Industrial production system for producing high-silicon strip with magnetron sputtering continuous two-sided codeposition process

A magnetron sputtering and production system technology, applied in sputtering coating, metal material coating process, ion implantation plating, etc., to achieve high work efficiency and easy control of process parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

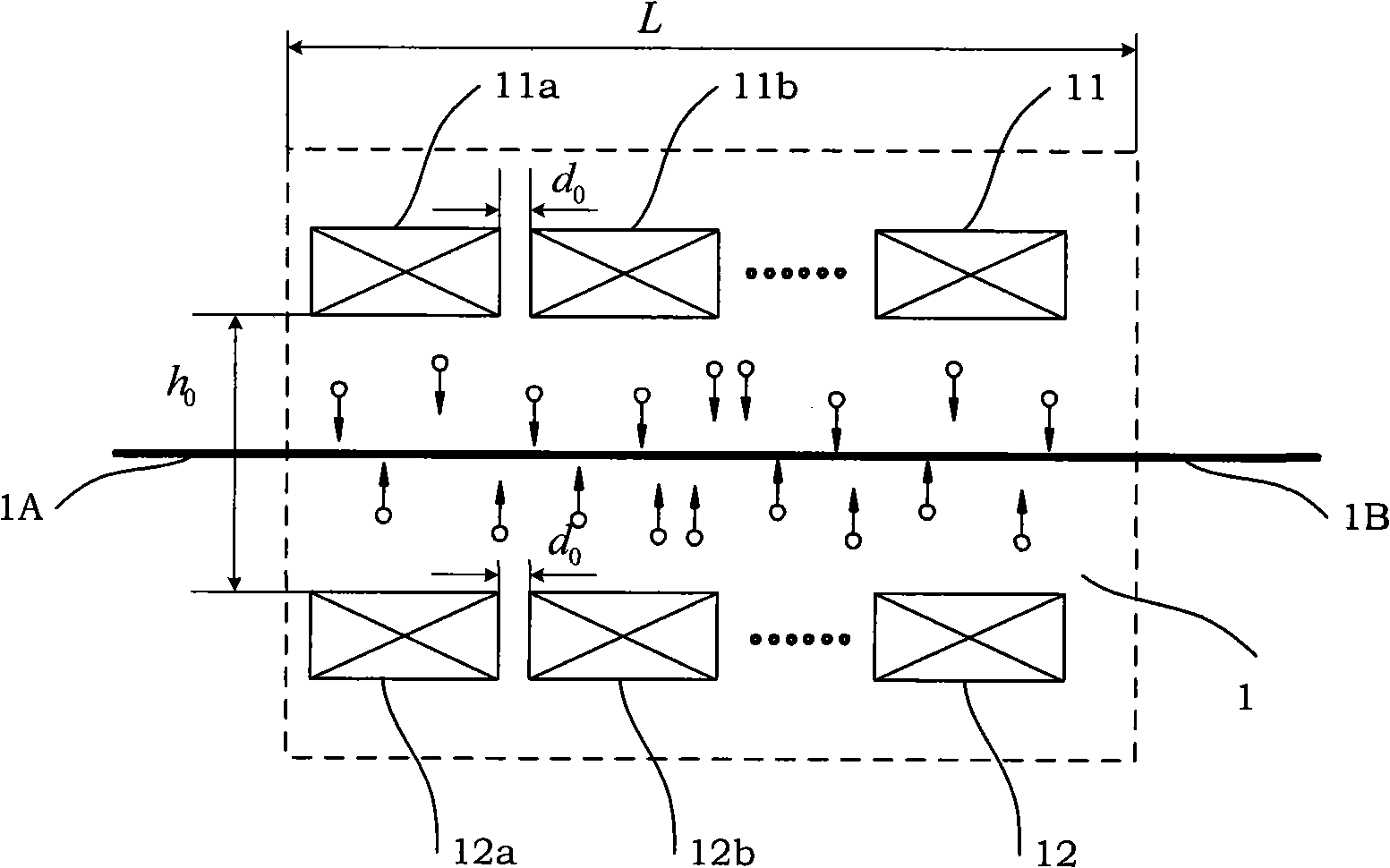

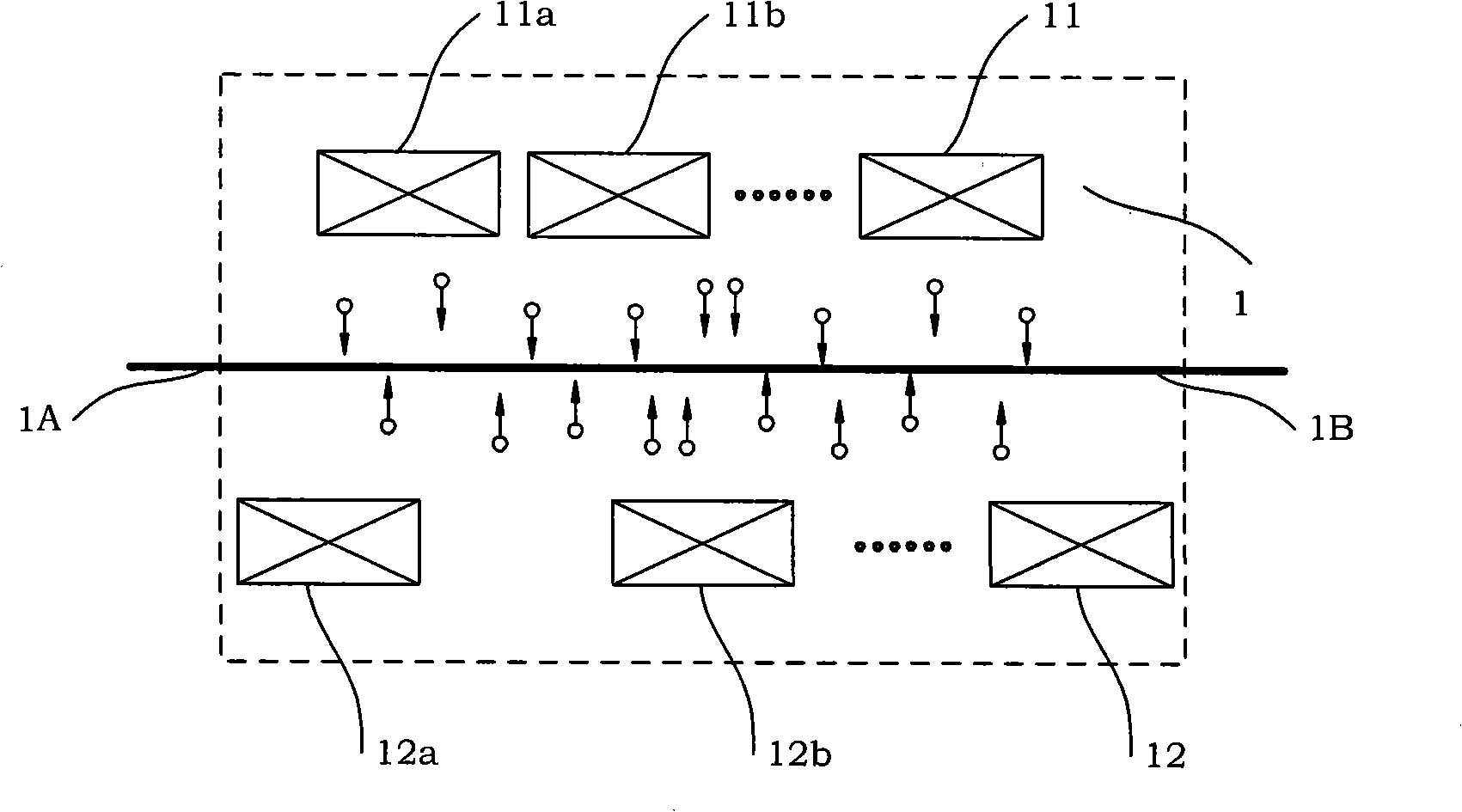

[0069] Fe-6.5wt% Si high-silicon steel strip is prepared on a 0.20mm thick Fe-3.0wt% Si low-silicon steel strip

[0070] A silicon material with a purity of 99.9% was deposited on the upper and lower sides of a 0.20mm thick Fe-3.0wt%Si low silicon steel strip, and the thickness of the deposited silicon material was 15 μm.

[0071] The conditions for the industrial production of high silicon steel strip by magnetron sputtering double-sided co-deposition are as follows:

[0072]

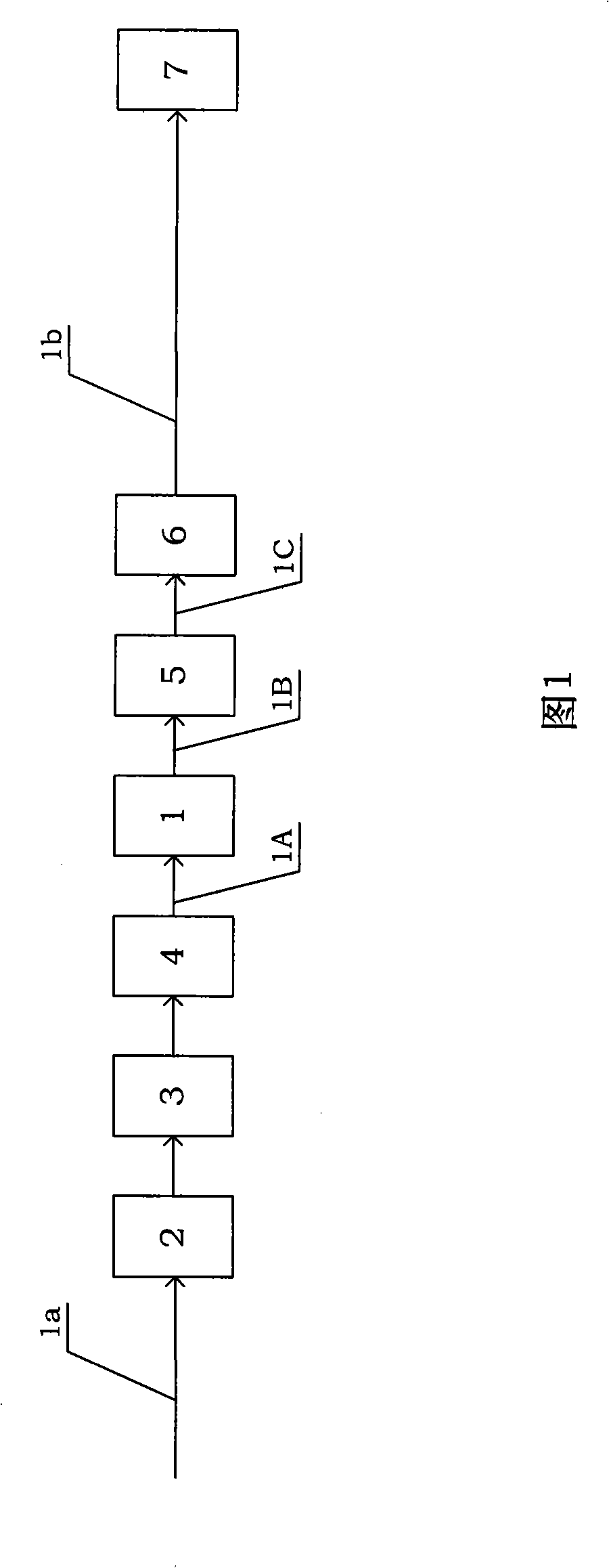

[0073] The processing steps of magnetron sputtering double-sided co-deposition for industrial production of high silicon steel strip include:

[0074] Step 1: Prepare the silicon target

[0075] The target material is polysilicon, the thickness is 6mm×the length is 300mm×the width is 300mm, and the size of the target material is compatible with the size of the boss 161 set in the cathode cap 106;

[0076] Step 2: Install the silicon steel belt

[0077] One end of the 0.20mm thick Fe-3.0wt%Si low-silicon ...

Embodiment 2

[0085] Fe-6.5wt%Si high-silicon steel strip prepared on 35WW270 low-silicon steel strip

[0086] A silicon material with a purity of 99.9% was deposited on the upper and lower sides of the 35WW270 low silicon steel strip, and the thickness of the deposited silicon material was 20 μm.

[0087] The conditions for the industrial production of high silicon steel strip by magnetron sputtering double-sided co-deposition are as follows:

[0088]

[0089] The processing steps of magnetron sputtering double-sided co-deposition for industrial production of high silicon steel strip include:

[0090] Step 1: Prepare the silicon target

[0091] The target material is polysilicon, the thickness is 6mm×the length is 300mm×the width is 300mm, and the size of the target material is compatible with the size of the boss 161 set in the cathode cap 106;

[0092] Step 2: Install the silicon steel belt

[0093] Install one end of the 35WW270 low-silicon steel strip on the uncoiler 2, and install the o...

Embodiment 3

[0101] High-silicon steel belt made on 35WW440 low-silicon steel belt

[0102] Silicon material with a purity of 99.9% was deposited on the upper and lower sides of the 35WW440 low-silicon steel strip, and the thickness of the deposited silicon material was 20 μm.

[0103] The conditions for the industrial production of high silicon steel strip by magnetron sputtering double-sided co-deposition are as follows:

[0104]

[0105] The processing steps of magnetron sputtering double-sided co-deposition for industrial production of high silicon steel strip include:

[0106] Step 1: Prepare the silicon target

[0107] The target material is polysilicon, the thickness is 6mm×the length is 300mm×the width is 300mm, and the size of the target material is compatible with the size of the boss 161 set in the cathode cap 106;

[0108] Step 2: Install the silicon steel belt

[0109] Install one end of the 35WW440 low-silicon steel strip on the uncoiler 2, and install the other end on the coil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com