Silicone-rubber porous material array with elastic hollow fibers and preparing method thereof

A hollow fiber and porous material technology, applied in fiber processing, hollow filament manufacturing, fiber chemical characteristics, etc., can solve problems such as high cost and complex process, and achieve good molding, high degree of continuity, good compression and self-recovery ability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

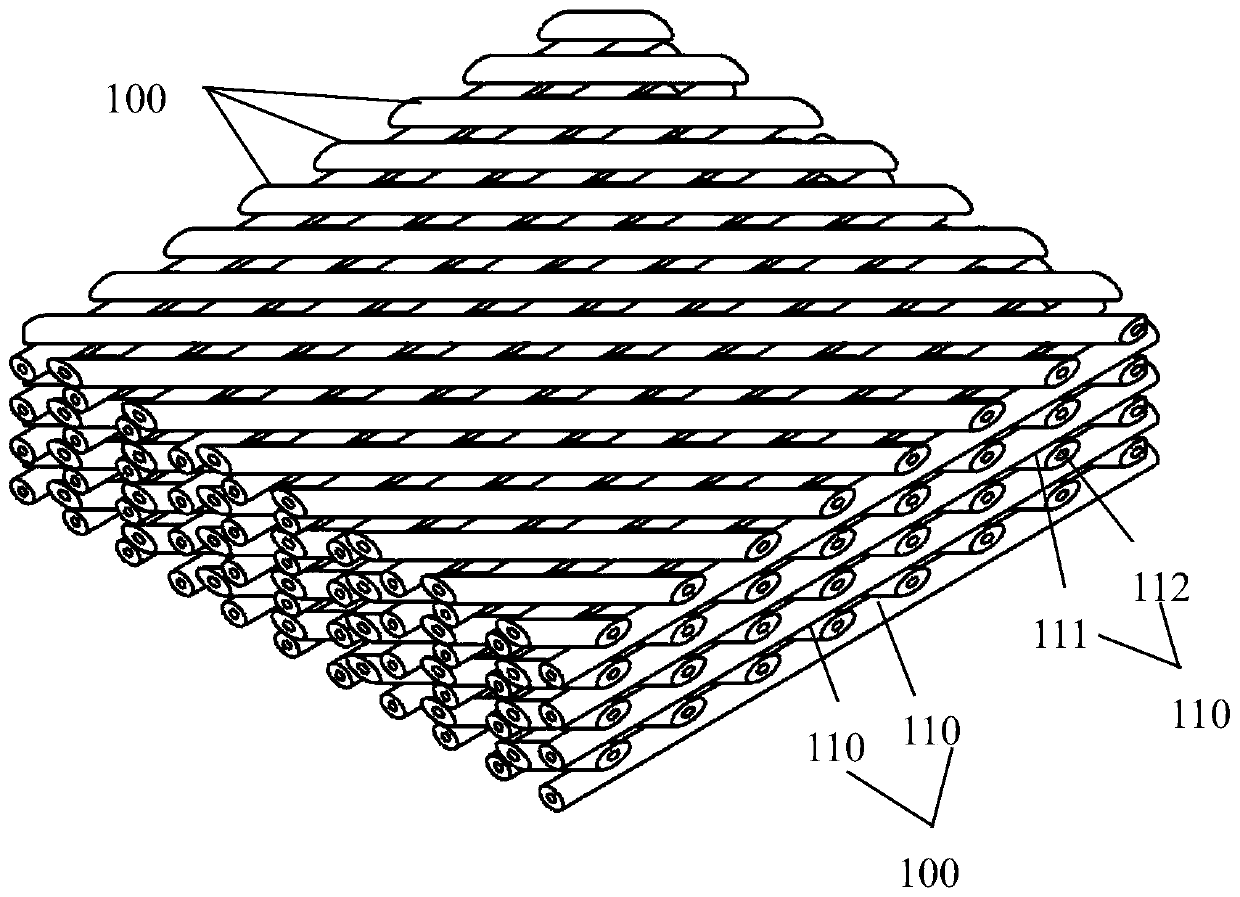

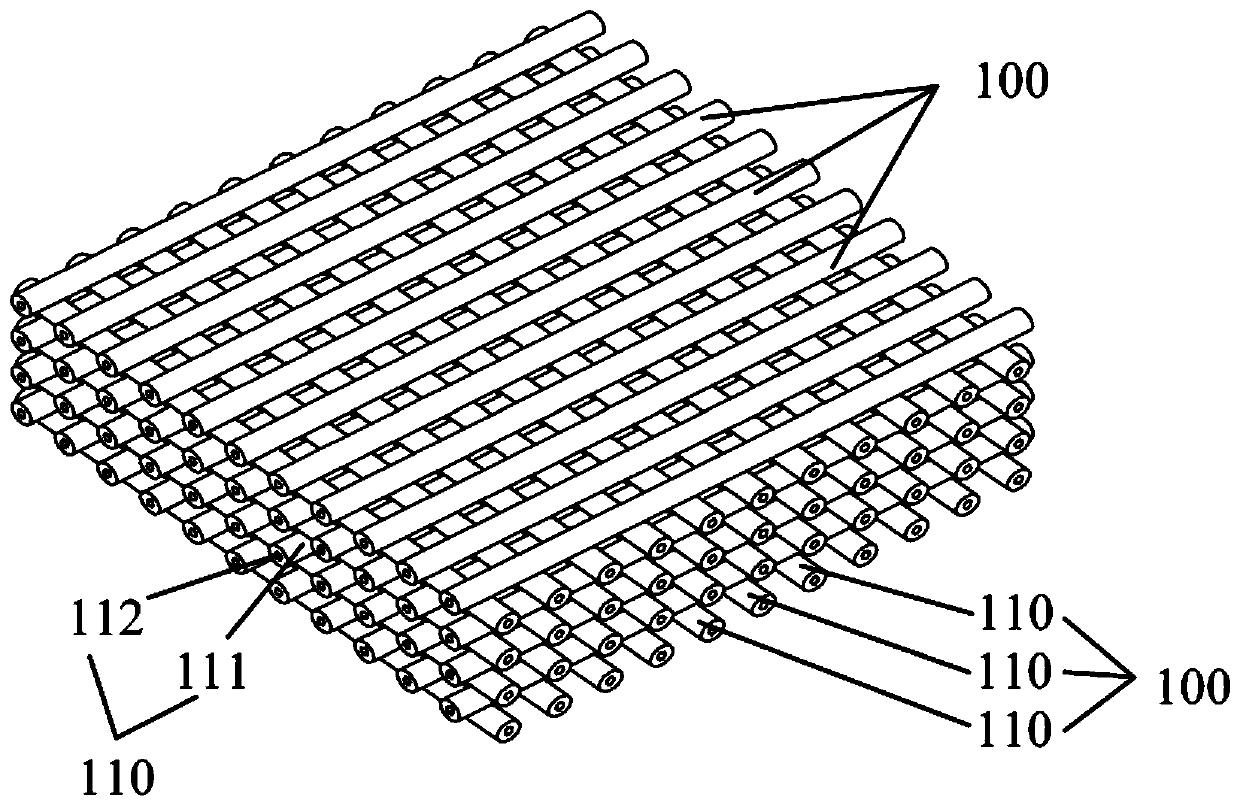

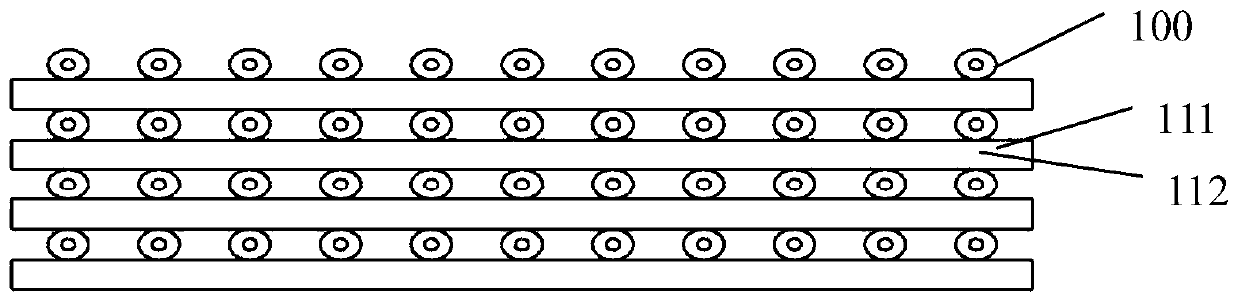

[0033] A silicone rubber porous material array with elastic hollow fibers, the silicone rubber porous material array of elastic hollow fibers includes: 8 layers of hollow fiber array structures 100, each layer of hollow fiber array structures 100 includes a plurality of elastic hollow fibers arranged in parallel Fiber 110, the elastic hollow fibers of adjacent two layers of hollow fiber array structure 100 cross each other at 45°, each elastic hollow fiber 110 includes an elastic shell 111 and an air layer 112 in the shell, the air layer 112 forms a buffer airbag array , the elastic shell 111 forms the conformal shell of the cushioning airbag.

[0034] A preparation method of a silicone rubber porous material array with elastic hollow fibers, comprising the following steps:

[0035] (1) Submerge the silicon wafer in an ethanol solution with a volume fraction of 1% fluorinated silane, let it stand for 24 hours, take out the silicon wafer and dry it as a substrate;

[0036] (2)...

Embodiment 2

[0046]A silicone rubber porous material array with elastic hollow fibers, the silicone rubber porous material array of elastic hollow fibers includes: 8 layers of hollow fiber array structures 100, each layer of hollow fiber array structures 100 includes a plurality of elastic hollow fibers arranged in parallel Fiber 110, the elastic hollow fibers of adjacent two layers of hollow fiber array structure 100 cross each other at 90°, each elastic hollow fiber 110 includes an elastic shell 111 and an air layer 112 in the shell, the air layer 112 forms a buffer airbag array , the elastic shell 111 forms the conformal shell of the cushioning airbag.

[0047] A preparation method of a silicone rubber porous material array with elastic hollow fibers, comprising the following steps:

[0048] (1) Submerge the silicon wafer in an ethanol solution with a volume fraction of 1% fluorinated silane, let it stand for 24 hours, take out the silicon wafer and dry it as a substrate;

[0049] (2) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com