Antioxidant absorbent and preparation method thereof

An absorbent and anti-oxidation technology, which is applied in metal processing equipment, coating, transportation and packaging, etc., can solve the problems of low oxidation resistance of carbonyl iron powder, difficulty in resisting long-term high temperature application, and the coating layer is not dense enough. Achieving the effects of good anti-oxidation performance, reduced preparation cost, good temperature resistance and

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

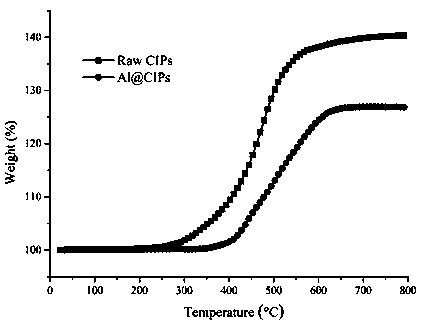

Image

Examples

Embodiment 1

[0051] This embodiment proposes an anti-oxidant carbonyl iron / aluminum mixed powder absorbent, which is composed of 91 wt.% carbonyl iron powder and 9 wt.% aluminum powder.

[0052] This embodiment also proposes a method for preparing the anti-oxidation carbonyl iron / aluminum mixed powder absorbent, the specific process is:

[0053] Step S1: Preparation of carbonyl iron / aluminum mixed powder with iron / aluminum alloy layer:

[0054] Step S11: Weigh 91wt.% of the carbonyl iron powder with an average particle size of 4μm and 9wt.% of the aluminum powder with an average particle size of 50nm according to the mass fraction to obtain a carbonyl iron / aluminum mixed powder, and put the carbonyl iron / aluminum mixed powder Put into the zirconia ball mill tank;

[0055] Step S12, adding zirconia grinding balls into the zirconia ball milling tank, and the mass ratio of the zirconia grinding balls to the carbonyl iron / aluminum mixed powder balls is 10:1;

[0056] Step S13, adding an appropriate amo...

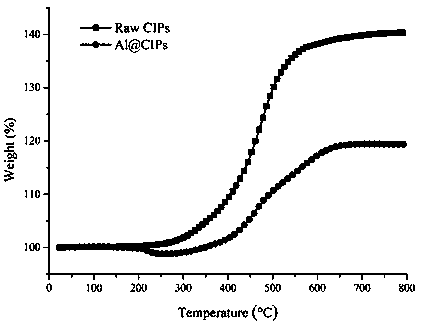

Embodiment 2

[0065] This embodiment proposes an anti-oxidant carbonyl iron / aluminum mixed powder absorbent, which is composed of carbonyl iron powder with a mass fraction of 85 wt.% and aluminum powder with a mass fraction of 15 wt.%.

[0066] This embodiment also proposes a method for preparing the anti-oxidation carbonyl iron / aluminum mixed powder absorbent, the specific process is:

[0067] Step S1: Preparation of carbonyl iron / aluminum mixed powder with iron / aluminum alloy layer:

[0068] Step S11, weighing 85wt.% of carbonyl iron powder with an average particle size of 6μm and 15wt.% of aluminum powder with an average particle size of 80nm according to the mass fraction to obtain carbonyl iron / aluminum mixed powder, and put the carbonyl iron / aluminum mixed powder Put it into the nylon ball mill tank;

[0069] Step S12, adding stainless steel grinding balls into the nylon ball milling tank, and the mass ratio of the stainless steel grinding balls to the carbonyl iron / aluminum mixed powder ball...

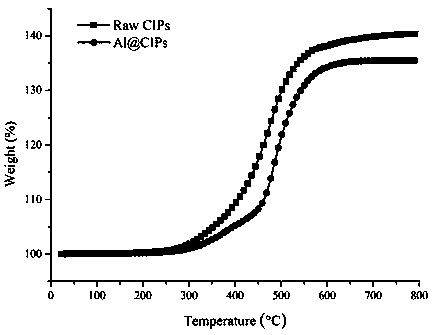

Embodiment 3

[0079] This embodiment proposes an anti-oxidant carbonyl iron / aluminum mixed powder absorbent, which is composed of 97 wt.% carbonyl iron powder and 3 wt.% aluminum powder.

[0080] This embodiment also proposes a method for preparing the anti-oxidation carbonyl iron / aluminum mixed powder absorbent, the specific process is:

[0081] Step S1: Preparation of carbonyl iron / aluminum mixed powder with iron / aluminum alloy layer:

[0082] Step S11, weigh 97wt.% of the carbonyl iron powder with an average particle size of 1μm and 3wt.% of the aluminum powder with an average particle size of 20nm according to the mass fraction to obtain a carbonyl iron / aluminum mixed powder, and put the carbonyl iron / aluminum mixed powder Put it into the PTFE ball mill tank;

[0083] Step S12, adding alumina grinding balls into the polytetrafluoroethylene ball milling tank, and the mass ratio of the alumina grinding balls to the carbonyl iron / aluminum mixed powder balls is 5:1;

[0084] Step S13, adding an appr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com