Microstrip transmission device and preparation method

A technology of microstrip transmission and microstrip transmission line, which is applied in the direction of waveguide devices, electrical components, waveguides, etc., can solve the application limitations of high-frequency signal shielding transmission, cannot achieve miniaturization production requirements, and cannot achieve isolation well Transmission and other issues, to achieve the effect of controllable hole wall roughness, high-performance transmission satisfaction, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

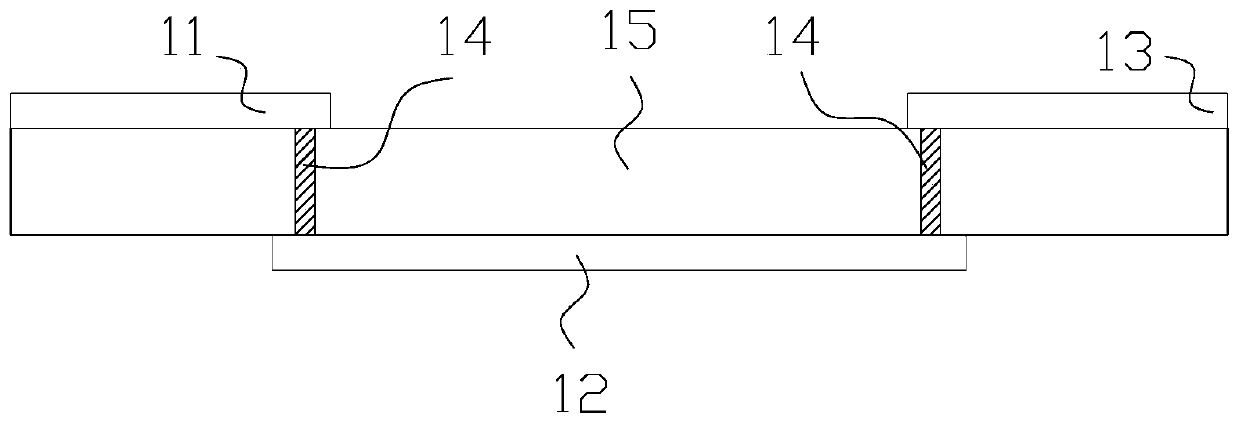

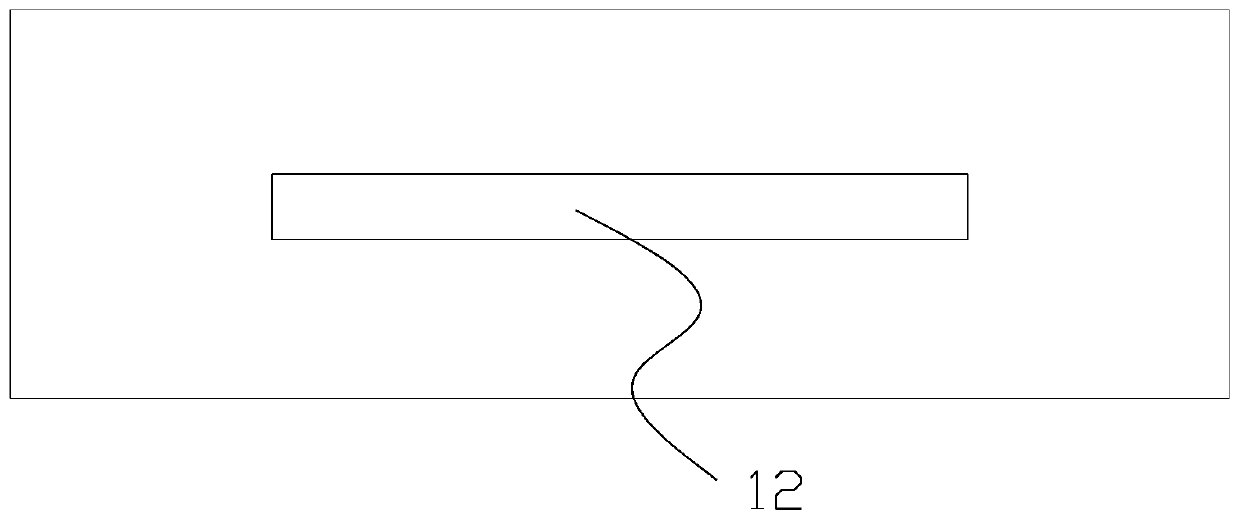

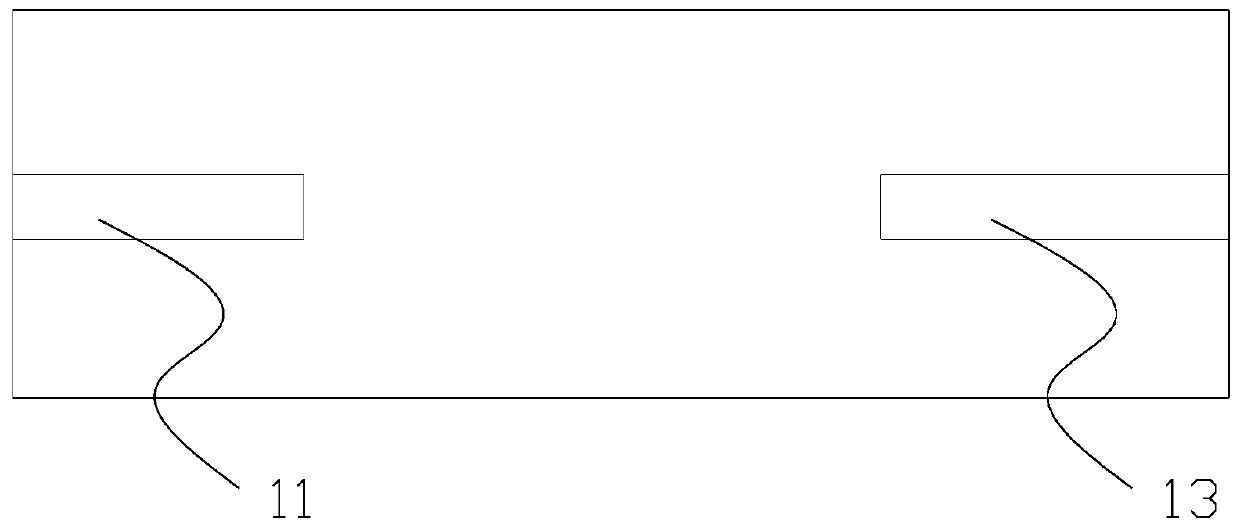

[0034] figure 1 It is a structural schematic diagram of the prior art, which has no isolation holes. figure 2 show figure 1 A schematic view of the state of looking up in the prior art shown. figure 1 Among them, 11 is section A of the microstrip transmission line, 12 is section B of the microstrip transmission line, 13 is section C of the microstrip transmission line, 14 is a metallized via hole, and 15 is a substrate.

[0035] image 3 It is a structural schematic diagram of the present invention, Figure 4 For looking up state. 41 is section A of the microstrip transmission line, 42 is section B of the microstrip transmission line, 43 is section C of the microstrip transmission line, 44 is a metallized via hole, 45 is a glass substrate, and 46 is a shielding hole. Figure 4 It shows the looking up state, and the shielding holes are arranged on both sides of the microstrip transmission line. Since the shielding hole is a metallized through hole, see the top view Fig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com