Recovery device and recovery method for recovering selenium from copper anode slime

A recovery device and copper anode slime technology, applied in the field of metallurgy, can solve the problems of high cost, complex process, large amount of waste water and waste residue, etc., and achieve the effect of reducing process cost and simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

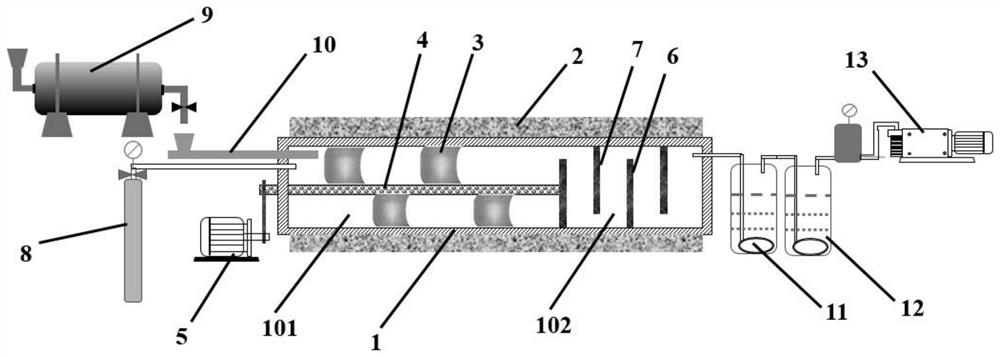

[0059] Such as figure 1 As shown, the recovery device for reclaiming selenium from copper anode slime of the present embodiment includes:

[0060]Pretreatment system, used for crushing copper anode slime and uniformly mixing with sulfuric acid to obtain pretreated materials;

[0061] Roasting-purification system, used for roasting pretreated materials to generate flue gas containing selenium dioxide and sulfur dioxide, and dedusting and purifying the flue gas;

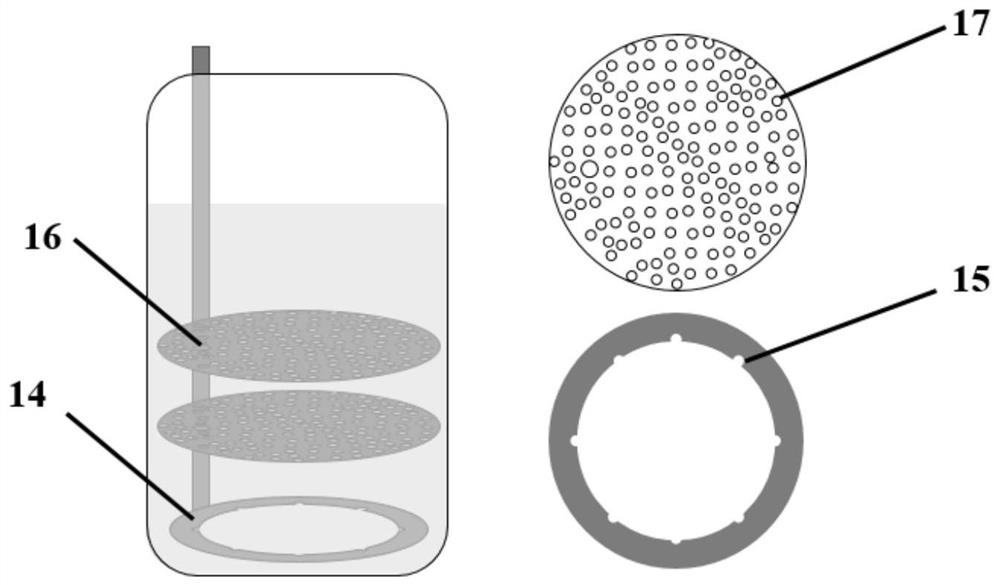

[0062] The absorption reduction system is used to absorb flue gas and simultaneously reduce selenium dioxide to obtain crude selenium;

[0063] The pretreatment system, roasting-purification system and synchronous absorption reduction system are connected in sequence.

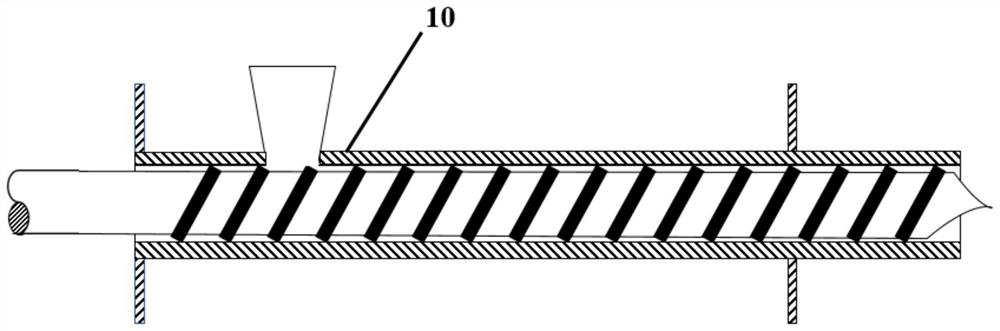

[0064] In this embodiment, the roasting-purification system includes a roasting furnace 1 arranged horizontally. The roasting furnace 1 is provided with a feed port and a gas outlet. The side of the roasting furnace 1 near the feed port is provided wi...

Embodiment 2

[0079] The recovery device of this embodiment is the same as that of Embodiment 1.

[0080] The method for recovering selenium from copper anode slime utilizing the above-mentioned recovery device of the present embodiment comprises the following steps:

[0081] Add copper anode slime and sulfuric acid to the wet grinding device 9 at a volume-to-mass ratio of 0.7:1, open the valve at the discharge port after grinding for 4 hours, and add the mixture to the screw extrusion feeding device 10, and the screw extrusion feeding device 10 After being extruded and conveyed, the uniformly mixed slurry is transported to the roasting area 101, and the heating furnace jacket 2 is turned on to control the temperature in the furnace, and the temperature is controlled at 5 stages to stabilize at about 300°C, 390°C, 450°C, 570°C, and 650°C At the same time, open the terminal vacuum pump assembly 13, observe that the pressure in the negative pressure buffer tank is about -8000Pa, and control t...

Embodiment 3

[0083] The recovery device of this embodiment is the same as that of Embodiment 1.

[0084] The method for recovering selenium from copper anode slime utilizing the above-mentioned recovery device of the present embodiment comprises the following steps:

[0085] Add copper anode slime and sulfuric acid to the wet grinding device 9 at a volume-to-mass ratio of 2:1, open the outlet valve after grinding for 3 hours, and add the mixture to the screw extrusion conveying device 10, and the screw extruding conveying device 10 After being extruded and conveyed, the uniformly mixed slurry is transported to the roasting area 101, and the heating furnace jacket 2 is turned on to control the temperature in the furnace, and the 5-stage control temperature is stable at about 250°C, 350°C, 450°C, 585°C, and 620°C , and open the terminal vacuum pump assembly 13 at the same time, observe that the pressure in the negative pressure buffer tank is about -14000Pa, and control the ventilation rate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com