Refined cost analysis system and method

A cost analysis and refinement technology, applied in the field of real-time cost analysis, can solve problems such as high product prices, low product prices, and long accounting cycles, and achieve the effects of reducing costs, improving quality, and optimizing the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

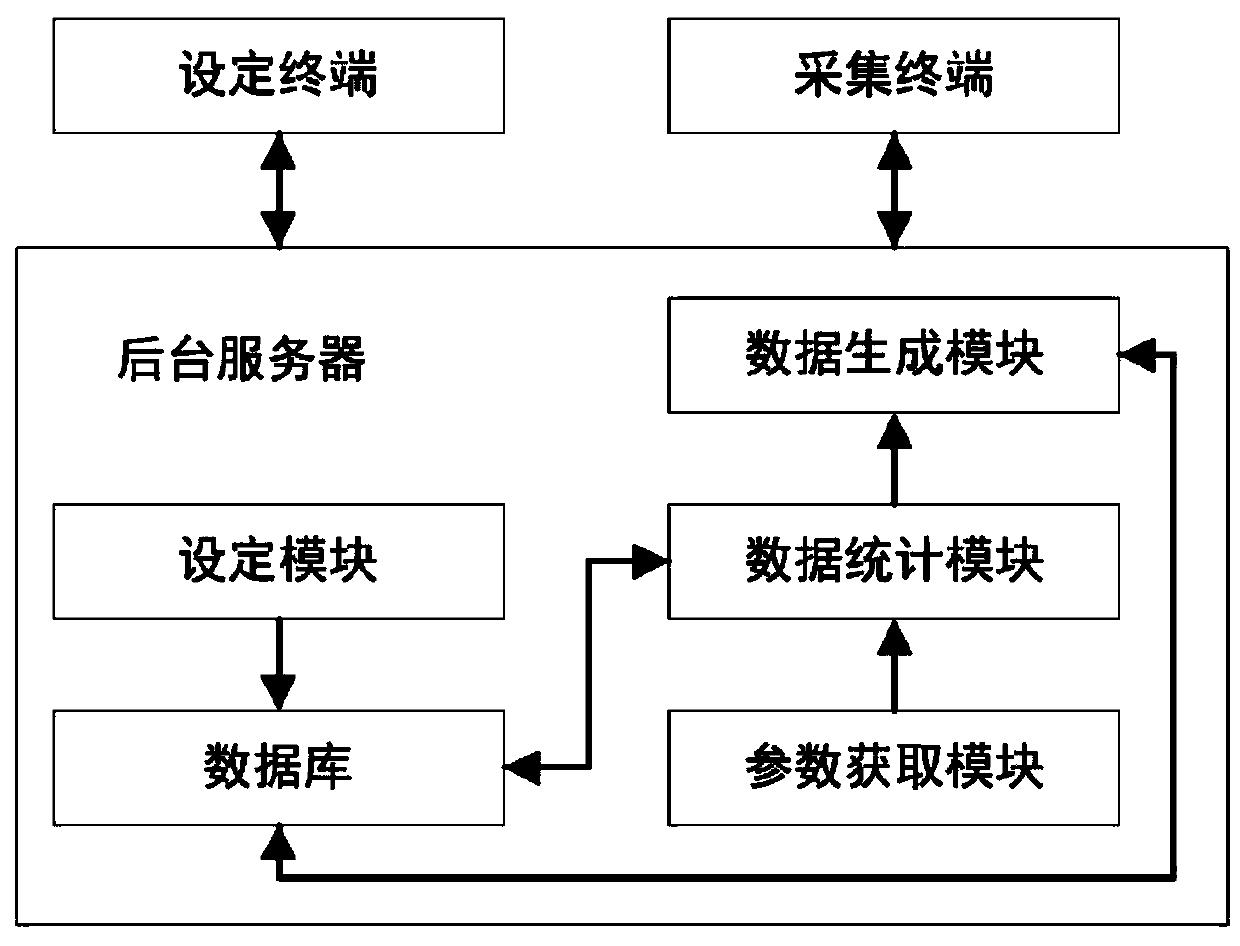

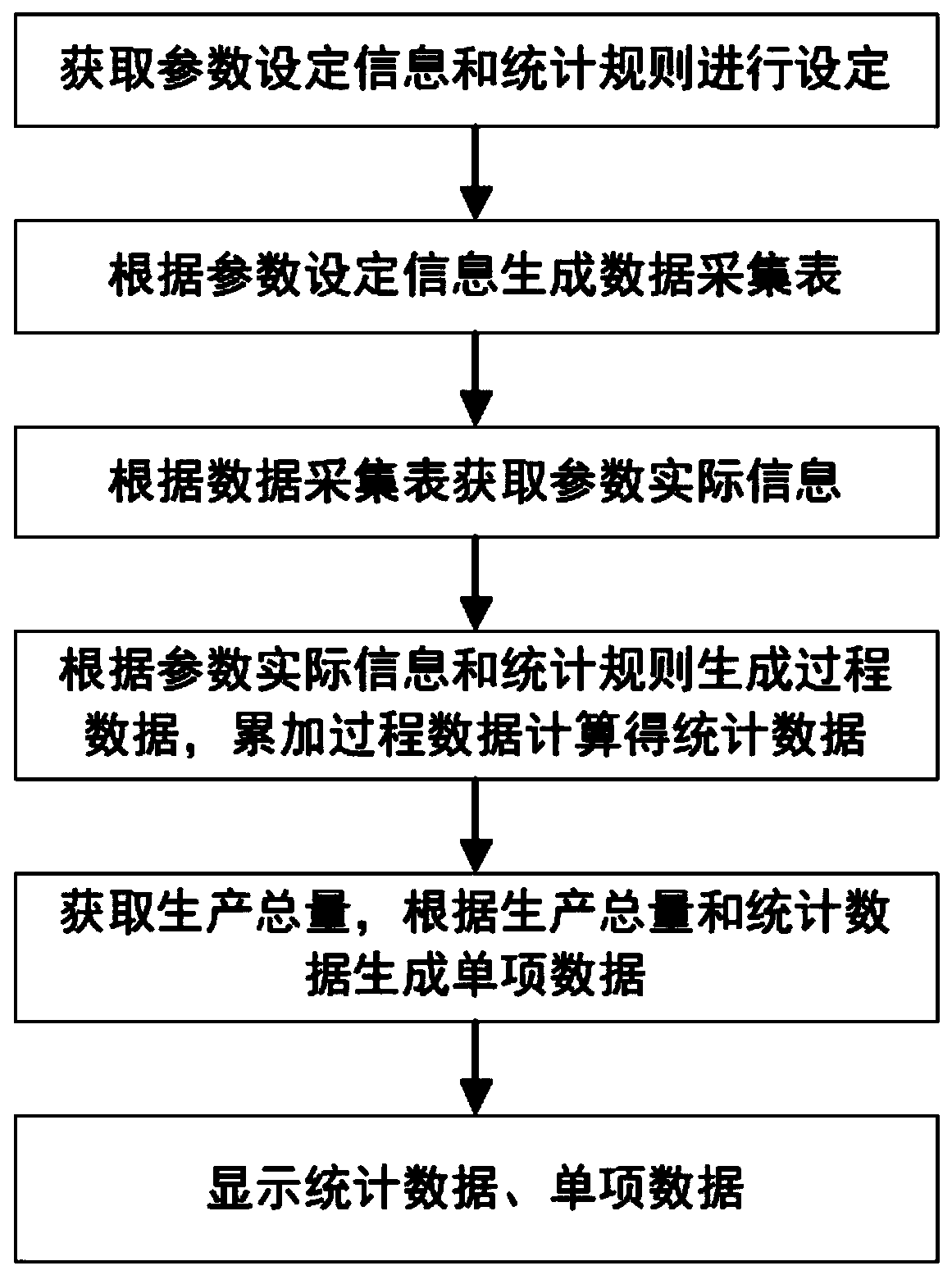

[0051] Refined cost analysis system, as attached figure 1 As shown, it includes a setting terminal, a collection terminal and a background server. The background server includes a database, a setting module, a parameter acquisition module, a data statistics module and a data generation module. Quantity, that is, the number of products that can be shipped out of the warehouse. There are three ways to obtain the total production volume: one is that the data collector collects the total production volume while collecting the actual parameter information through the collection terminal; the other is that the production process is a fully automated production line, and the production volume can be automatically obtained through the production line , and the third is to install sensors on the production line to collect the total production volume through the sensors. In this embodiment, the first method is used to obtain the total production volume and store the total production vol...

Embodiment 2

[0065] In addition to the real-time grasp of the daily cost of a single product in the production process, managers should also grasp the changing trend of the cost of a single product and analyze the changing trend of the cost of a single product so as to reduce costs while ensuring quality. Create greater profits.

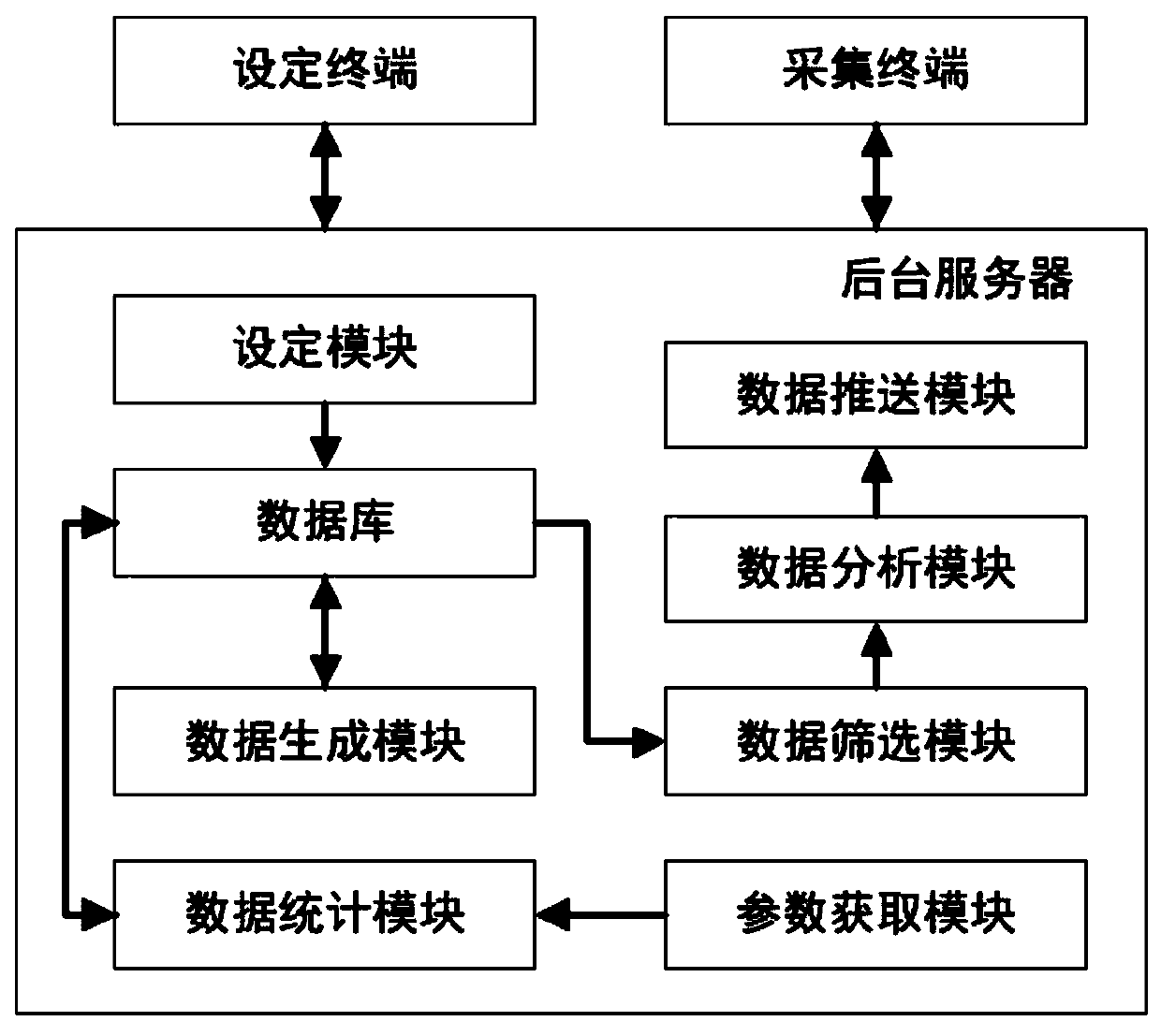

[0066] The difference between this embodiment and Embodiment 1 is that the background server also includes a data screening module and a data analysis module, which mark the storage time while storing individual data, process data, statistical data and actual parameter information.

[0067] The setting terminal is also used to obtain self-optimization signals and analysis quantities, and send them to the background server. After receiving the self-optimization signal and the analysis quantity, the data screening module is used to obtain a number of single items of data that are the same as the analysis quantity from the database in reverse chronological order acc...

Embodiment 3

[0075] In manufacturing enterprises, there is often more than one production line for the same product, and the managers of different production lines are different, and the data of the production process are also different. Therefore, in addition to analyzing the production data of the production lines they manage, managers should also analyze the production data of other production lines, and learn from the production experience of production lines with excellent production data. Take each production line as a production group, and each production line has a unique production group class, that is, a serial number.

[0076] The difference between this embodiment and Embodiment 2 is that: image 3 As shown, the setting terminal is also used to obtain comparative optimization signals and analysis groups, and send them to the background server. The data screening module is used to obtain a number of individual data of the corresponding production group from the database accordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com