A kind of beneficiation and purification method of low-grade microcrystalline graphite

A technology of microcrystalline graphite and purification method, applied in chemical instruments and methods, flotation, solid separation, etc., can solve the problems of low grade of graphite concentrate and low recovery rate, and achieve short process, reasonable utilization, and enrichment ratio. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A microcrystalline graphite mine in Hunan, the fixed carbon content in the ore is 55.32wt%, the main useful minerals in the ore are graphite, the gangue minerals are mica, quartz and chlorite, and a small amount of montmorillonite and calcite. Small amounts of metal sulfide minerals are pyrite, sphalerite, galena and chalcopyrite, respectively. In addition, it also contains a small amount of apatite, rutile and so on.

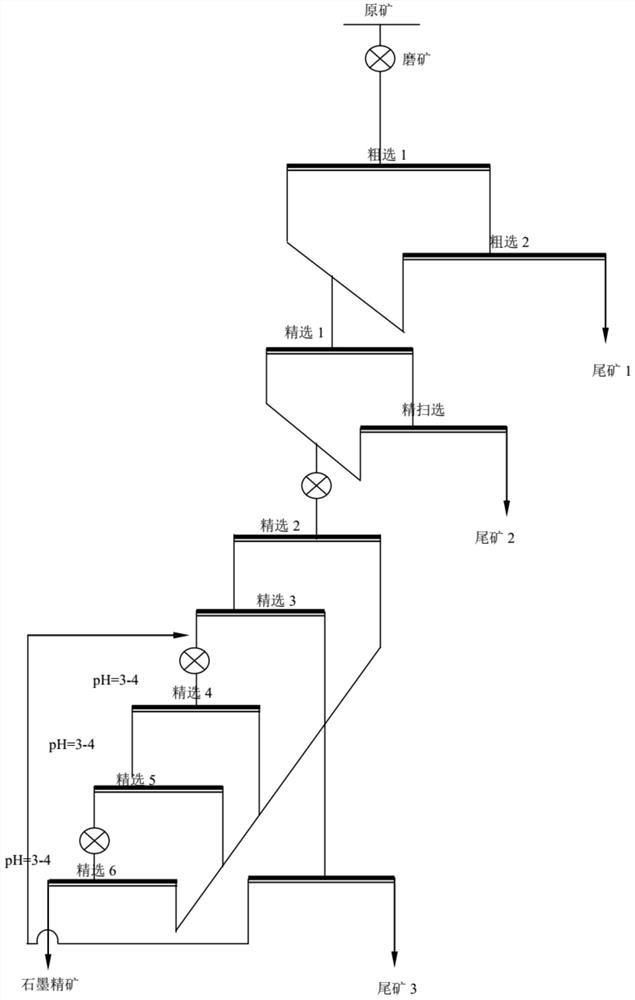

[0025] Under the condition of 72.18% ore grinding fineness, 400g / ton of emulsified kerosene as a collector and 80g / ton of ethyl ether alcohol as a foaming agent are added to the raw ore. The concentrated ore and tailings 2 are obtained through a selection of the ore; the concentrated ore is re-grinded once, the re-grinding concentration is 28%, the grinding fineness -0.037mm content is 88%, and the amount of emulsified kerosene is 30g / ton , The amount of ethyl ether alcohol is 10g / ton, and the selection is carried out twice, with a concentration of 12%,...

Embodiment 2

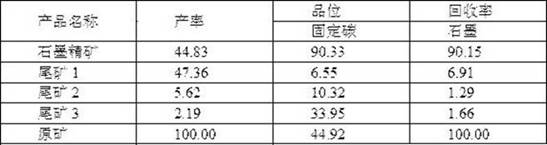

[0029] The raw ore is selected from a microcrystalline graphite mine in Heilongjiang. The fixed carbon content in the ore is 44.92wt%. The main useful mineral in the ore is graphite, and the main gangue minerals are quartz, illite, and muscovite.

[0030] Under the condition of 66.98% grinding fineness, 350g / ton of emulsified kerosene as a collector and 50g / ton of ethyl ether alcohol as a foaming agent are added to the raw ore. Selected ore concentrate and tailings 2 are obtained through a selection of ore; the selected concentrate is re-grinded once, the re-grinding concentration is 30%, the grinding fineness -0.037mm content is 85%, and the amount of emulsified kerosene is 30g / ton , The amount of ethyl ether alcohol is 10g / ton, and the selection is carried out twice, with a concentration of 10%, to obtain the first regrinding concentrate and the first regrinding tailings; the first regrinding Select the concentrated ore for the second regrind, the second regrind concentratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com