Steaming rack and steaming cabinet and oven having steaming rack

A technology for steaming racks and ovens, which is applied in the field of steaming racks and steaming cabinets and ovens with the steaming racks, which can solve the problems of complex processing technology, high production cost, and low strength, and achieve simple processing technology, low production cost, and load-bearing The effect of good ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

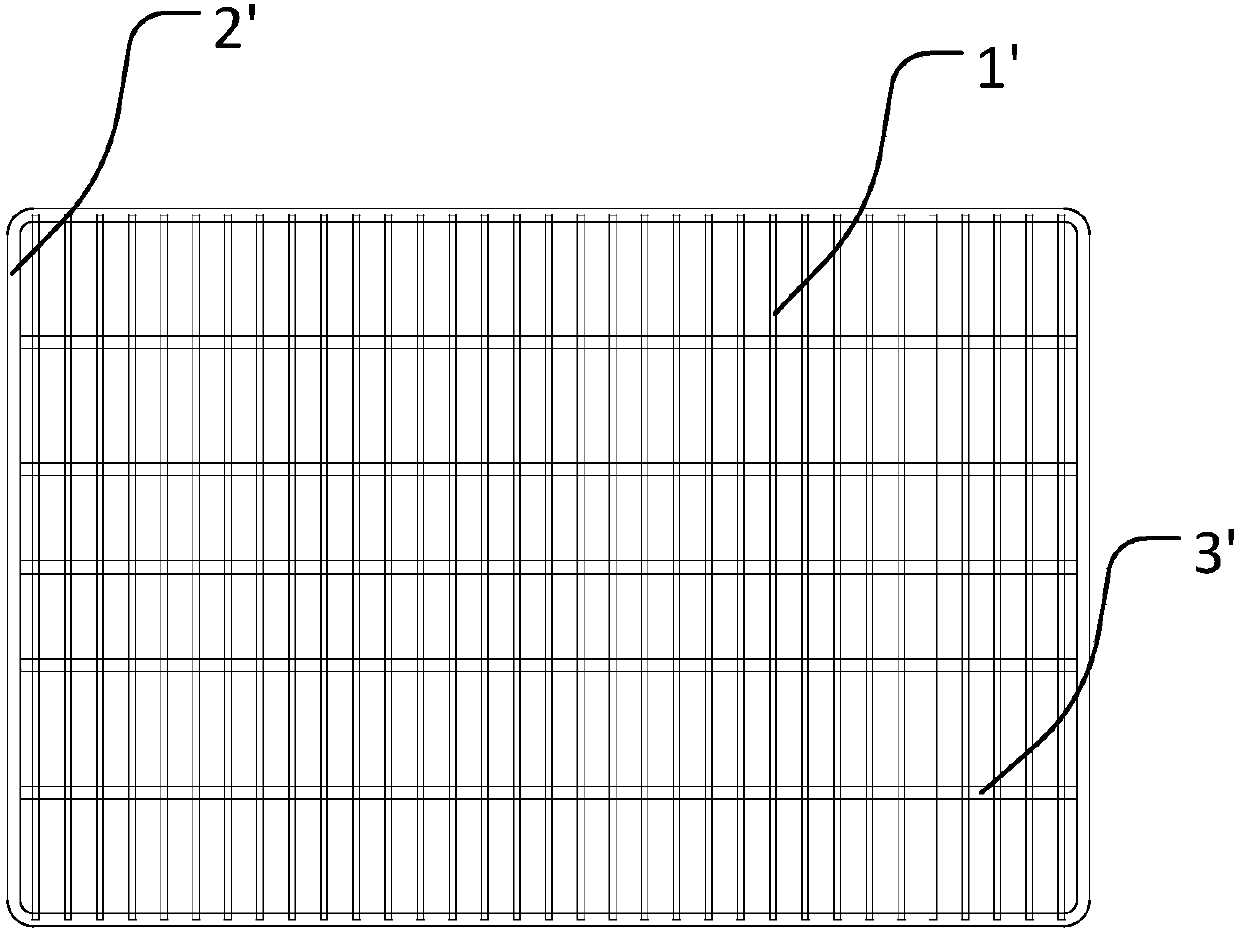

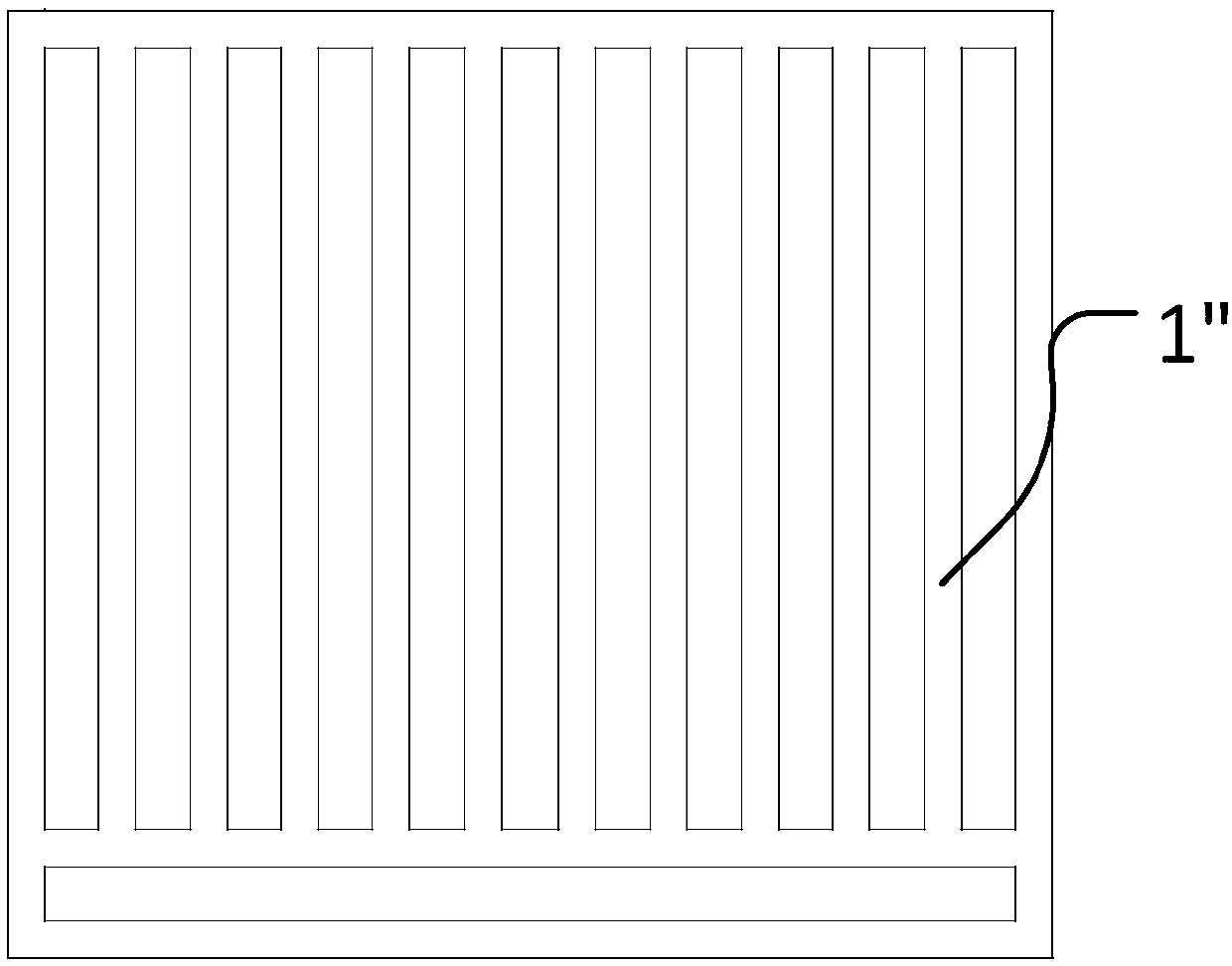

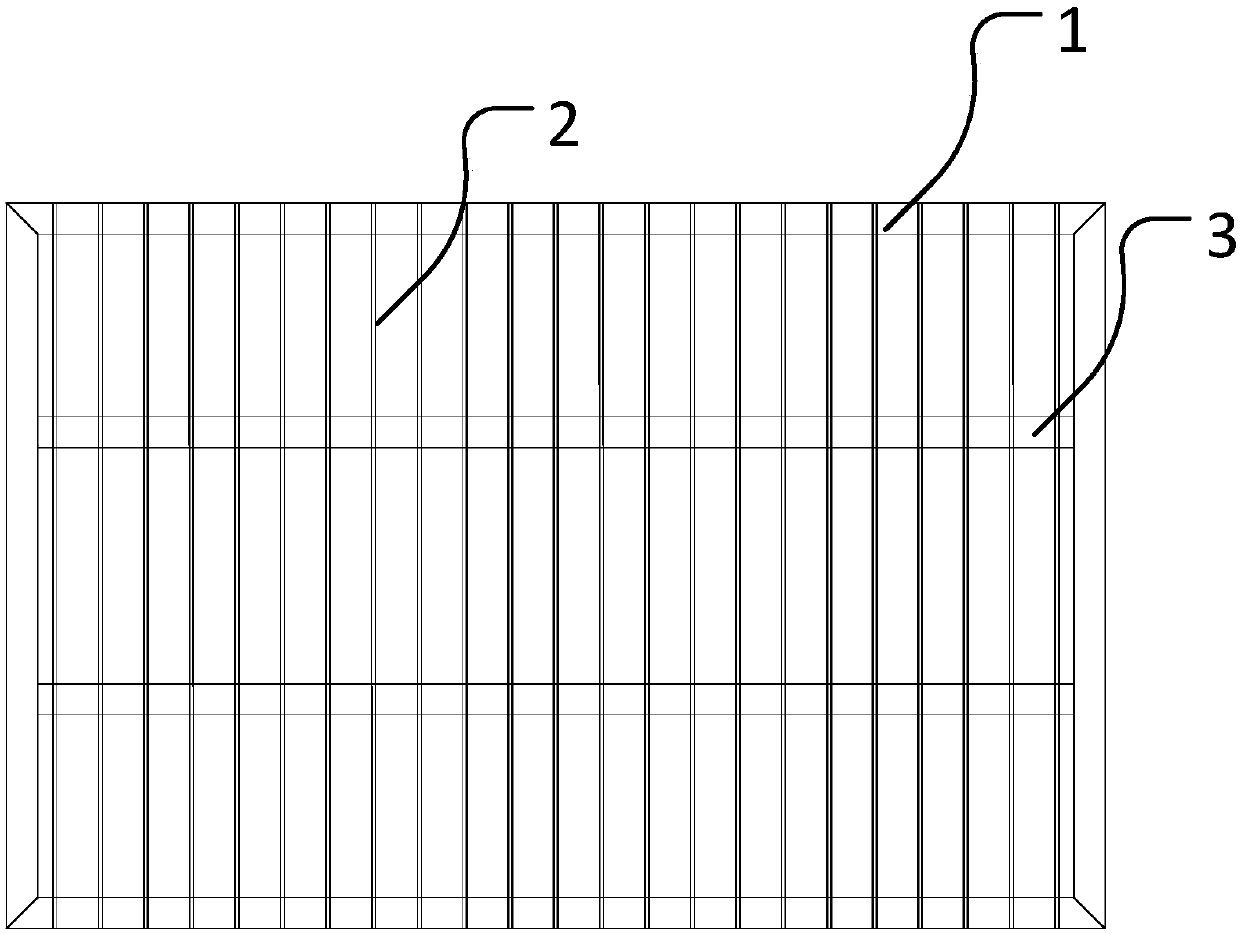

[0046] Such as image 3 As mentioned above, the steam rack disclosed in this embodiment includes a frame 1, a longitudinal beam 2 and a cross beam 3, and the frame 1 and the cross beam 3 together constitute the base of the steam rack. Among them, the frame 1 is connected end-to-end by metal pipes to form a rectangle. Since most of the electrical appliances using the steaming rack in the prior art have a cubic structure, processing the steaming rack into a rectangular shape can be applied to most electrical appliances, and the scope of application is wider. wide. In addition, processing the frame 1 into a rectangle has a simpler processing technology than processing it into a shape such as an irregular shape or a circle. During the processing of the frame 1, the metal tube can be a round tube or a square tube, and the four corners of the rectangle are fixed together by halved welding, which not only can effectively achieve sealing, but also maintains the overall aesthetics of ...

Embodiment 2

[0053] This embodiment discloses a steaming cabinet, and the steaming cabinet is provided with the steaming rack in the first embodiment. Therefore, the production cost of the steamer in this embodiment is lower, the use reliability is higher, and the user experience is better, and the food will not fall due to the low strength of the steaming rack during use.

Embodiment 3

[0055] This embodiment discloses an oven. The oven is provided with the steaming rack in Embodiment 1. The steaming rack of the oven will not be deformed or corroded under high temperature and high pressure, which further improves the durability and service life of the oven. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com