Preparation method of nanoring

A nano-ring and nano-scale technology, which is applied in the coupling of optical waveguides, the manufacture of microstructure devices, and the process for producing decorative surface effects. It can solve the problems of high cost, long time consumption, and difficulty in preparing nano-patterns on a large scale. , to achieve low-cost preparation and solve the effect of complex process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

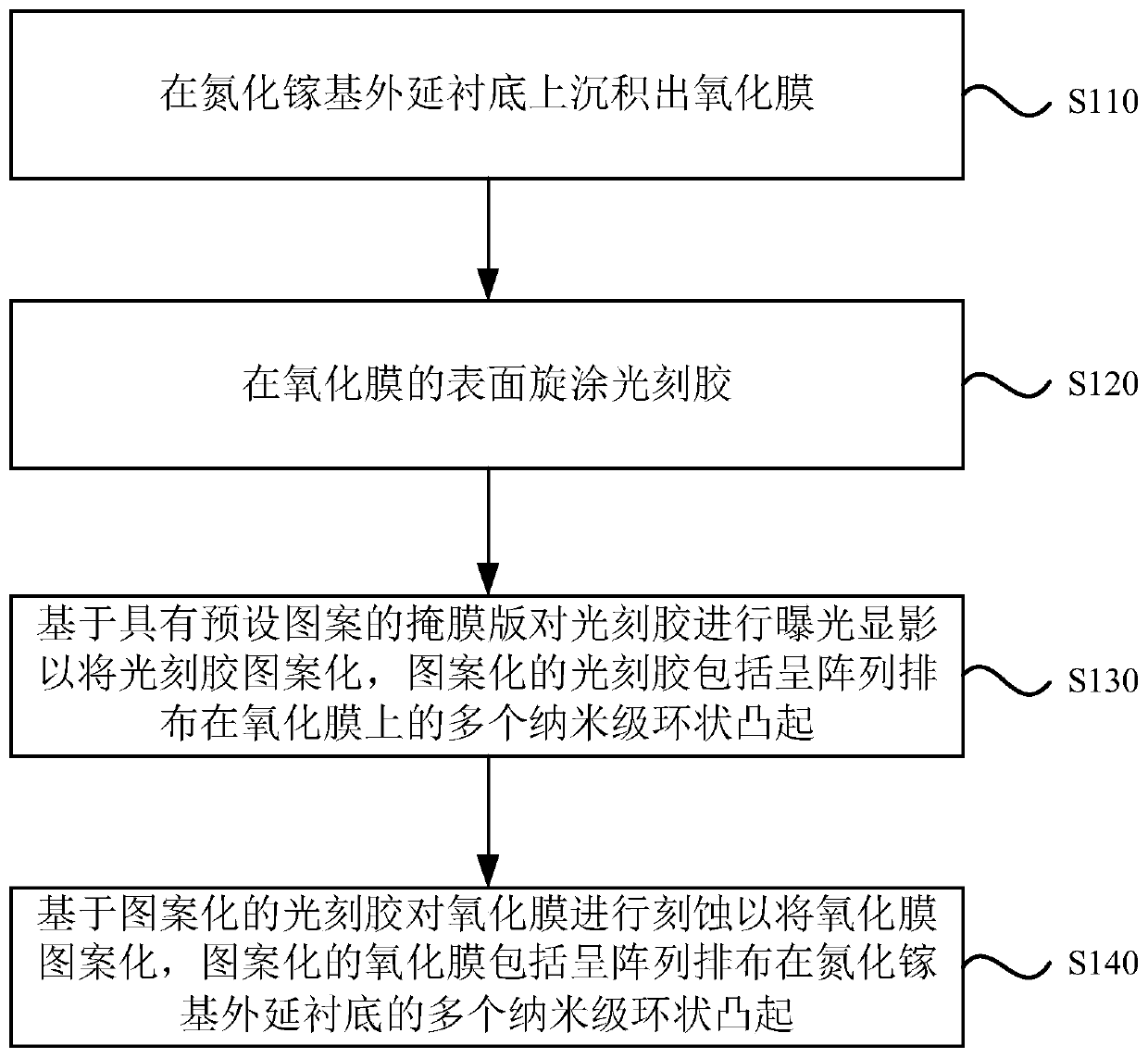

[0048] Such as figure 1 As shown, Embodiment 1 of the present invention provides a method for preparing a nanoring, the method comprising:

[0049] S110, depositing an oxide film on the GaN-based epitaxial substrate.

[0050] S120, spin-coating photoresist on the surface of the oxide film.

[0051] In this embodiment, when preparing gallium nitride-based nanorings, it is first necessary to deposit an oxide film on a gallium nitride-based epitaxial substrate, wherein the gallium nitride-based epitaxial substrate can be a gallium nitride-based LED wafer, consisting of The material of the epitaxial substrate can also include aluminum nitride, indium nitride or other ternary and quaternary alloy materials. Optionally, the plasma-enhanced chemical vapor phase epitaxy (PECVD) method is used to deposit on the gallium nitride-based LED wafer An oxide film is produced, wherein the oxide film can be a silicon dioxide film layer. After the oxide film is deposited, a photoresist needs t...

Embodiment 2

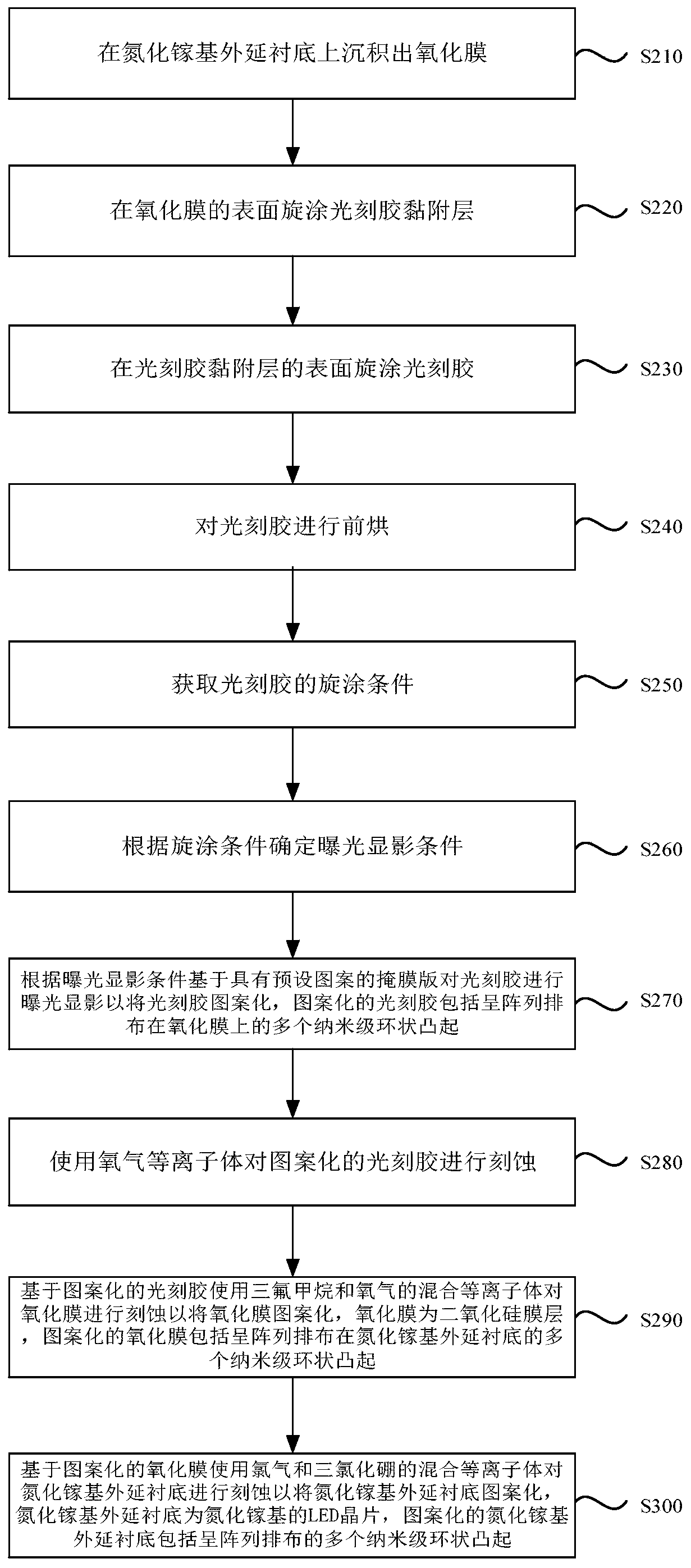

[0058] Such as figure 2 As shown, Embodiment 2 of the present invention provides a method for preparing nanorings. Embodiment 2 of the present invention is a further explanation on the basis of Embodiment 1 of the present invention. The method includes:

[0059] S210, depositing an oxide film on the GaN-based epitaxial substrate.

[0060] S220, spin coating a photoresist adhesion layer on the surface of the oxide film.

[0061] S230. Spin-coat photoresist on the surface of the photoresist adhesion layer.

[0062] S240, pre-baking the photoresist.

[0063] In this embodiment, before the photoresist is spin-coated on the surface of the oxide film, a photoresist adhesion layer needs to be spin-coated on the surface of the oxide film to increase the adhesion between the photoresist and the surface of the oxide film, and then the photoresist The surface of the adhesion layer is spin-coated with photoresist. After the photoresist is spin-coated, the photoresist needs to be pre-b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com