Method for preparing glass through 3D printing stereolithigraphy

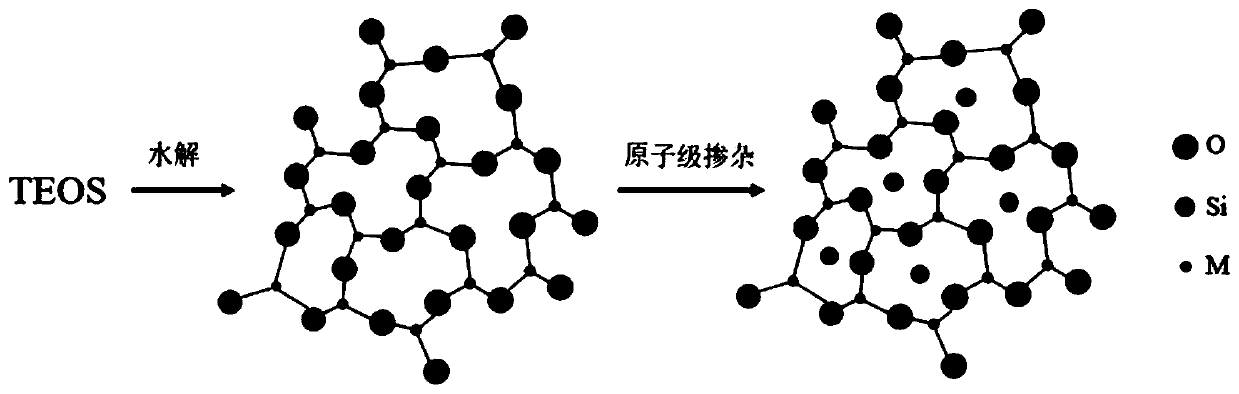

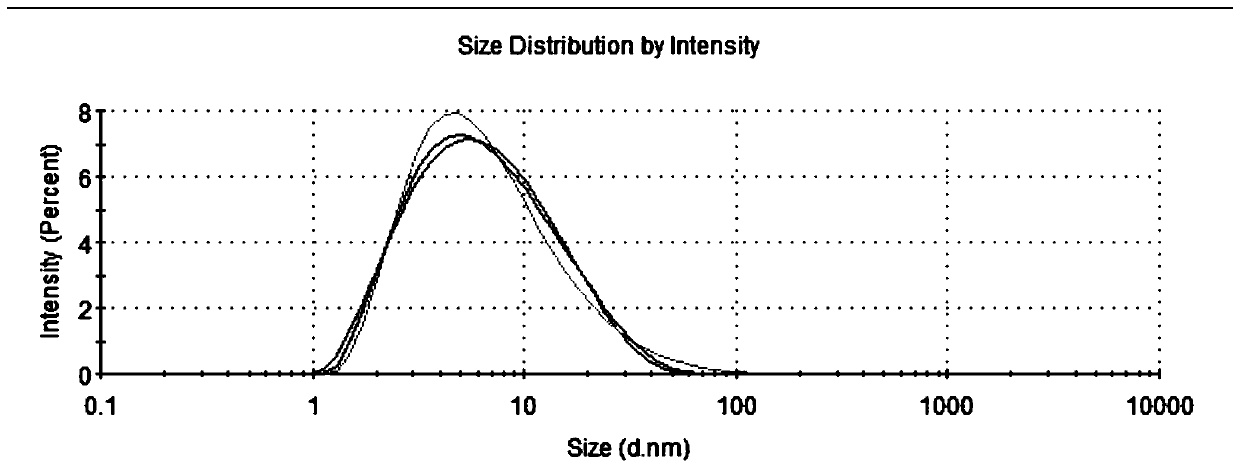

A photocuring molding and 3D printing technology, applied in the field of material manufacturing, can solve the problems of unguaranteed mixing uniformity and difficulty in obtaining glass with uniform composition, achieve uniform size distribution, and solve the effect of uneven doping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A kind of preparation of laser gain glass, concrete method and steps are as follows:

[0035] With 34.3 g of absolute ethanol as a solvent, 35.9 g of tetraethyl orthosilicate and 19.6 g of deionized water were added and mixed uniformly, and the pH value of the solution was adjusted with nitric acid. Weigh 0.293g of erbium nitrate pentahydrate and add it, and stir evenly at 30°C to 80°C to obtain a clear solution;

[0036] Heat the solution at 60°C to 150°C, remove part of the inorganic solvent and organic solvent ethanol, and obtain a sol with a viscosity greater than 50cp, which is used as a 3D printing precursor;

[0037] Mix the sol with the organic resin (50wt%: 50wt%) and stir evenly. The organic resin is in the form of adding raw materials, which is initiated by 53.3wt% propylene glycol acrylate, 44.7wt% hydroxyethyl methacrylate and 2wt% photoinitiated Agent azodiisopropyl imidazoline (referred to as AIP, VA-061 initiator). Ultrasonic stirring is uniform, and a...

Embodiment 2

[0042] A preparation of aluminosilicate multi-component glass, the preparation method and steps are as follows:

[0043] First prepare the glass 3D printing precursor. Take 34.3g of absolute ethanol as a solvent, mix 35.9g of tetraethyl orthosilicate and 19.8g of deionized water evenly, weigh 3.325g of AlCl 3 Add it into the solution, add dropwise ethylenediamine to adjust the pH value of the solution to be alkaline, and prepare a clear solution;

[0044]Heat the solution at 30°C to 120°C to remove most of the solvent to obtain a sol with a viscosity greater than 50cp;

[0045] The sol is mixed with resin (45wt%: 55wt%), and the resin is added in the form of raw materials, consisting of 50wt% 1,6 ethylene glycol diacrylate, 47wt% bisphenol A epoxy acrylate polyester acrylate and 3wt% % of azobisisobutyronitrile (AIBN) composition. Vibrate and stir to obtain a multi-component glass 3D printing paste with a viscosity of 30cp-100cp;

[0046] Pour the glass 3D printing slurry ...

Embodiment 3

[0050] A preparation of fluorescent borosilicate glass, the preparation method and steps are as follows:

[0051] Take 31.7g of absolute ethanol as a solvent, take 26.1g of ethyl orthosilicate, 11.3g of tributyl borate and 18.8g of deionized water and mix evenly, weigh 0.759g of cerium trichloride heptahydrate and add it to the solution, add ethyl orthosilicate dropwise Diamine adjusts the pH value of the solution to be alkaline, and prepares a clear solution;

[0052] Heat the solution at 30° C. to 120° C. to remove part of the solvent to obtain a sol with a viscosity greater than 50 cp.

[0053] The sol and resin are evenly mixed, and the glass preform is obtained by 3D printing according to the set three-dimensional graphics; the porous glass green embryo is obtained after degreasing and removing the organic resin at a low temperature of 100 ° C to 500 ° C; the transparent and dense luminous glass is obtained by sintering at a high temperature of 1175 ° C. Other concrete p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com