Straw non-woven fabric and production method of straw non-woven fabric

A technology of non-woven fabrics and production methods, applied in the directions of non-woven fabrics, textiles and paper making, etc., to achieve the effects of simple operation, good performance and good water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

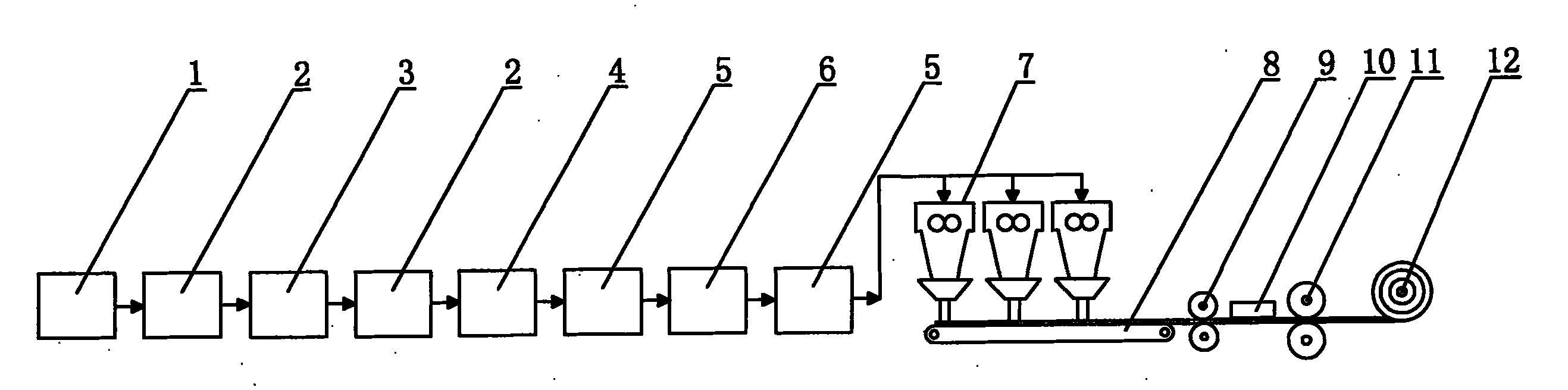

[0019] In the figure: the straw 1 is the grass stem of the plant, and the straw 1 is piled on the top of the conveying mesh belt 2, and the conveying mesh belt 2 is connected with the grass inlet of the straw chopper 3, and the chopped straw 1 fiber is conveyed The net is transported to the primary fiber splitter 4, and then transported to the fine fiber splitter 6 through the fan 5 and the conveying pipe, and then the straw 1 fiber is sent to the air chamber 7 by the conveying pipe of the fan pipe, and the air chamber 7 is equipped with Airflow device: The fibers are in a uniform suspension state, so that the straw 1 fiber slowly settles on the polyester net 8, and the polyester net 8 is continuously pushed forward, and enters a pair of upper and lower pre-rollers 9 for pre-pressing. An infrared heater 10 is installed next to the pre-roller 9 for heating, so that the water in the fiber web is evaporated, and then heated and rolled by a pair of hot rollers 11, so that the fiber...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com