Intelligent filled gas cylinder detection system and method

A technology of gas cylinders and gas cylinders, applied in the field of intelligent monitoring management and intelligent monitoring and management of gas cylinder filling, can solve problems such as failure to fill unqualified gas cylinders, threats to public personal and property safety, gas cylinder leakage and deflagration, etc., to achieve Solve the effect of monitoring illegal filling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to explain in detail the technical content, structural features, achieved goals and effects of the technical solution, the following will be described in detail in conjunction with specific embodiments and accompanying drawings.

[0022] The inventor collects the on-site video image data of the gas cylinder filling platform through the system;

[0023] The system extracts video clips or images from the collected on-site video images of the gas cylinder filling platform; video and image acquisition can be completed through cameras, monitoring probes and other equipment.

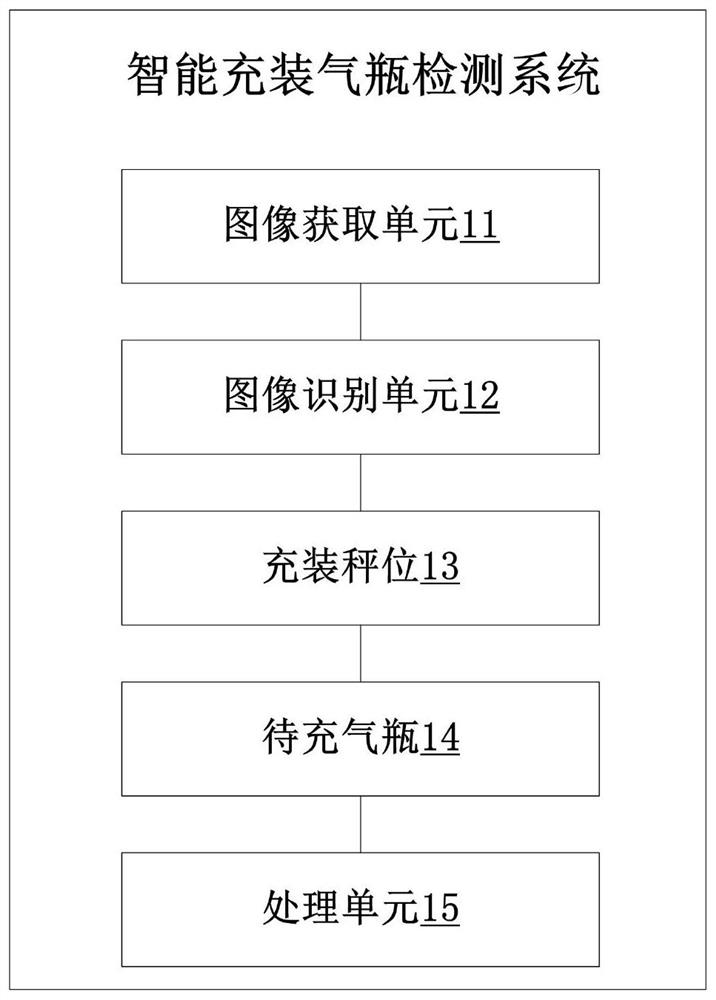

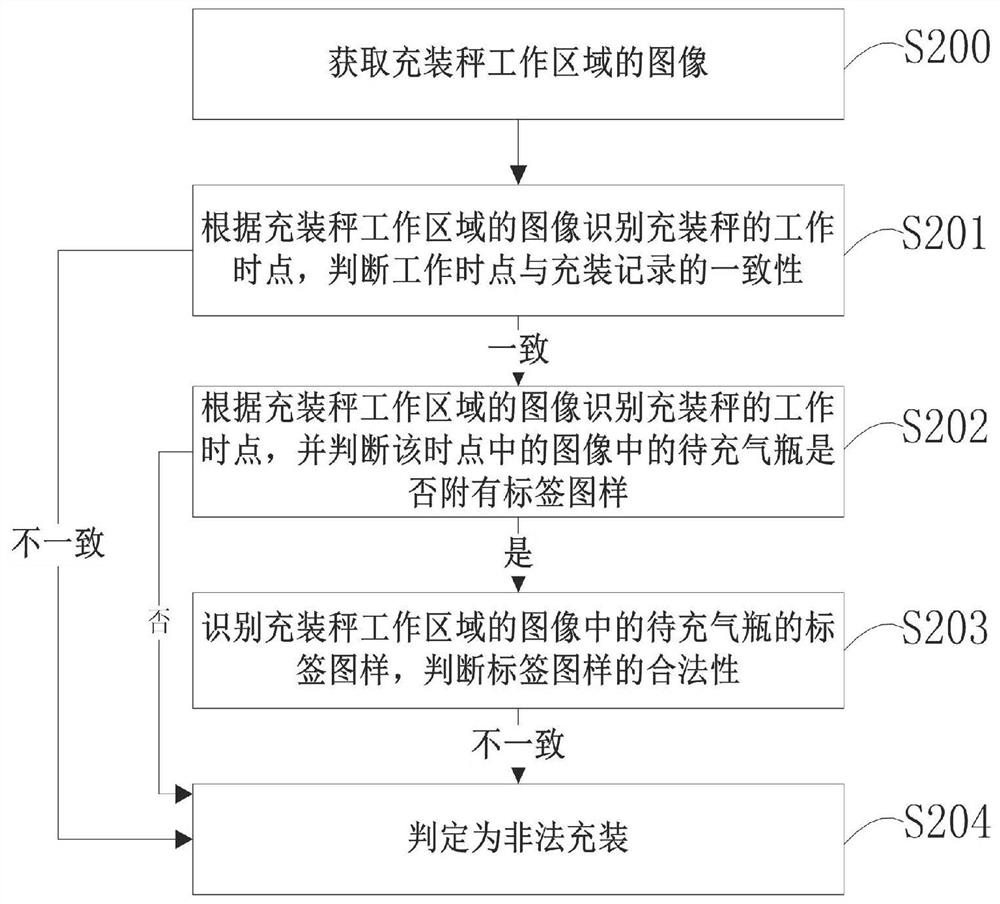

[0024] The AI recognition system (such as through the image recognition unit) will perform AI recognition and analysis on the scale position in the extracted video clip or image according to the coordinate data of each scale position marked on the image in advance, and obtain the scale position at the specified coordinate position. The result data of the time point when the cylinder to be inf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com