatment process, low in treatment cost, low in energy consumption, small in occupied area, excellent in treatment effect and the like.

Owner:四川蓉加川大环保工程咨询设计有限公司

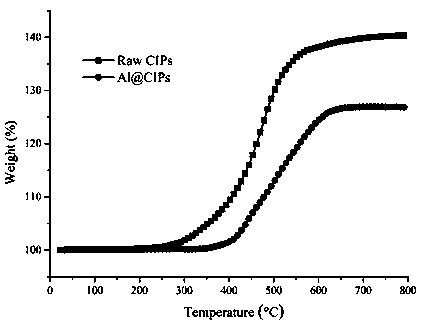

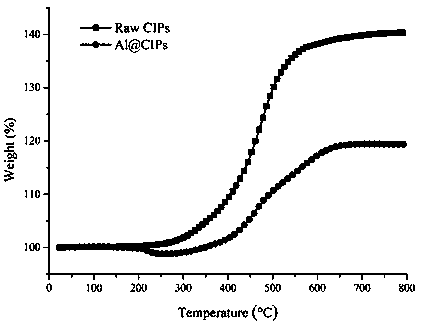

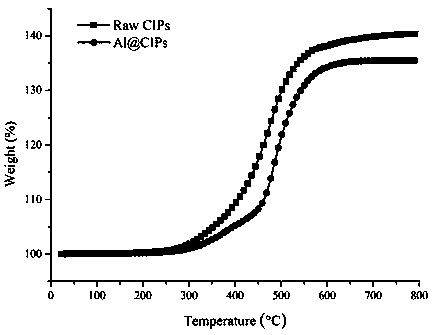

Antioxidant absorbent and preparation method thereof

ActiveCN110814336ACoated evenlyResistance to long-term high-temperature oxidation problemsTransportation and packagingMetal-working apparatusIron powderPhysical chemistry

The invention discloses an antioxidant absorbent and a preparation method thereof. 85-97 wt.% of carbonyl iron powder with an average particle size of 1-6 [mu]m and 15-3 wt.% of aluminum powder with an average particle size of 20-80 nm are weighed according to a mass fraction to be mixed to obtain carbonyl iron / aluminum mixed powder, and then the carbonyl iron / aluminum mixed powder is subjected toball milling at a speed of 100-250 rpm for 4-8 hours in an argon sealing atmosphere; the mass ratio of the spherical materials is 5-15: 1, so that aluminum powder is uniformly attached to the surfaceof the carbonyl iron powder to prepare carbonyl iron / aluminum mixed powder with an iron / aluminum alloying layer; and then washing and drying are performed with an organic solution, ball milling is carried out at a speed of 250-400 rpm for 8-12 hours, the mass ratio of the ball to the material is 15-25: 1, flaky carbonyl iron / aluminum mixed powder is obtained, the thickness of the flaky carbonyl iron / aluminum mixed powder is less than 1 [mu]m, and then washing, drying and sieving are carried out to obtain the antioxidant absorbent. The problem of low oxidation resistance of existing carbonyl iron powder is solved.

Owner:XIAN AERONAUTICAL UNIV

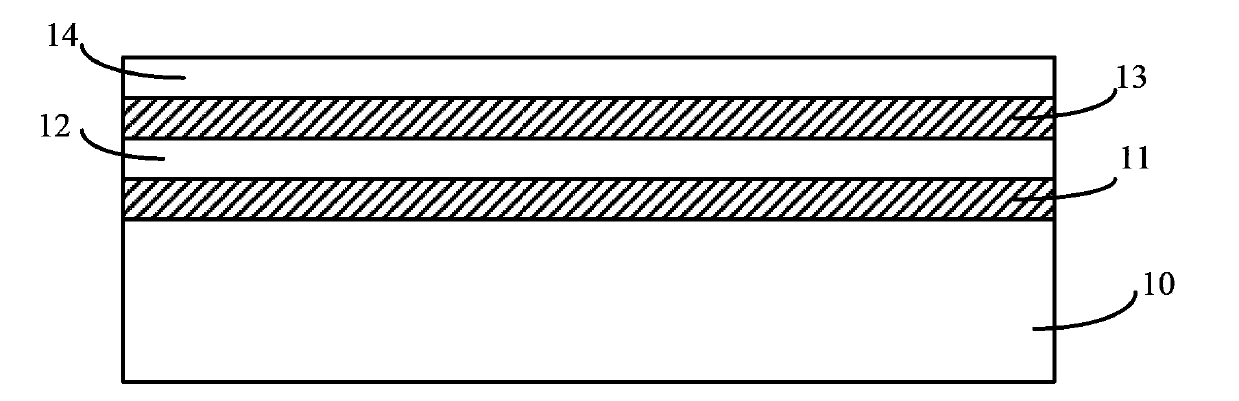

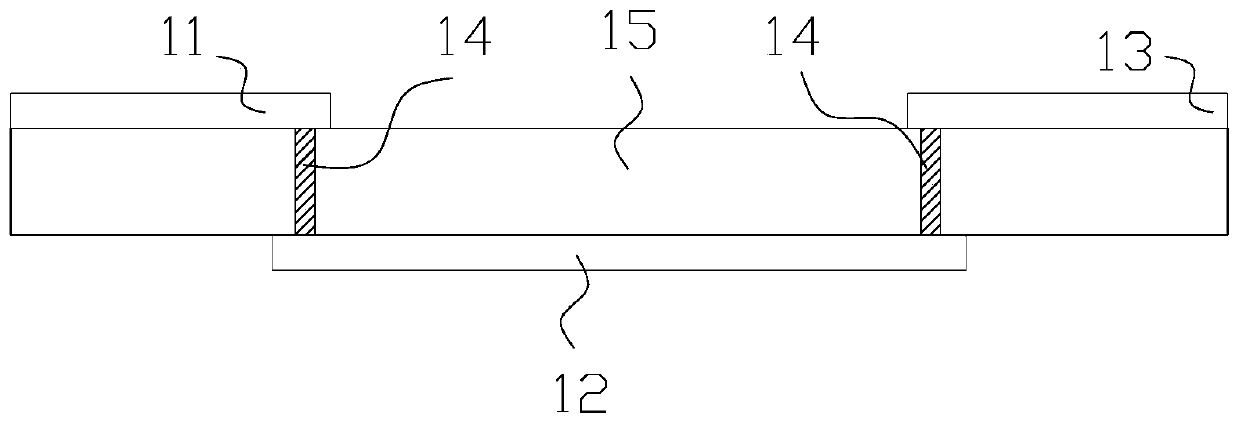

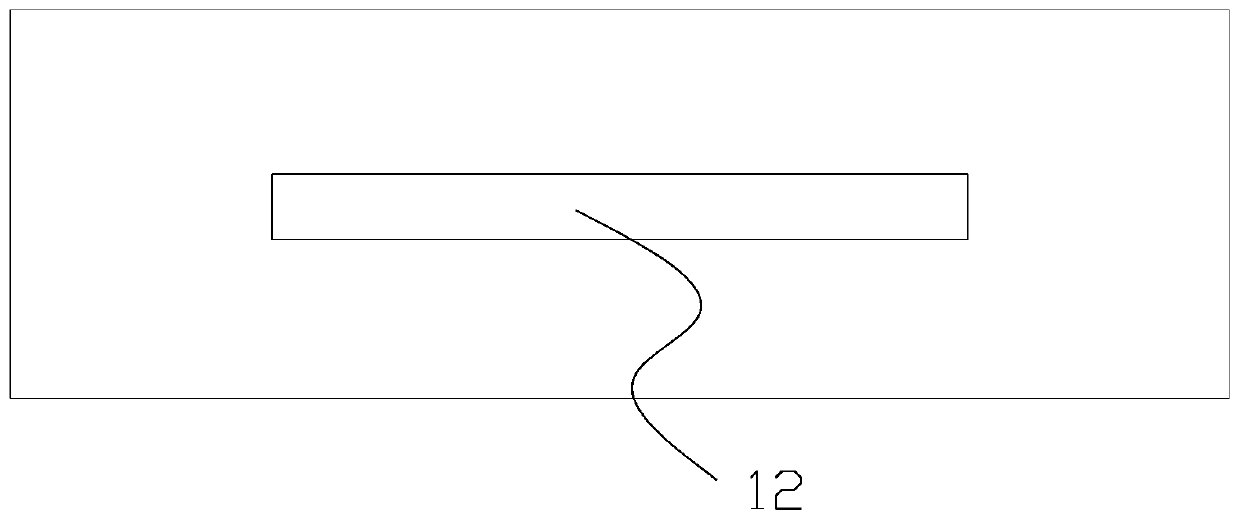

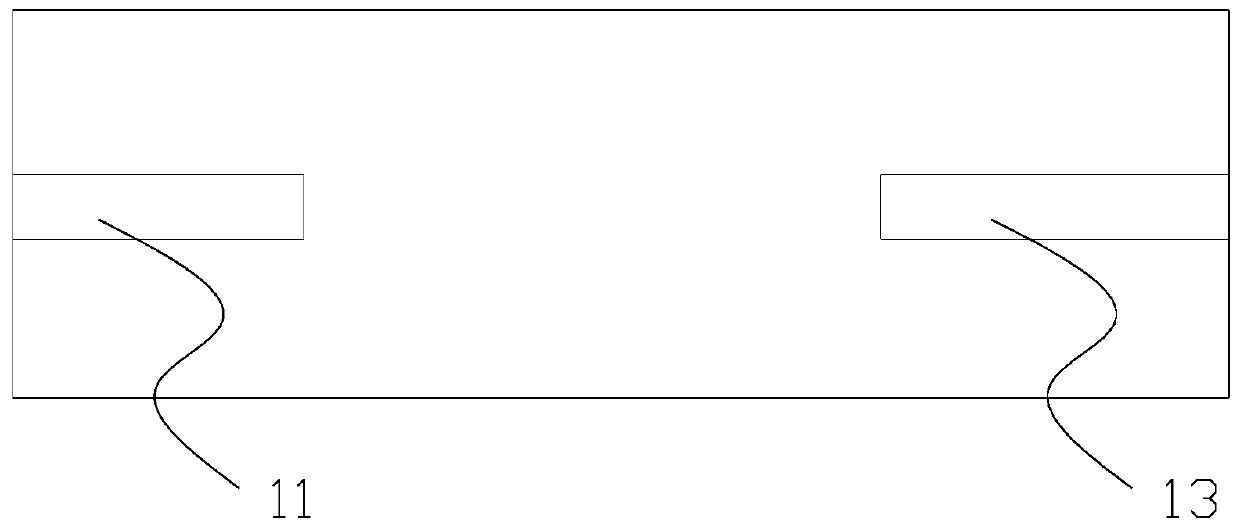

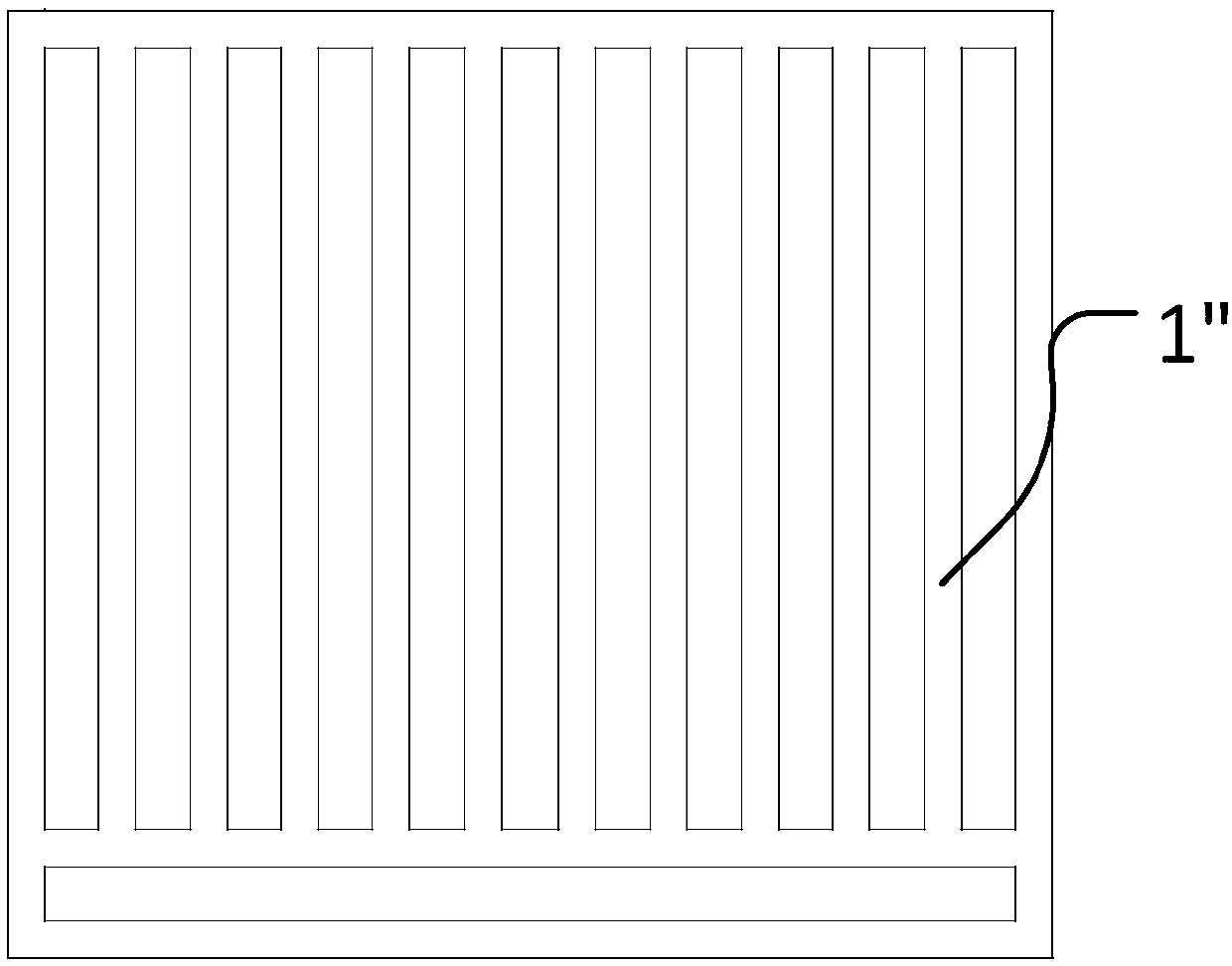

Microstrip transmission device and preparation method

PendingCN111029699AImprove mechanical propertiesSolve the phenomenon of electromigrationSemiconductor/solid-state device detailsSolid-state devicesMaterials scienceElectromigration

The invention discloses a microstrip transmission device and a preparation method, which relate to an electronic device, and particularly design a microstrip transmission line. The microstrip transmission device comprises a substrate and a microstrip line arranged on the surface of the substrate, and is characterized in that the substrate is a glass substrate, a column of metallized through holespenetrating through the substrate is formed in each of two sides of the microstrip transmission line along the trend of the microstrip transmission line, and the metallized through holes are used as shielding holes. The high-frequency signal shielding hole is made of photolithographic glass, and compared with a TSV technology, an insulating layer does not need to be made, and the electromigrationphenomenon is avoided.

Owner:成都迈科科技有限公司

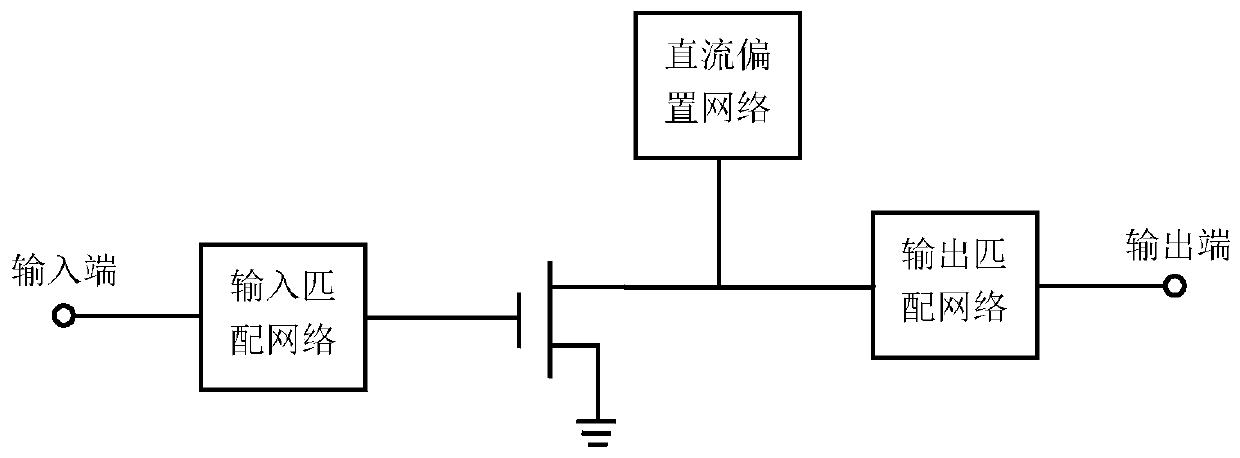

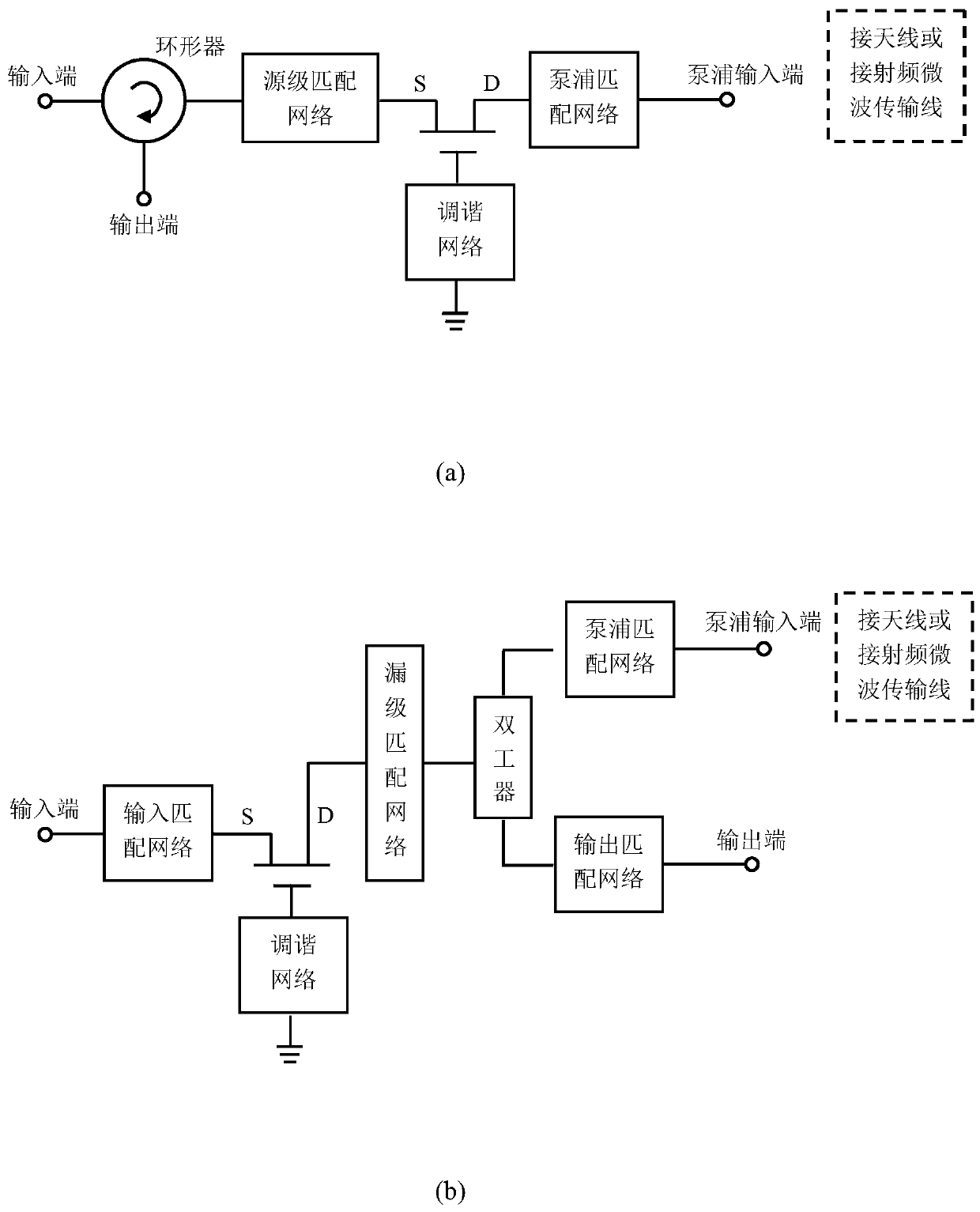

Microwave amplifier and implementation method thereof

ActiveCN110212872ASimple structureReduced operating temperature requirementsAmplifier modifications to reduce noise influenceAmplifier modifications to reduce temperature/voltage variationHeterojunctionHigh energy

The invention discloses a microwave amplifier and an implementation method thereof, and belongs to the technical field of quantum mechanics, semiconductor physics and electronics. Polarization exciters in a transistor containing a heterojunction are excited to a high-energy level through pumping microwaves, and the polarization exciters excited to the high-energy level are downwards transitioned to a specified energy level in an energy level region by utilizing a chain effect of an input signal in an energy level transition process, so that amplification of input signal power is realized. Theproblems of crosstalk of a bias circuit of the direct-current bias amplifier, high circuit wiring requirement, severe direct-current voltage ripple interference and pulse amplifier working environmentrequirement, large size, complex process, high cost and the like are effectively solved; the microwave amplifier is realized by adopting a transistor manufactured by adopting a general semiconductorprocess, the amplifier is simple in structure and low in working temperature requirement, the pumping power can be provided in a space radiation form, and the microwave amplifier has very good flexibility.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Steaming rack and steaming cabinet and oven having steaming rack

PendingCN108041997AReduce intensityAddress process complexityRoasters/grillsCooking insertsEngineeringProcessing cost

The invention relates to a steaming rack, a steaming cabinet having the steaming rack and an oven having the steaming rack. The steaming rack includes a frame, a cross beam, and a longitudinal beam; the frame is a rectangle formed through head-to-tail connection of metal pipes through welding; the cross beam is arranged between two opposite broad sides of the frame and fixed on the frame by usingthe metal pipes through welding, the frame and the cross beam form a base of the steaming rack, and the longitudinal beam is arranged between the two opposite long sides of the frame and fixed on thebase by using steel branches through welding. The frame and the cross beam of the steaming rack are made from the metal pipes and form the base together, the steel branches used for placing food are arranged on the base, and on one hand, the problem that the steaming rack made only from the steel branches is low in strength in the prior art is solved, on the other hand, the problem that in the prior art, the steaming rack made only from square pipes is complex in process and high in cost is solved. The steaming rack is high in strength and good in load-bearing ability, the processing technology is relatively simple, the processing cost is low, and the steaming rack is more suitable for large steaming cabinets and large ovens to use.

Owner:NANHAI BRANCH OF SHENZHEN GUOCHUANG MINGCHU COMML EQUIP MFG CO LTD

Polycarbonate styrene resin alloy and preparation method thereof

The invention relates to a polycarbonate styrene resin alloy and a preparation method thereof. The polycarbonate styrene resin alloy comprises the following raw material components in parts by weight:30-60 parts of polycarbonate resin, 25-60 parts of styrene resin, 5-30 parts of branched polycarbonate, 5-15 parts of assistant crosslinking resin and 0.5-1.0 part of a processing aid. The preparation method comprises the following steps: premixing the raw materials in a high-speed mixer for 3-10 min, and carrying out extrusion granulation on the premix through a double-screw extruder at the temperature of 230-280 DEG C to obtain the ultralow-gloss polycarbonate styrene resin alloy. Compared with the prior art, the polycarbonate styrene resin alloy with ultralow gloss is directly prepared bya one-step method without preparing low gloss master batch, the preparation method and the technological process are simple, the problems of insufficient gloss, uneven gloss distribution, deterioration of physical and mechanical properties, complex process, high cost and the like are solved, and the resin alloy is particularly suitable for the field of automotive interiors.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

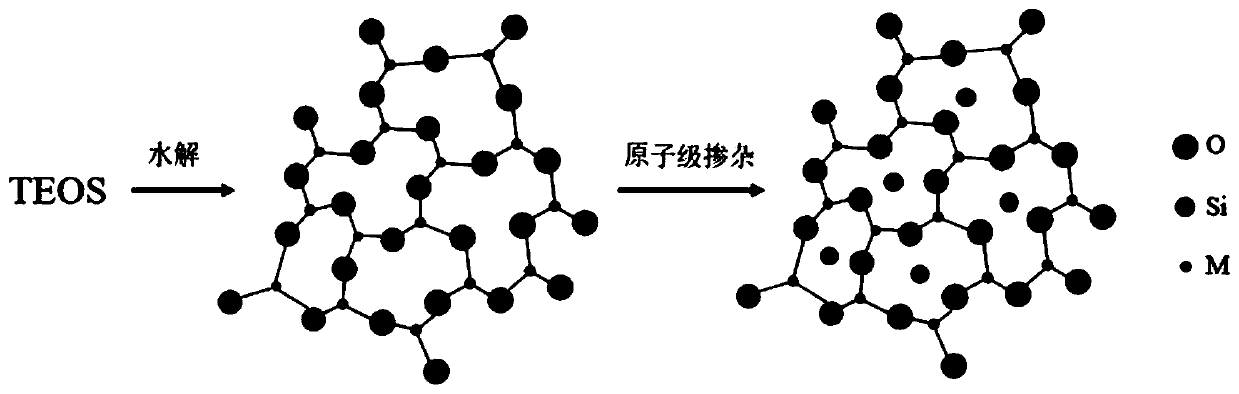

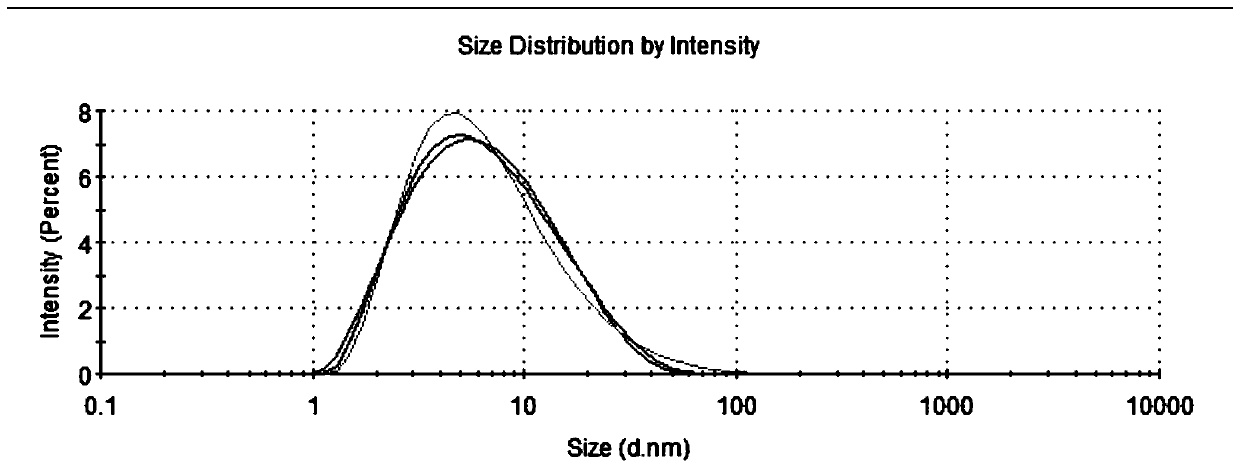

Method for preparing glass through 3D printing stereolithigraphy

PendingCN111018321AAddress process complexitySolve process costAdditive manufacturing apparatusGlass shaping apparatus3d printOrganic solvent

The invention discloses a method for preparing glass through 3D printing stereolithigraphy, belonging to the technical field of material manufacturing. The method comprises the following steps: mixingorganic molecules containing silicon elements, an organic solvent, deionized water and salt doped with metal ions for a reaction to obtain one or more metal ion-doped three-dimensional network framework solutions containing silicon-oxygen and the like; applying light or heat for further hydrolysis and condensation and carrying out aging to obtain a precursor of an inorganic component material for3D printing; then mixing the precursor with organic resin to prepare mixed slurry for 3D printing; carrying out printing, and then conducting drying and low-temperature degreasing treatment to removeorganic resin in a prefabricated glass body and to form a porous green glass body with nanopores; and carrying out sintering at high temperature to obtain a compact and transparent glass sample withuniform components. According to the invention, the uniformity of the glass sample reaches an atomic level, and the problem of non-uniform doping in the prior art is solved.

Owner:BEIJING UNIV OF TECH

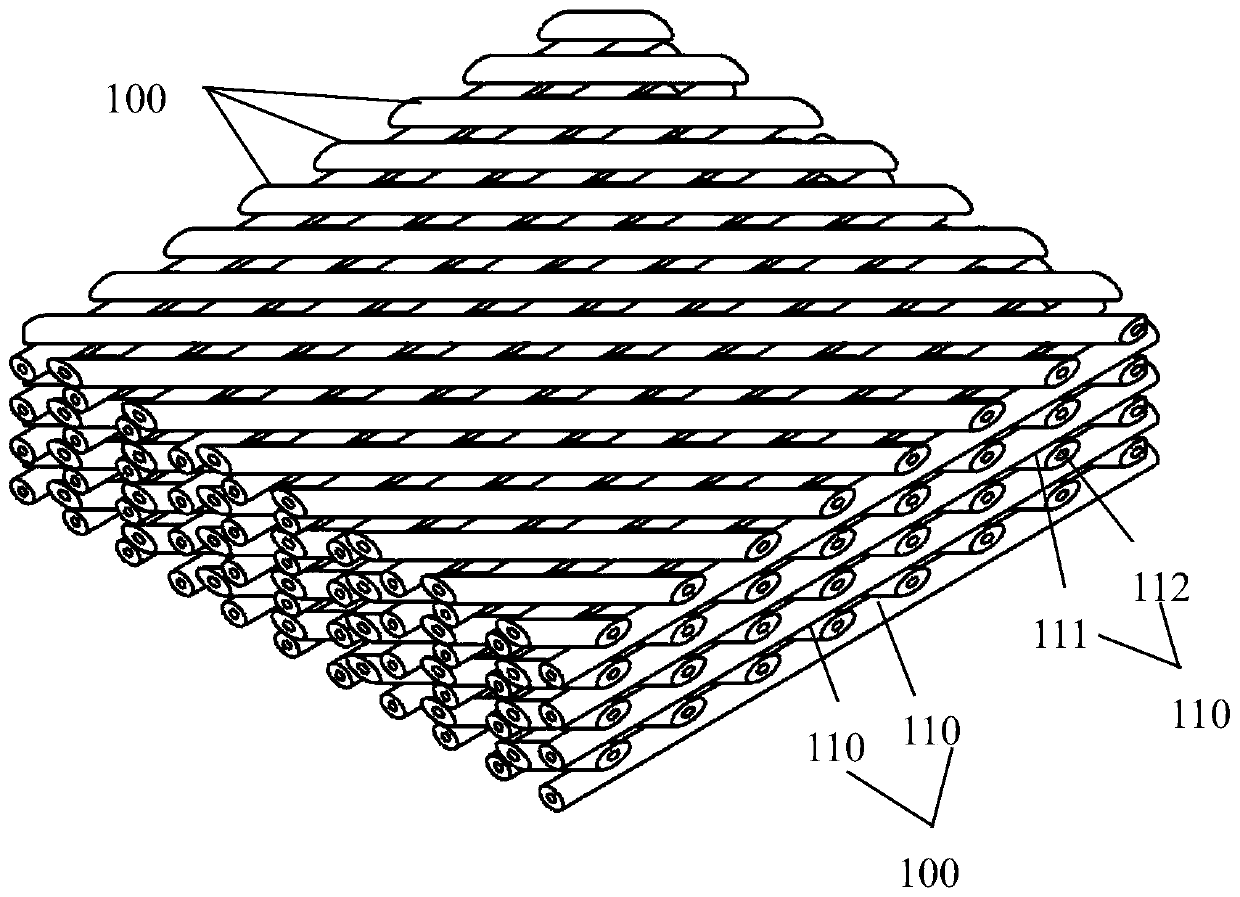

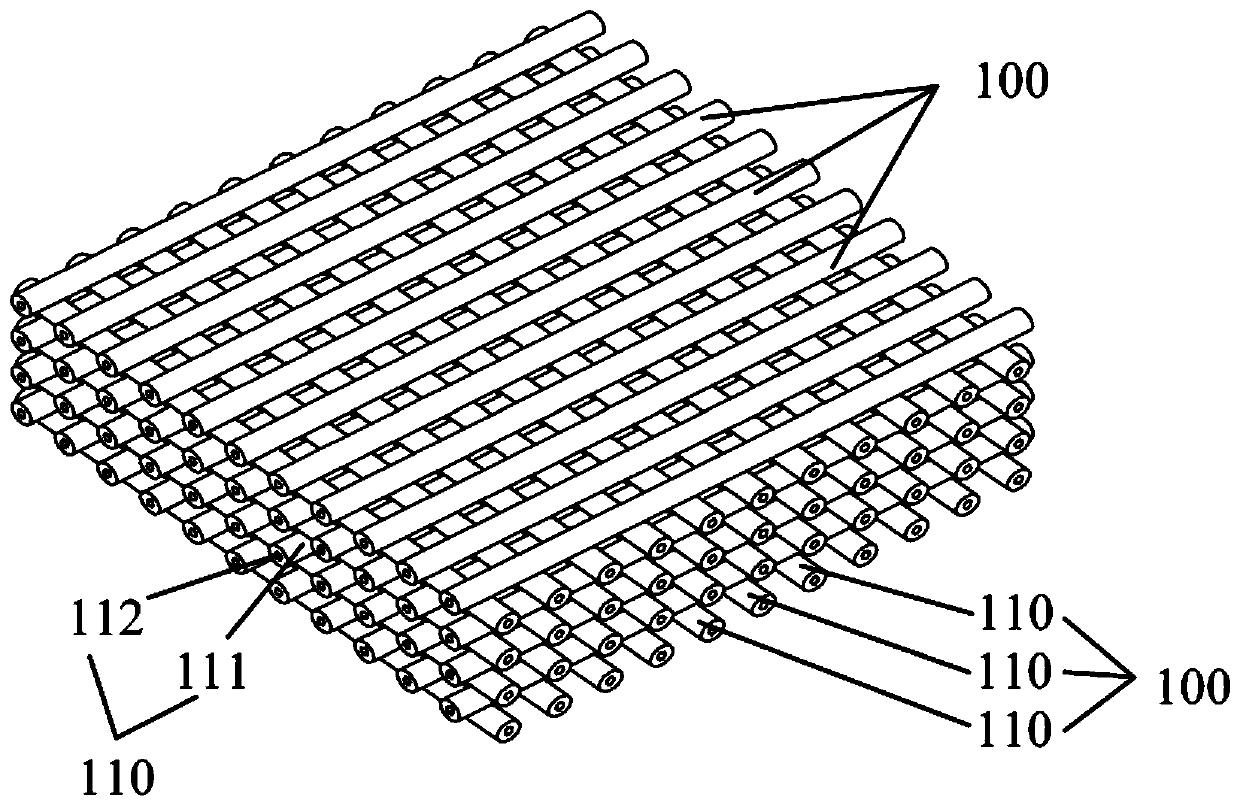

Silicone-rubber porous material array with elastic hollow fibers and preparing method thereof

ActiveCN109706625AEasy to compressImprove self-healing abilityAdditive manufacturing apparatusHollow filament manufactureFiberGraphics

The invention belongs to the technical field of porous-material additional materials, and particularly relates to a silicone-rubber porous material array with the elastic hollow fibers and a preparingmethod thereof. The porous material array comprises two layers or above of hollow fiber array structures, hollow fiber array structures of the layers adjacent up and down are intersected each other at a certain angle, and each layer of the hollow fiber array structure comprises multiple parallel elastic hollow fibers. The hollow fiber array structures obtained with the method serve as base materials, and formed buffering damping products or flexible electronic products have good compression and self-recovery capacity; different from an existing hollow silicone rubber manufacturing technology,the problems that in the prior art, the technology is complex, and the cost is high are solved, the silicone-rubber porous material array has the advantages of being simple in structure and capable of saving the labor cost, the time cost and the like, it is avoided that traditional hollow silicone rubber adopts a mold or a manual complex production technology, and different requirements of different users for 3D graphics, the geometric size and the like can be met.

Owner:JIANGNAN UNIV

Recovery device and recovery method for recovering selenium from copper anode slime

PendingCN113683061AAddress process complexitySolve process costEnergy inputElemental selenium/telluriumSulfur dioxideEnvironmental chemistry

The invention discloses a recovery device for recovering selenium from copper anode slime. The recovery device comprises a pretreatment system for crushing copper anode slime and uniformly mixing with sulfuric acid to obtain a pretreated material; a roasting-purifying system for roasting the pretreated material to generate flue gas containing selenium dioxide and sulfur dioxide and carrying out dust removal and purification on the flue gas; and an absorption and reduction system for absorbing the flue gas and synchronously reducing selenium dioxide to obtain crude selenium. The pretreatment system, the roasting-purifying system and the synchronous absorption and reduction system are connected in sequence. The invention also provides a recovery method for recovering selenium from copper anode slime by using the recovery device. The recovery device and the recovery method for recovering selenium from copper anode slime can effectively solve the problems of complex process, high cost, low selenium recovery rate, low crude selenium grade and the like in the process of recovering selenium from anode slime, the final overall recovery rate of selenium can reach 99% or above, and the crude selenium grade reaches 98% or above.

Owner:CENT SOUTH UNIV

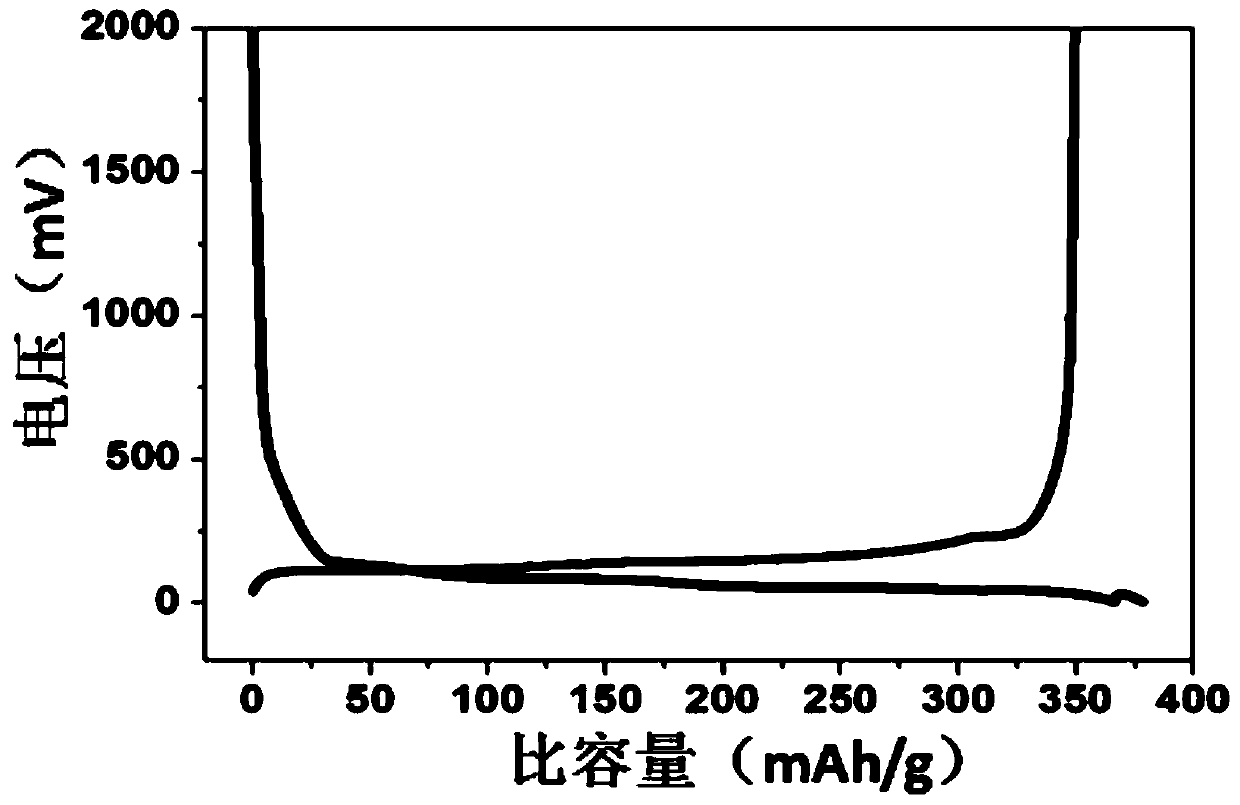

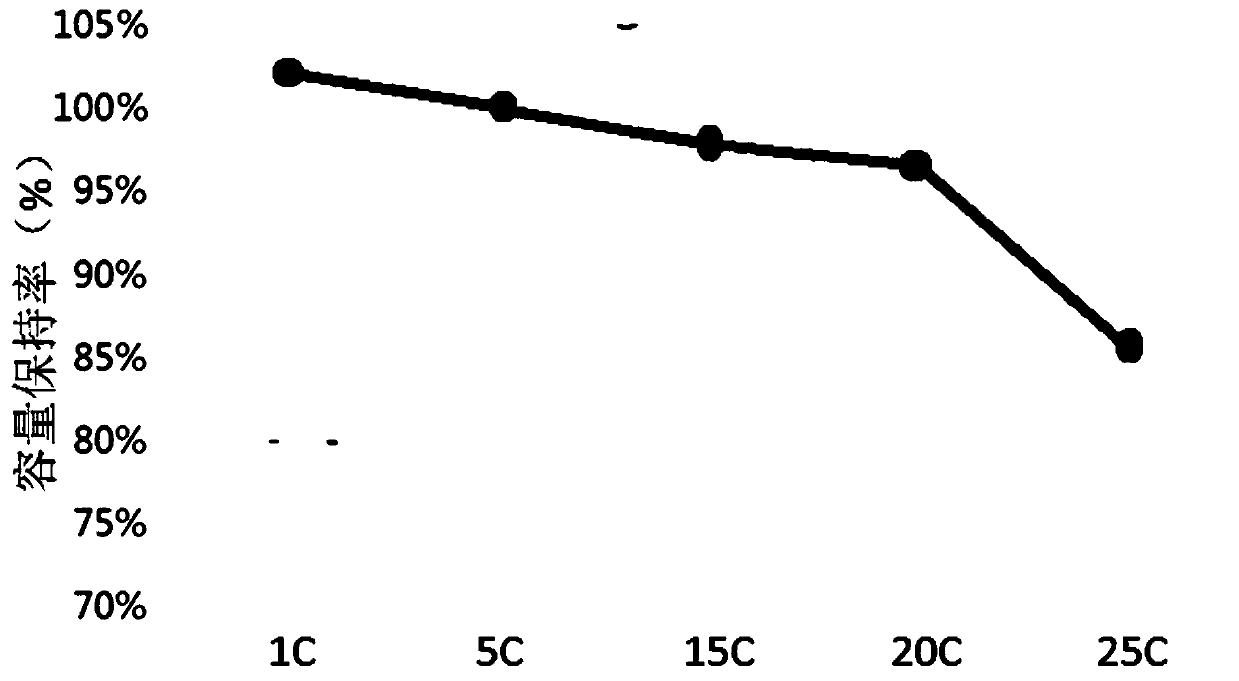

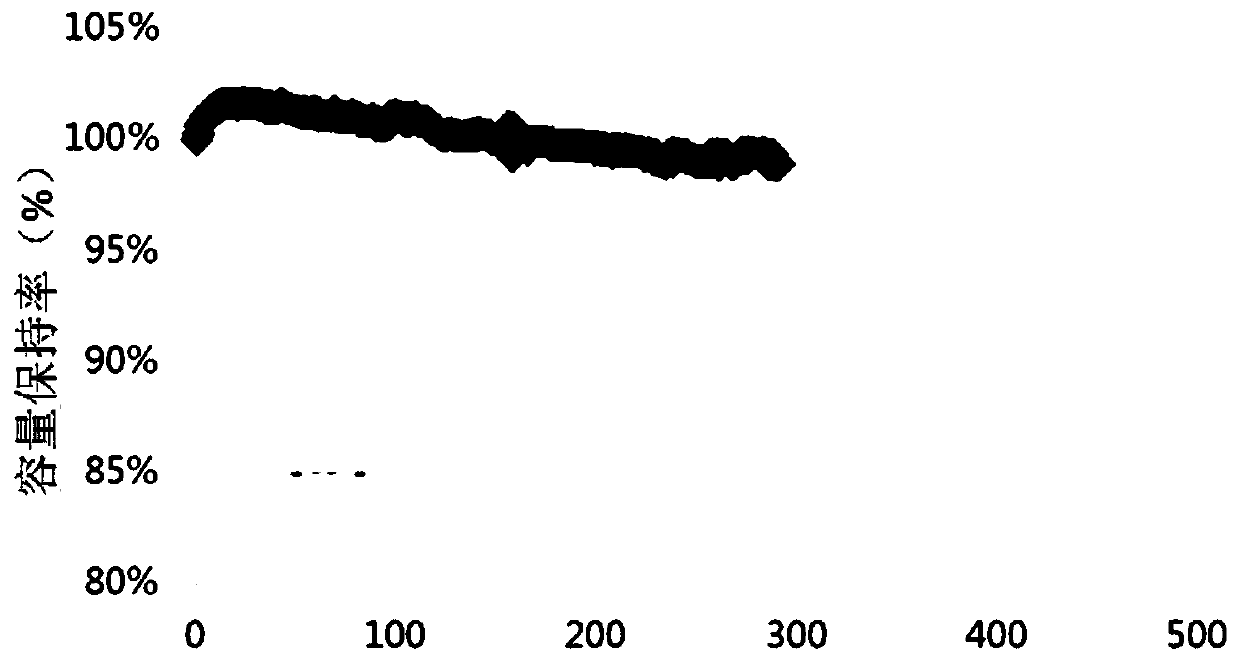

Preparation process of high-rate graphene composite material, negative electrode material and lithium battery

ActiveCN110600691AIncrease capacityIncrease compaction densityCell electrodesSecondary cellsHigh rateGraphene

The embodiment of the invention provides a preparation process of a high-rate graphene composite material, a negative electrode material and a lithium battery. The process comprises the steps of firstly crushing raw materials, then adding a coating agent and a binder for uniform mixing, carrying out stepped constant-temperature heat treatment to obtain a coarse material, and then after reshaping the coarse material, screening to obtain the high-rate graphene composite material. The material has the characteristics of high capacity and high compaction density, the preparation process is simple,the production cost is low, and the prepared product is stable in quality and is suitable for large-scale batch production. The embodiment of the invention also provides a negative electrode materialof the lithium ion battery and the lithium battery.

Owner:湖南海容新材料有限责任公司

Crystalline silicon solar cell manufacturing process

InactiveCN105514221AAddress process complexitySolve process costFinal product manufactureSemiconductor devicesCells panelEtching

The invention discloses a crystalline silicon solar cell manufacturing process. The process comprises the steps that step 1, a silicon wafer is cleaned, and then a flock surface is made; step 2, cleaning is performed before diffusion, and then phosphorus diffusion is performed; step 3, peripheral etching is performed, and then back junctions are removed; step 4, back electrode printing is performed, and then positive and negative electrode printing is performed; step 5, an antireflection film is prepared, then sintering is performed, and finally testing and grading are performed. The crystalline silicon solar cell manufacturing process has the advantages of being simple and lower in production cost and enabling the cell panel quality to be better.

Owner:CHENGDU ZHENZHONG ELECTRIC

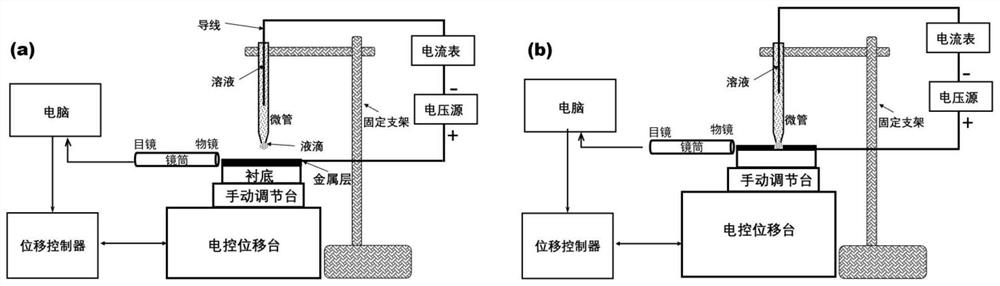

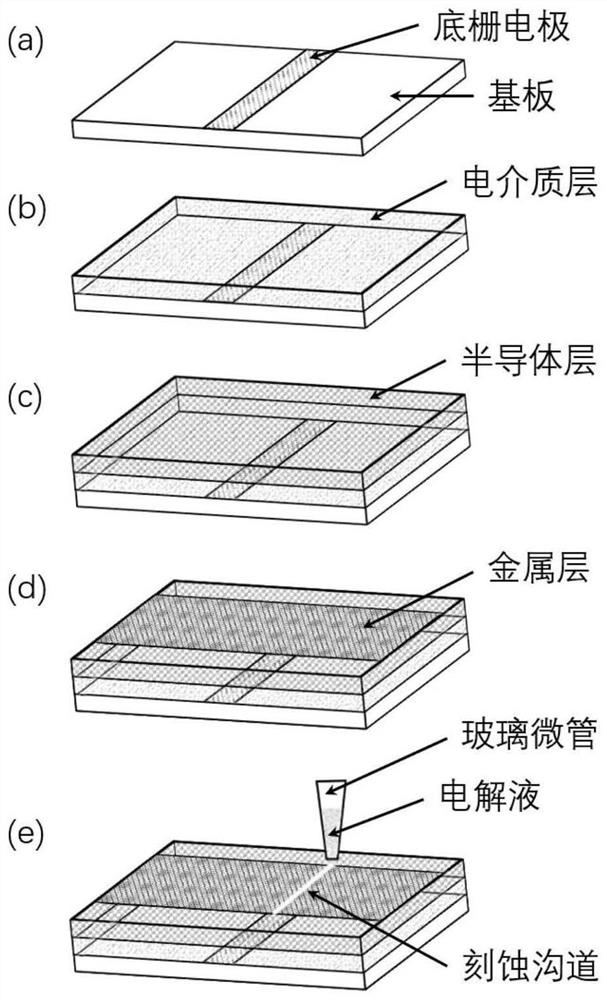

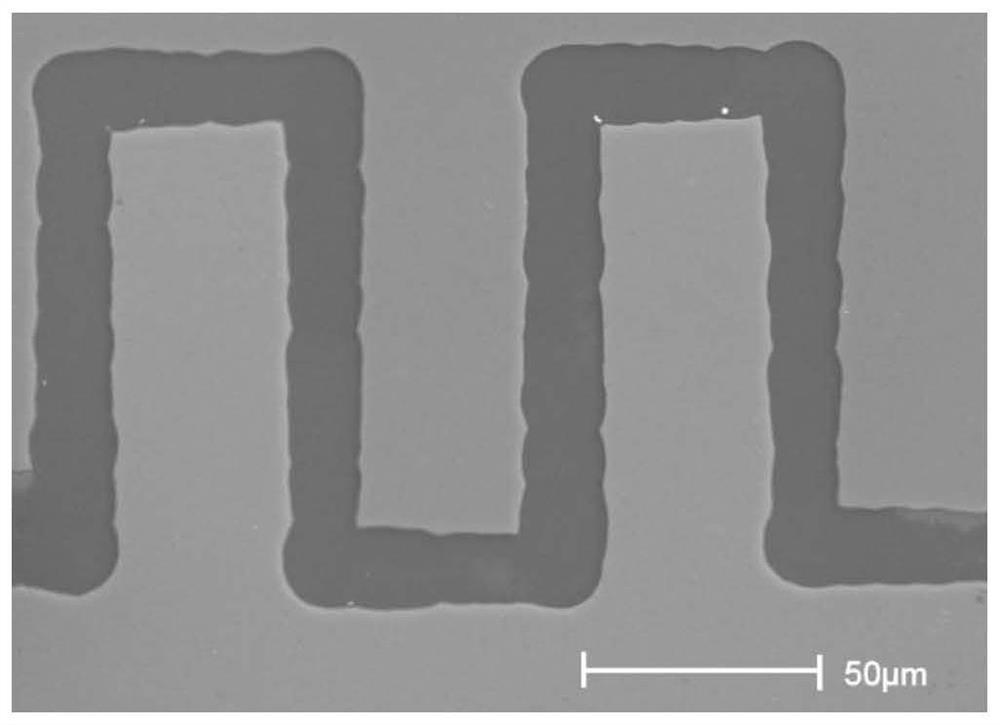

Preparation method of transistor channel, source electrode and drain electrode based on micro-region electrochemical etching

InactiveCN112885722AAddress process complexitySolve process costTransistorSemiconductor/solid-state device manufacturingElectrolytic agentMetallic materials

The invention belongs to the field of preparation of electronic devices, and particularly relates to a preparation method of a transistor channel, a source electrode and a drain electrode based on micro-region electrochemical etching. According to the method, an electrochemical principle and a micro-area self-confinement processing technology are combined, specifically, a meniscus is formed in a specific area of a substrate by using a microtube filled with electrolyte, and a patterned electrode is prepared by applying voltage between the electrolyte and a conductive metal layer of the substrate and enabling a needle tube to move relative to the substrate according to a planned path and speed. By efficiently and flexibly controlling the micro-region electrochemical etching of the metal material, the problems of complex process, high cost or low resolution in the existing mask electrode manufacturing process (such as photoetching and vacuum evaporation) are effectively solved. The method has important significance on laboratory research and industrial production.

Owner:FUDAN UNIV +1

Light environment-friendly aluminum alloy and preparation technology thereof

The invention discloses light environment-friendly aluminum alloy and a preparation technology thereof, and relates to the technical field of aluminum alloy casting. The light environment-friendly aluminum alloy comprises, by weight, 4.0%-6.0% of silicon, 0.2%-0.3% of ferrum, 2.5%-4.0% of copper, 0.2%-0.4% of manganese, 0.3%-0.5% of magnesium, 0.05%-1.0% of titanium, 0-0.5% of nickel, tin and lead, 0-0.2% of zinc, 0-0.05% of cadmium, mercury and chromium, the balance aluminum, 0-0.5% of other elements (the highest weight of each element accounts for 0.05%) and inevitable impurities. Accordingto the light environment-friendly aluminum alloy and the preparation technology thereof, the formula and the aluminum alloy preparation technology are reasonably designed, and the problems that an existing aluminum alloy production percent of pass is low, alloy product performance is poor, the technology is complex and manufacturing cost is high are solved.

Owner:铜陵市腾发铝制品加工有限责任公司

Dendrobium nobile pharmaceutical composition and application of dendrobium nobile pharmaceutical composition in toothpaste

PendingCN114432398ANo side effectsObvious anti-inflammatory and hemostatic effectOrganic active ingredientsCosmetic preparationsBleeding gumMouth care

The invention provides a dendrobium nobile pharmaceutical composition and application of the dendrobium nobile pharmaceutical composition in toothpaste. The pharmaceutical composition comprises the following components in parts by weight: 1-10 parts of dendrobium total alkaloids, 1-10 parts of dendrobium total polysaccharides and 1-10 parts of dendrobium total bibenzyl. The pharmaceutical composition is safe and reliable to human bodies, has no toxic or side effect, has no irritation to mucous membranes, has obvious anti-inflammatory and hemostatic effects, can be used in oral care compositions such as toothpaste, and is used for preventing and treating gingival bleeding and the like.

Owner:ZUNYI MEDICAL UNIVERSITY

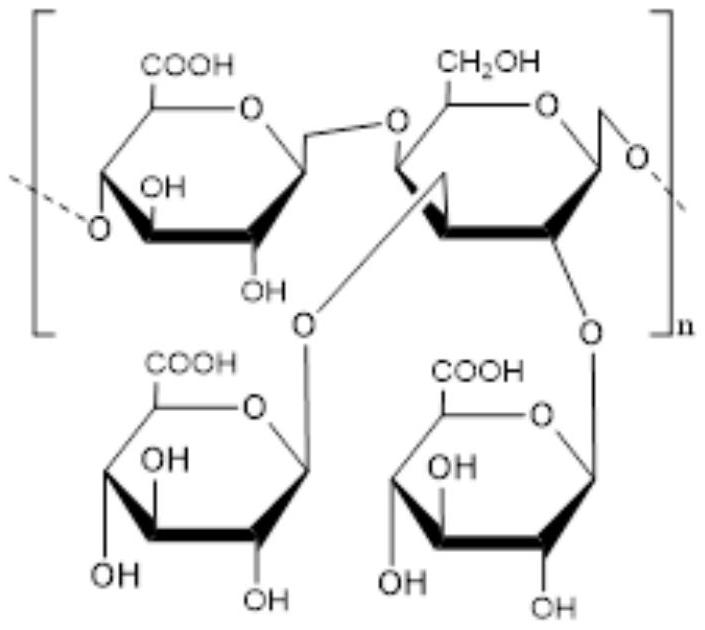

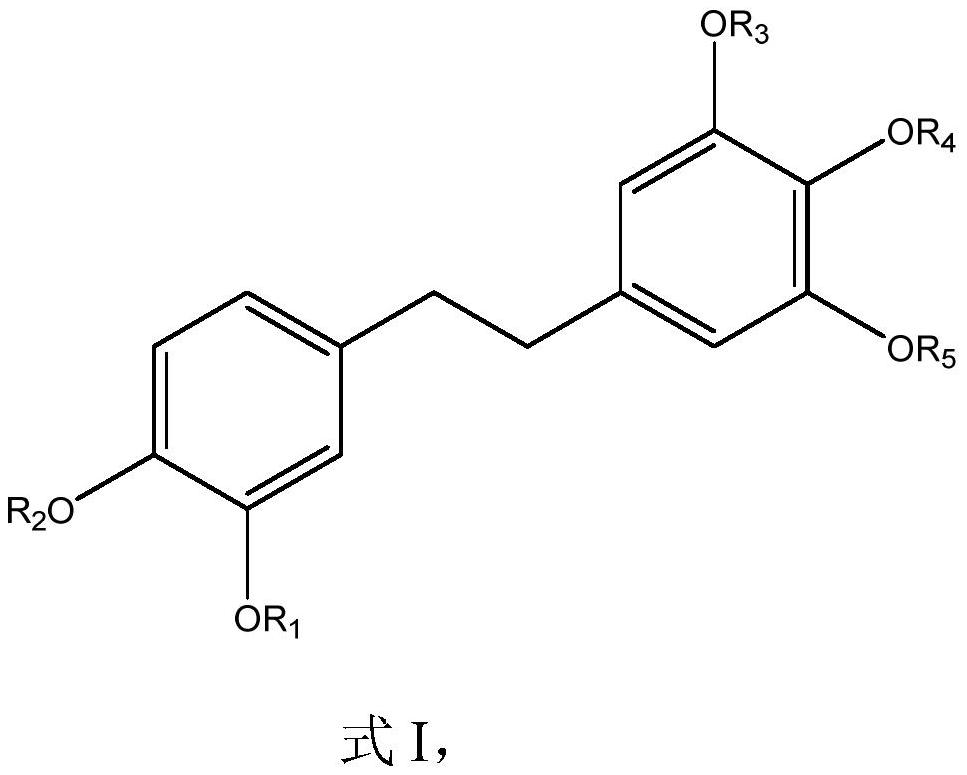

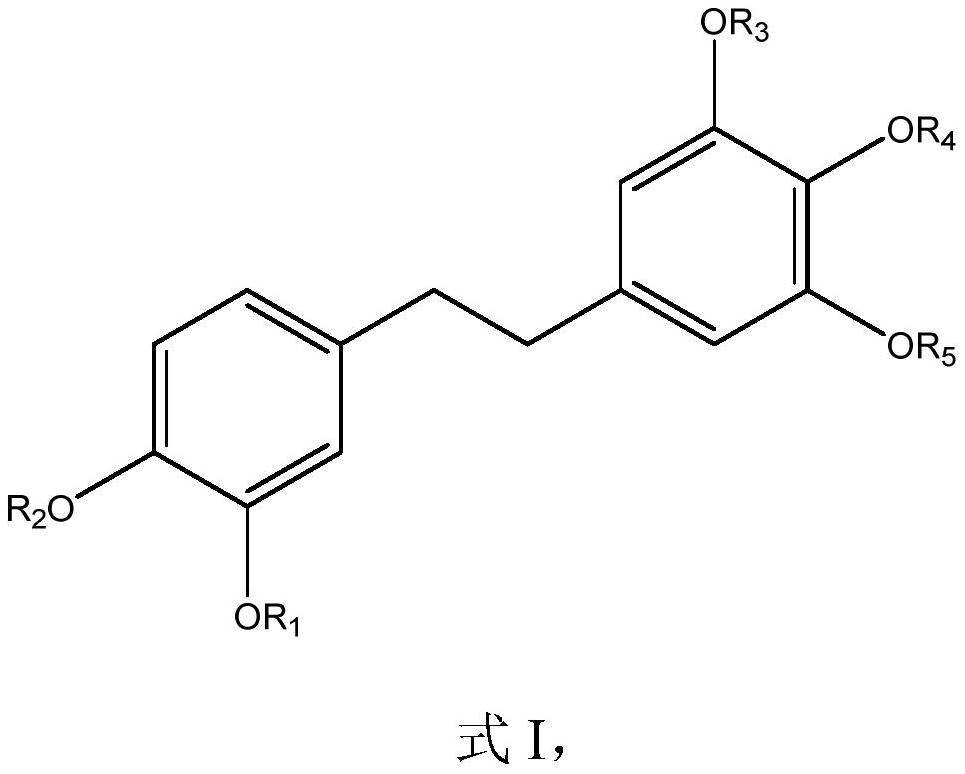

Active ingredient composition derived from dendrobium officinale and gynostemma pentaphylla and application of active ingredient composition

PendingCN114712369ANo side effectsNon-irritatingCosmetic preparationsAntipyreticBULK ACTIVE INGREDIENTFacial cream

The invention provides an active ingredient composition derived from dendrobium officinale and gynostemma pentaphylla and application of the active ingredient composition. The composition comprises a compound as shown in a formula I or a pharmaceutically acceptable solvate thereof and gynostemma pentaphyllum secondary saponin, wherein the weight ratio of the compound as shown in the formula I to the gynostemma pentaphyllum secondary saponin is (1-10): (1-10). The two components in the composition have synergistic whitening activity, and the composition is safe and reliable to human bodies, free of toxic and side effects and free of irritation to mucous membranes, and can be used for preparing whitening cosmetics or skin care products, such as face cream, facial masks, hand cream or facial cleanser.

Owner:ZUNYI MEDICAL UNIVERSITY

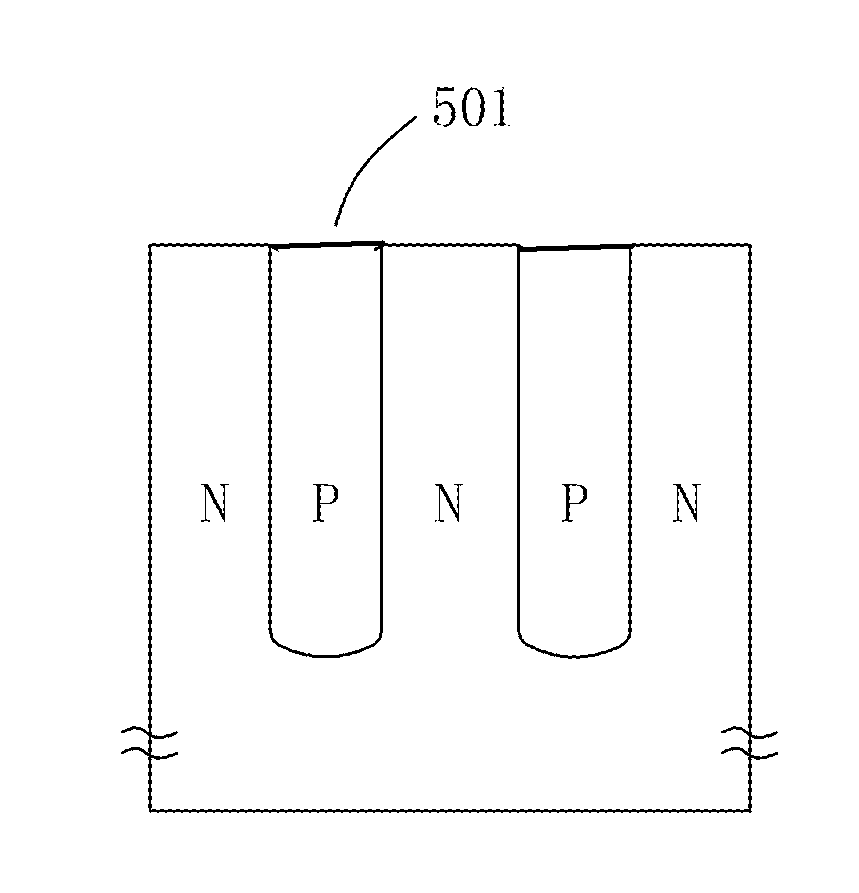

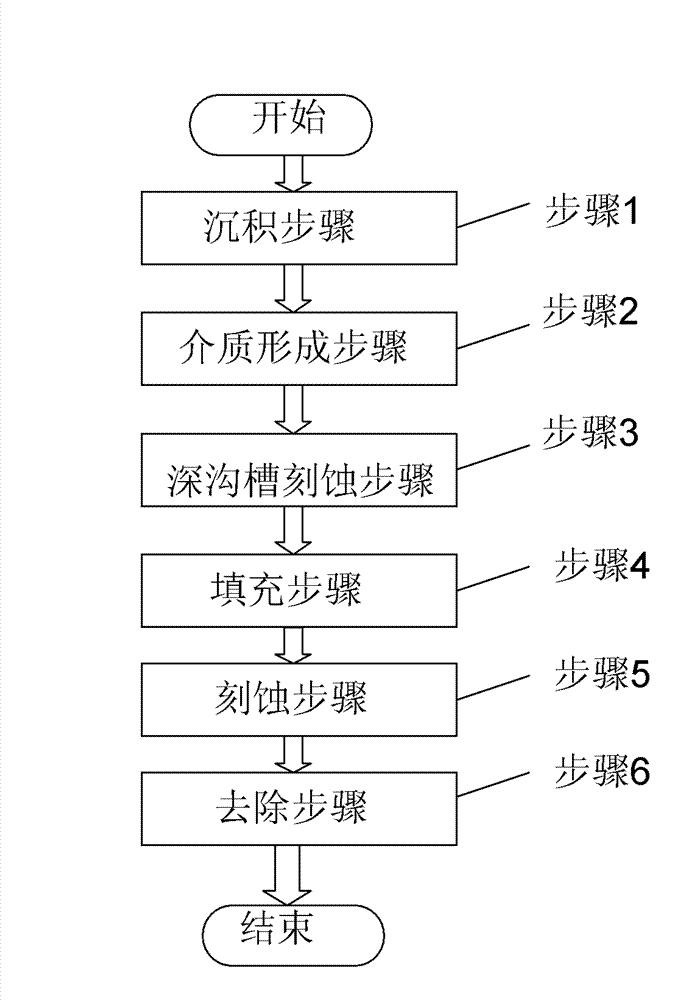

Formation method of deep groove super positive-negative (PN) junction

ActiveCN102820212AAddress process complexitySolve process costSemiconductor/solid-state device manufacturingSemiconductor devicesEpitaxial materialOptoelectronics

The invention relates to a formation method of a deep groove super PN junction. The method comprises the steps of depositing an epitaxial layer on a substrate; forming a first dielectric layer and a second dielectric layer on the epitaxial layer sequentially; forming a deep groove on the epitaxial layer; filling the deep groove with epitaxial materials till the specified height of the second dielectric layer is exceeded; etching epitaxial materials, the first dielectric layer and the second dielectric layer till the interface positions of the first dielectric layer and epitaxial materials with etching gases; and removing the first dielectric layer and the second dielectric layer to achieve planarization of epitaxial materials. By the aid of the formation method, planarization of silicon can be achieved by using the method which is compatible with existing processes, the formation method has the advantages of being simple in process, high in efficiency and low in process cost, and the problem that parameters of silicon (Si) devices are not stable due to chemical-mechanical polishing (CMP) can be effectively solved.

Owner:CSMC TECH FAB2 CO LTD

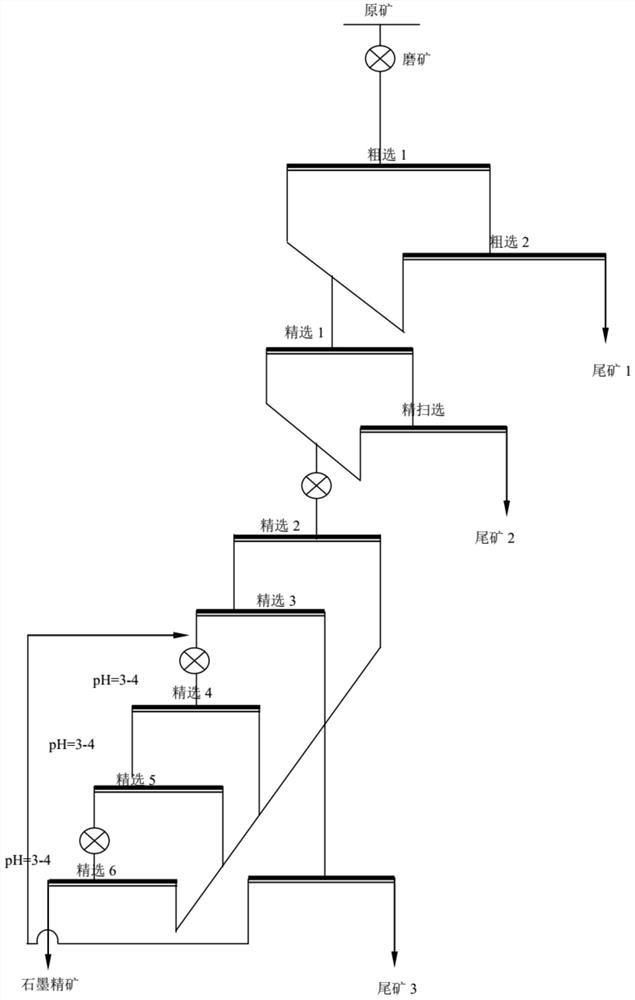

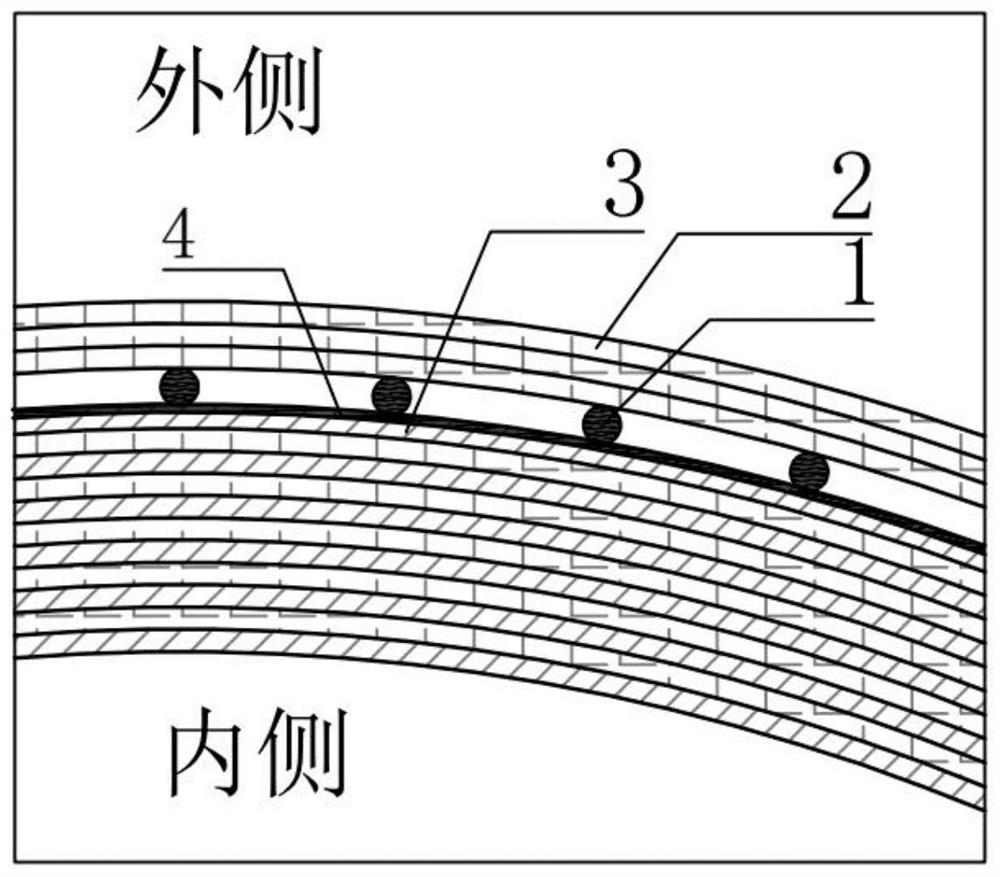

A kind of beneficiation and purification method of low-grade microcrystalline graphite

ActiveCN109607527BShort processHigh enrichment ratioCarbon compoundsFlotationFoaming agentProcess engineering

The invention relates to a method for beneficiation and purification of low-grade microcrystalline graphite. Firstly, the ore of microcrystalline graphite is sequentially crushed and ground, and a collector and a foaming agent are added to the ground pulp, stirred, and graphite flotation is carried out. Obtain graphite coarse concentrate and tailings 1; conduct a selection and a sweep of graphite coarse concentrate to obtain concentrated concentrate and tailings 2; conduct regrinding and selection on the selected concentrate to obtain a re-grinding Grinding concentrated concentrate and regrinding concentrated tailings; regrinding 1-2 times of regrinding concentrated ore, and then performing 2-4 times of beneficiation under acidic conditions to obtain high-grade graphite concentrate and regrinding Mill tailings. The mineral processing and purification method of the present invention has a short process flow and a high enrichment ratio, and solves the problems of low-grade aphanitic graphite mineral processing technical indicators, low graphite concentrate grade, low recovery rate, complicated process, and high cost, and makes low-grade microcrystalline Graphite ore is efficiently, economically and rationally utilized.

Owner:HUNAN RES INST FOR NONFERROUS METALS

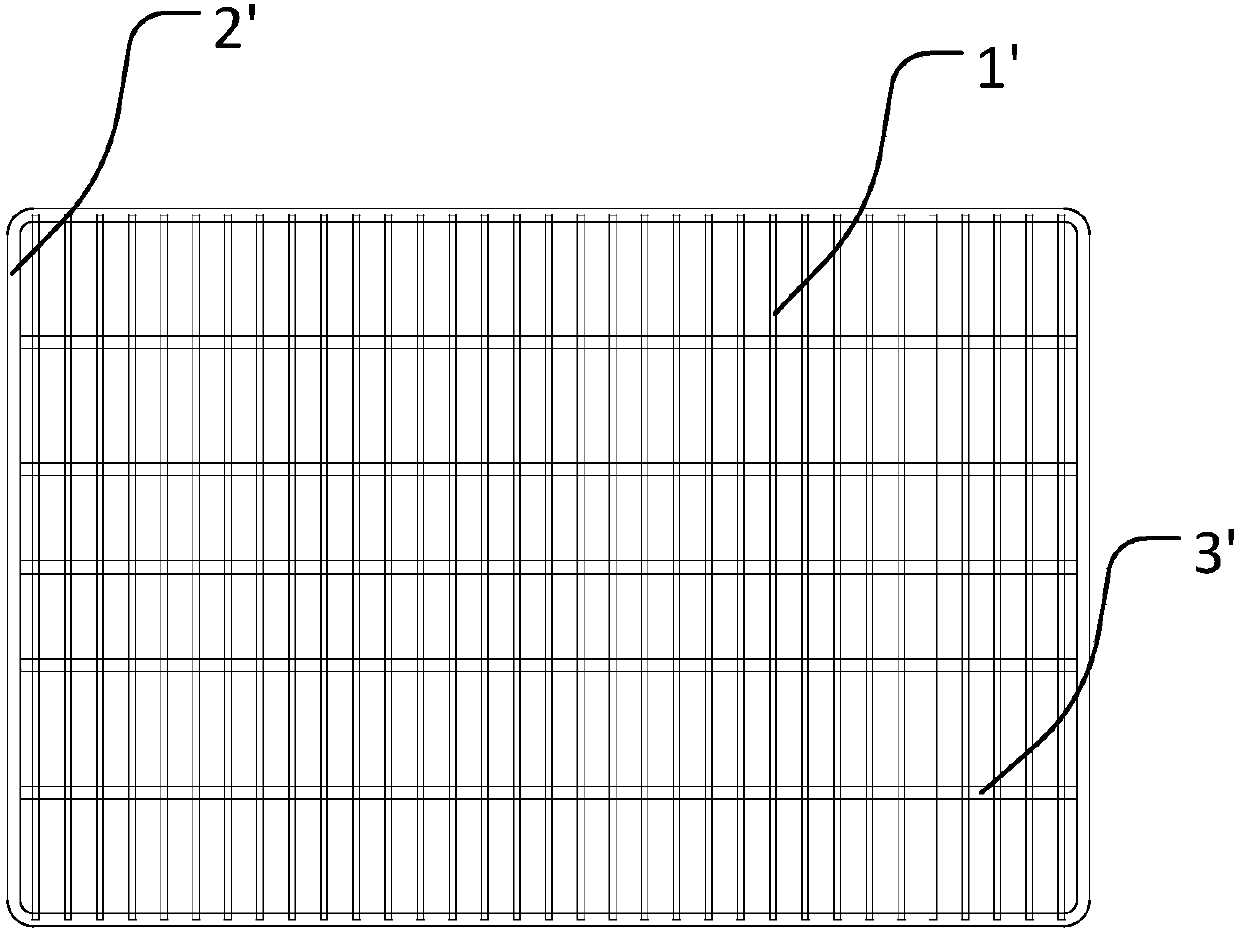

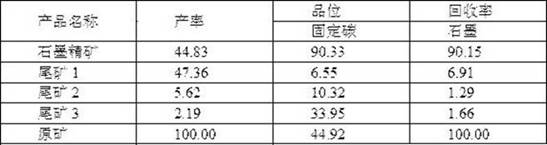

Millimeter wave antenna housing with electromagnetic shielding function and manufacturing method of antenna housing

PendingCN113782963AImprove normativeImprove reliabilityRadiating element housingsAntenna couplingsEngineeringElectromagnetic shielding

The embodiment of the invention provides a millimeter wave antenna housing with an electromagnetic shielding function and a manufacturing method of the antenna housing, relates to the technical field of antenna housings and manufacturing methods thereof, and aims to improve the stealth and wave-transparent performance of the antenna housing. The antenna housing sequentially comprises an inner composite material layer, a shielding metal grid, a double-sided conductive copper foil and an outer composite material layer from inside to outside. The inner composite material layer and the outer composite material layer are formed by alternately laying cut composite materials; the metal shielding grid is formed by metal wires; a circle of double-sided conductive copper foil is laid on the inner side composite material layer, soldering tin points are hung on the double-sided conductive copper foil, and the shielding metal grid is laid on the double-sided conductive copper foil.

Owner:湖北宽谱航空科技有限公司

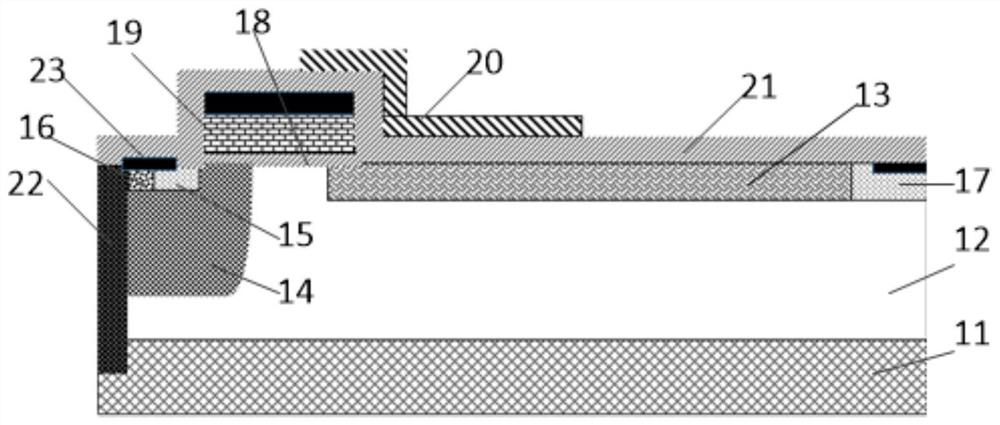

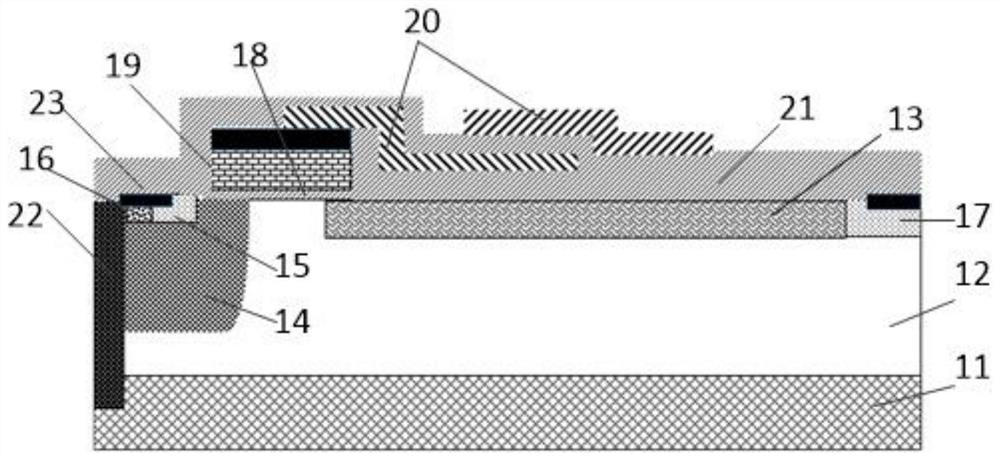

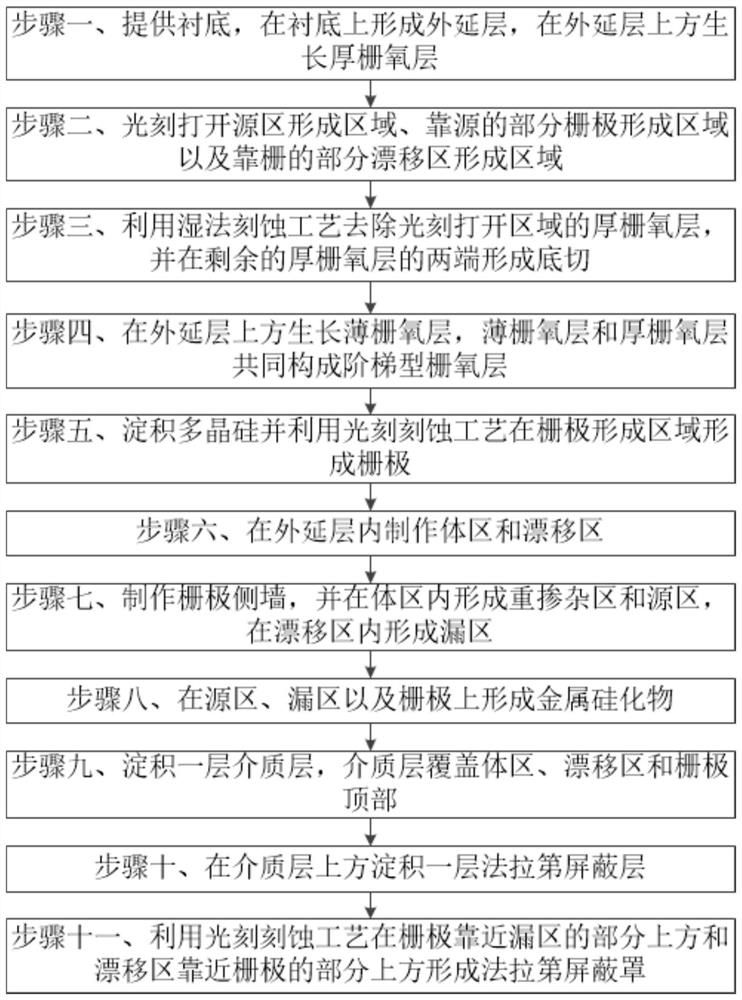

RFLDMOS device and manufacturing method thereof

PendingCN114429908AAddress process complexitySolve process costSemiconductor/solid-state device detailsSolid-state devicesLDMOSElectrical resistance and conductance

The invention provides a radio frequency (RF) laterally diffused metal oxide semiconductor (LDMOS) device and a manufacturing method thereof, which are characterized in that a substrate is provided, an epitaxial layer is formed on the substrate, a thick gate oxide layer is grown above the epitaxial layer, a source region forming region, a partial gate forming region close to a source and a partial drift region forming region close to a gate are opened by photoetching, and the thick gate oxide layer in the photoetching opening region is removed by utilizing a wet etching process. And forming undercuts at the two ends of the remaining thick gate oxide layer, growing a thin gate oxide layer above the epitaxial layer, forming a stepped gate oxide layer by the thin gate oxide layer and the thick gate oxide layer, and performing a subsequent process to form the stepped Faraday shielding case. According to the stepped Faraday shielding case, the breakdown voltage is considered, meanwhile, the hot carrier performance is improved, the resistance to ground of the Faraday shielding case is reduced, the reliability and the frequency characteristic of a device are effectively improved, and the single-layer Faraday shielding case can achieve the effect of a traditional Faraday shielding case with two layers or even three layers; the photoetching level of the Faraday shielding case is reduced, the process is simplified, and the cost is saved.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com