Formation method of deep groove super positive-negative (PN) junction

A technology of deep trenches and PN junctions, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as high cost and difficult process control, achieve low cost, avoid Si device parameter instability, and improve efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Presented below are some of the many possible embodiments of the invention, intended to provide a basic understanding of the invention. It is not intended to identify key or critical elements of the invention or to delineate the scope of protection.

[0033] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

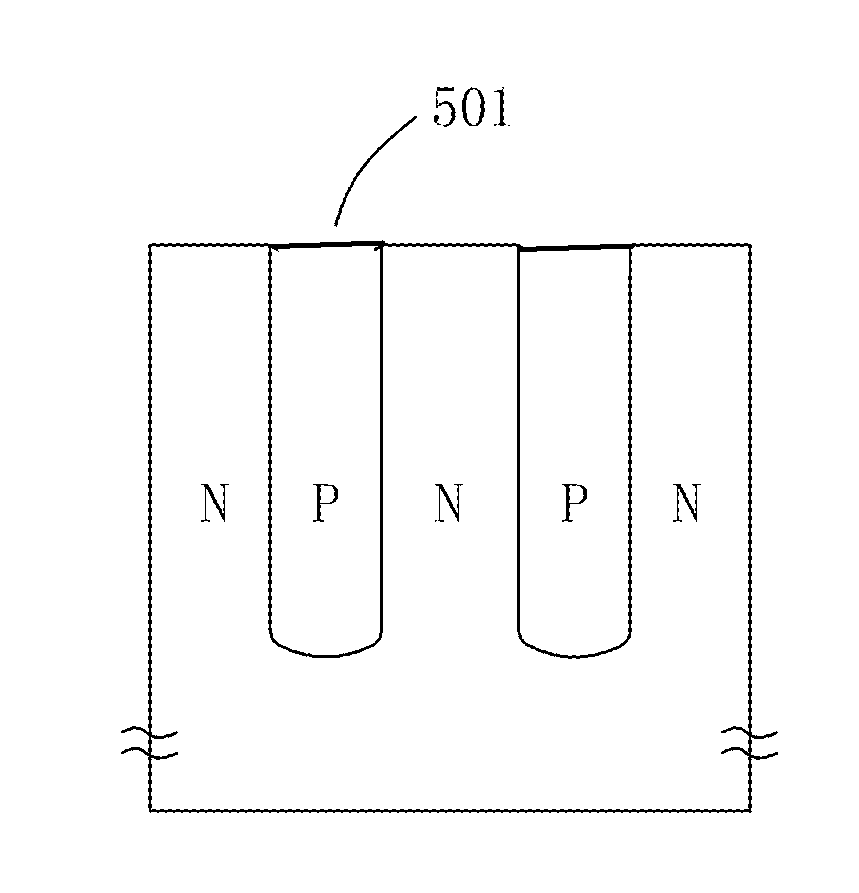

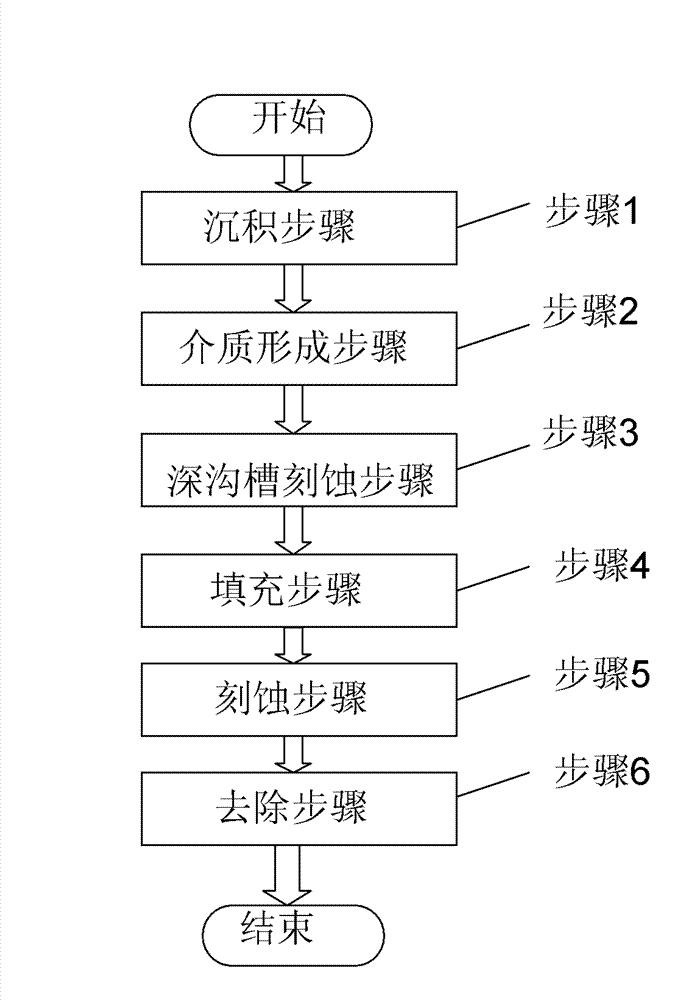

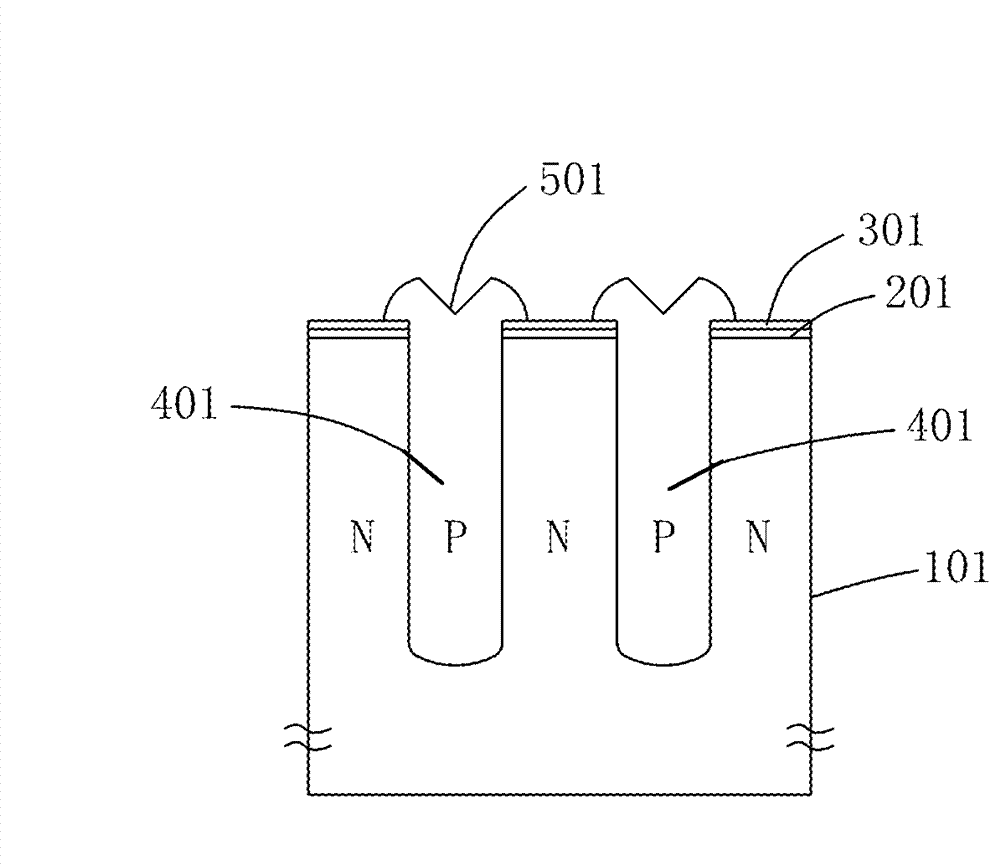

[0034] Below, refer to Figure 1 ~ Figure 4 , a method for forming a deep trench super PN junction according to an embodiment of the present invention will be described.

[0035] figure 1 It is an overall flowchart showing the process of forming a super PN junction according to an embodiment of the present invention.

[0036] First, if figure 1 Shown, super PN junction forming method of the present invention mainly comprises:

[0037] Step 1: A deposition step of depositing an epitaxial layer on a substra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com