Transmission Mechanism and Tilt Rotor UAV

A transmission mechanism and transmission gear technology, applied in the field of drones, can solve problems such as easy bending and damage of lines, large gyro effect, safety accidents, etc., and achieve the effect of reducing impact, small gyro effect, and avoiding line failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

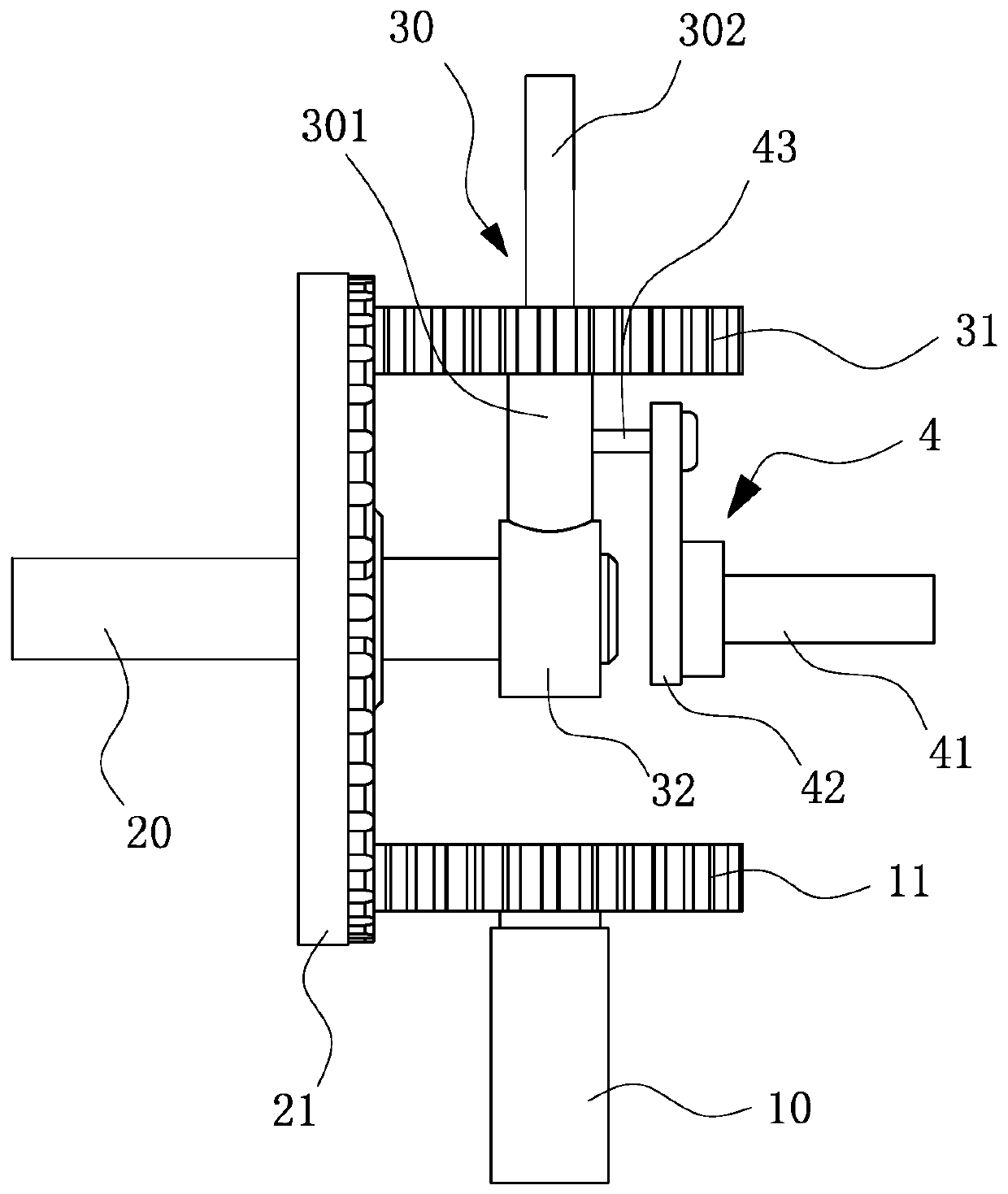

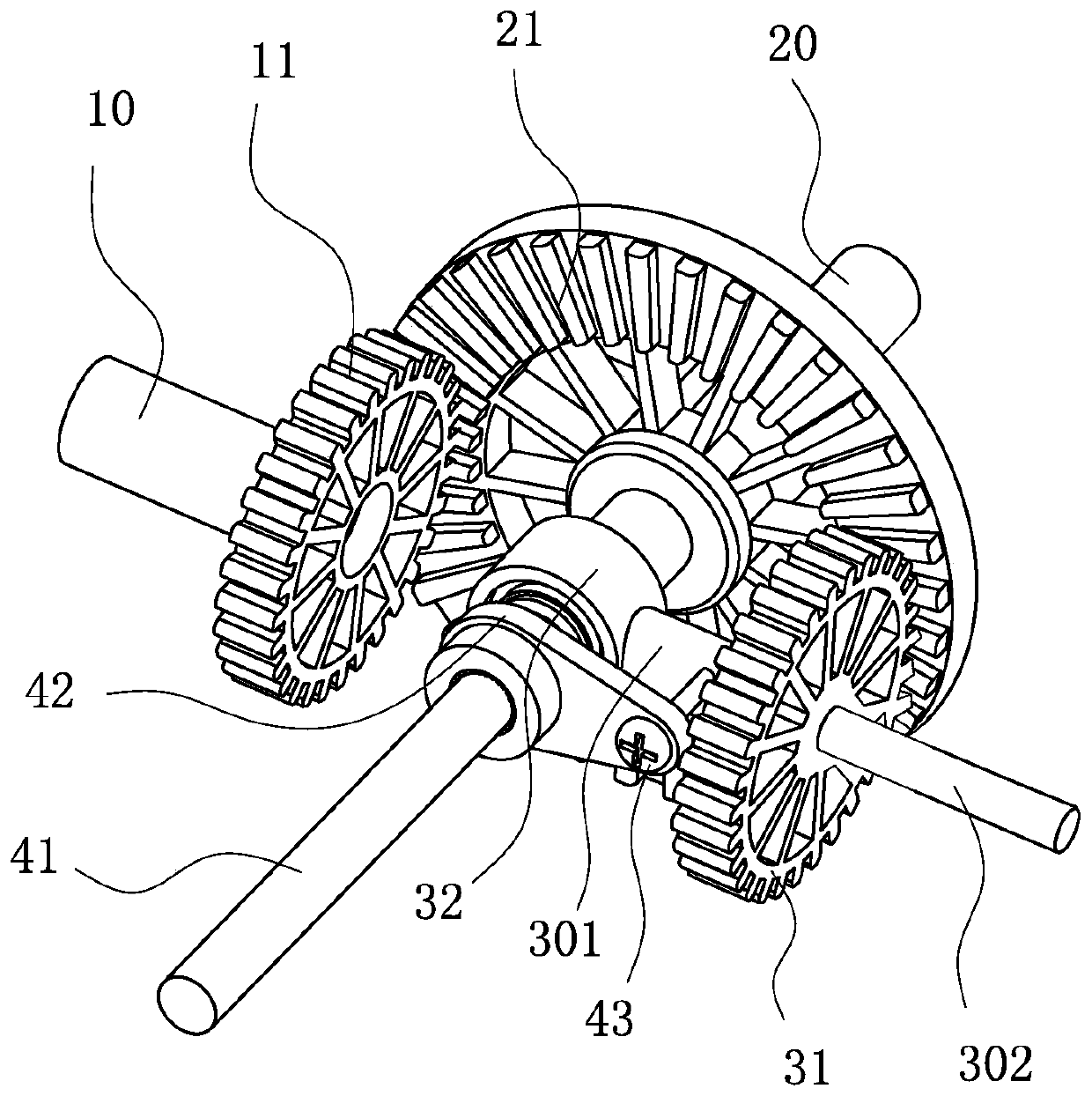

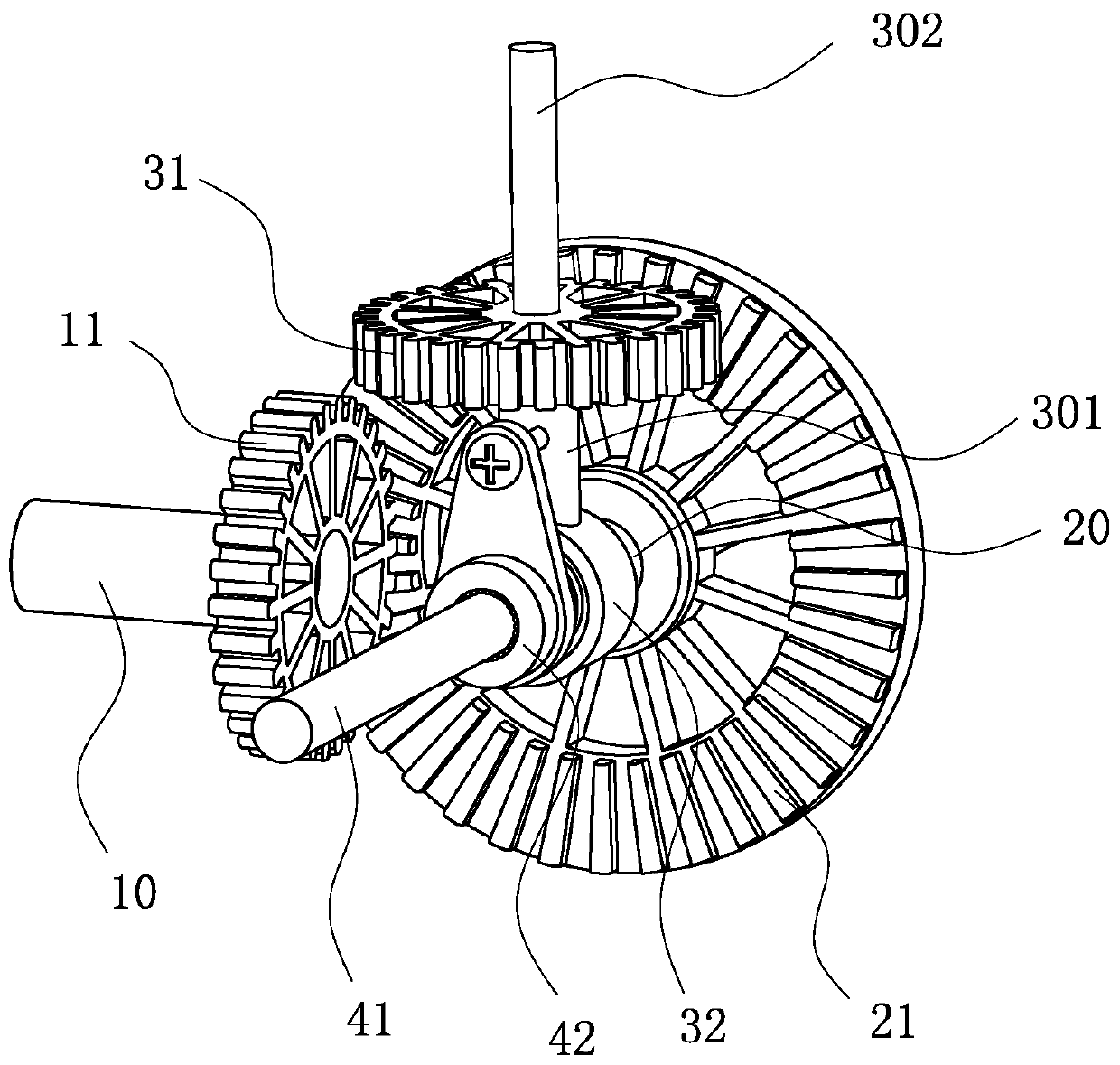

[0030] like figure 1 , figure 2 as well as image 3 Commonly shown, a transmission mechanism includes a first shaft 10 and a second shaft 20 arranged vertically at intervals. The first shaft 10 and the second shaft 20 may be in a vertical relationship in the same plane, but they may not touch each other, or It is the spatial vertical relationship of different planes. The driving gear 11 is coaxially installed on the first shaft 10, and the transmission gear 21 meshing with the driving gear 11 is coaxially installed on the second shaft 20. The transmission mechanism also includes The third shaft 30 arranged radially of 20, that is, the third shaft and the second shaft are located in the same plane and are perpendicular to each other. The third shaft 30 is controlled by the control assembly 4 to rotate around the second shaft 20. On the third shaft 30, the same The shaft is equipped with a driven gear 31 meshed with the transmission gear 21. The first shaft 10 is connected to...

Embodiment 2

[0036] A tilt-rotor unmanned aerial vehicle, comprising a motor 5 and a rotor 6 connected through the transmission mechanism, the first shaft 10 of the transmission mechanism is coaxially connected with the motor 5, and the third shaft 30 of the transmission mechanism is the same as the hub of the rotor 6 Shaft connection, when the rotor 6 of the tilt-rotor UAV rotates horizontally, the vertical take-off and landing of the tilt-rotor UAV can be realized, and when the rotor 6 rotates vertically, the high-speed and efficient cruise of the tilt-rotor UAV can be realized. 6 is connected with the motor 5 through a tiltable transmission mechanism, and the third shaft 30 of the tiltable transmission mechanism rotates around the second shaft 20 to realize the back and forth adjustment of the rotor 6 between horizontal plane rotation and vertical plane rotation, and During the tilting process of the rotor 6, it is always rotating, which realizes the tilting of the rotor 6 without the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com