Stamping die and light guide plate thereof

A technology for pressing templates and molds, applied in the directions of light guide, printing, optics, etc., can solve the problems of the deterioration of the optical rotation performance of the light guide plate, the inconvenient structure of printing and pressing molds, and the inability to completely press the optical microstructure pattern, so as to improve the product life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

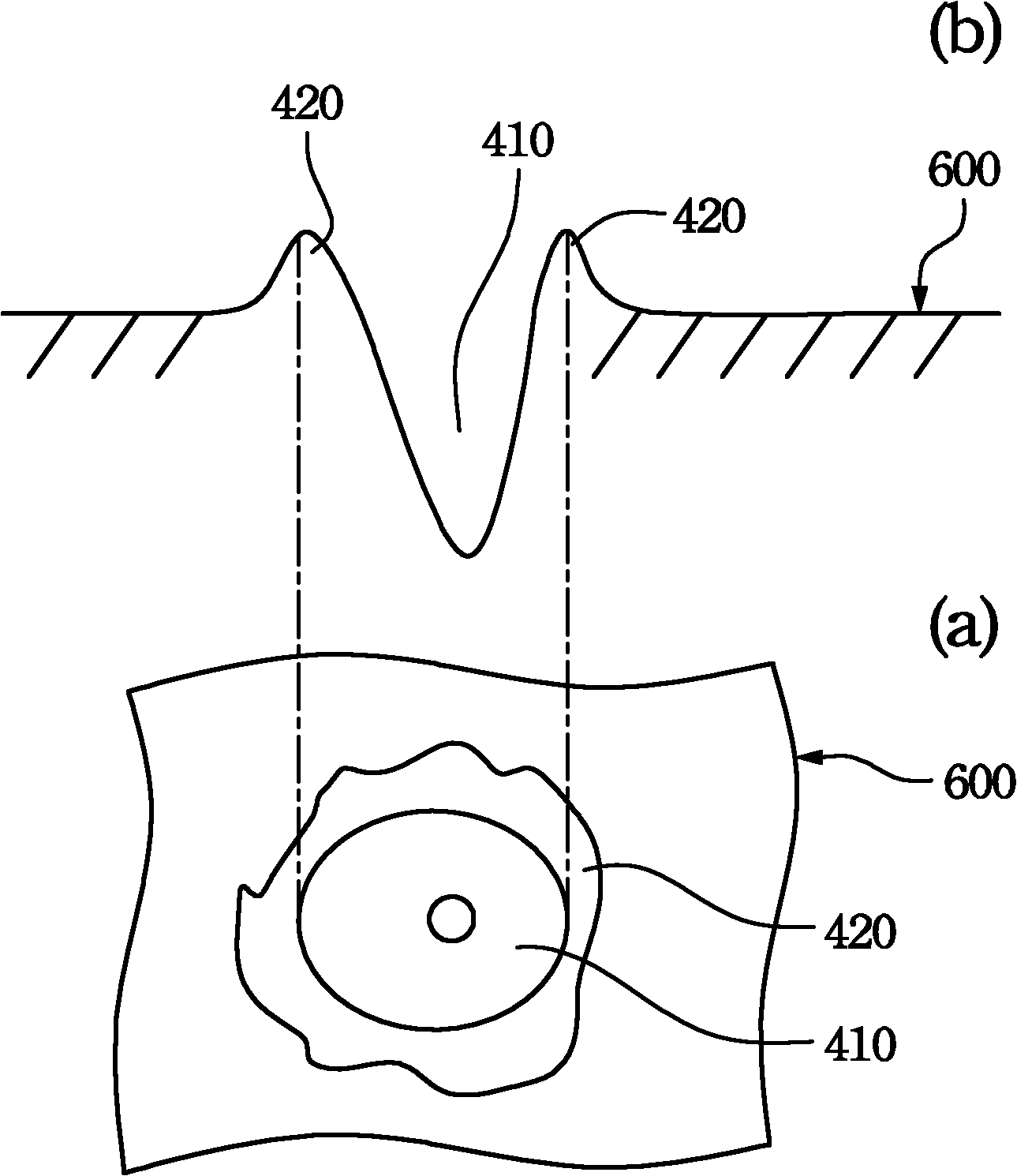

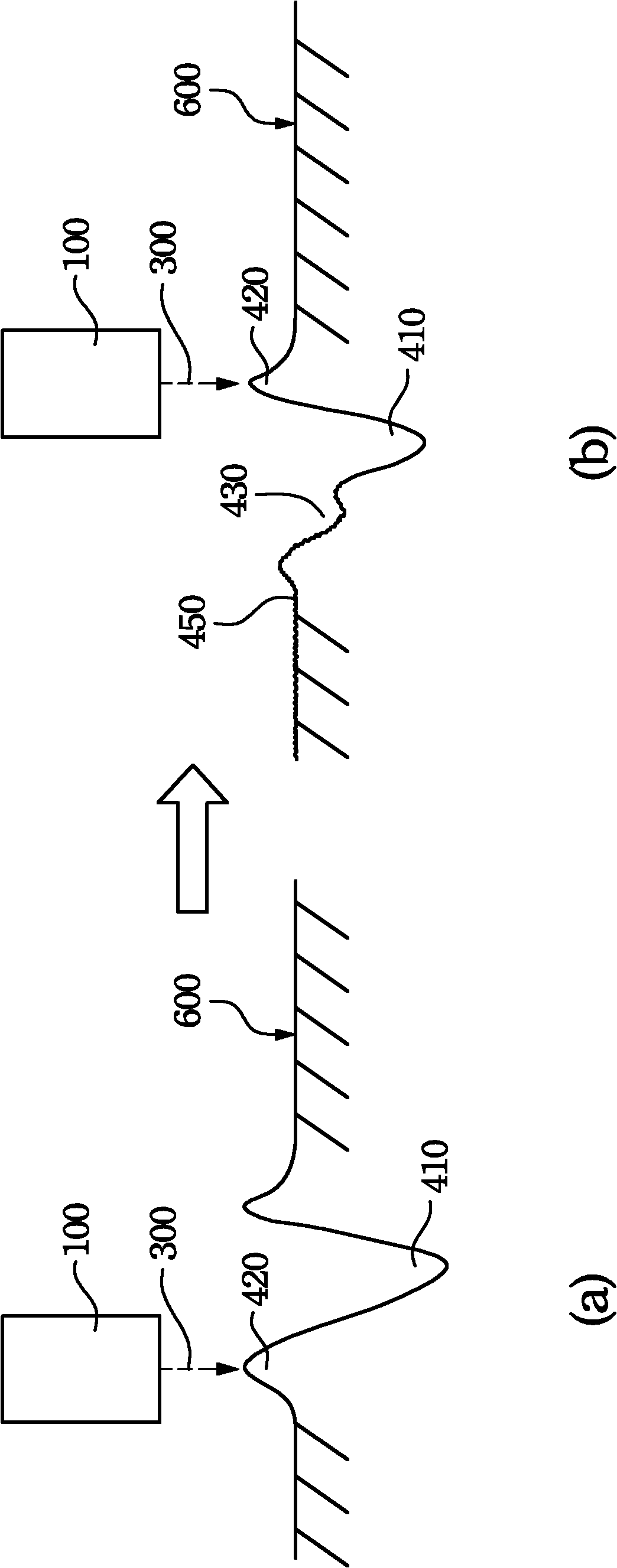

[0028] The invention discloses an embossing mold for completely embossing an optical microstructure pattern so as to maintain the optical rotation performance of a light guide plate.

[0029] The invention discloses an embossing mold, which is used to reduce the chance that the protrusions on the periphery of the micro-holes will fall off and fill up the micro-holes.

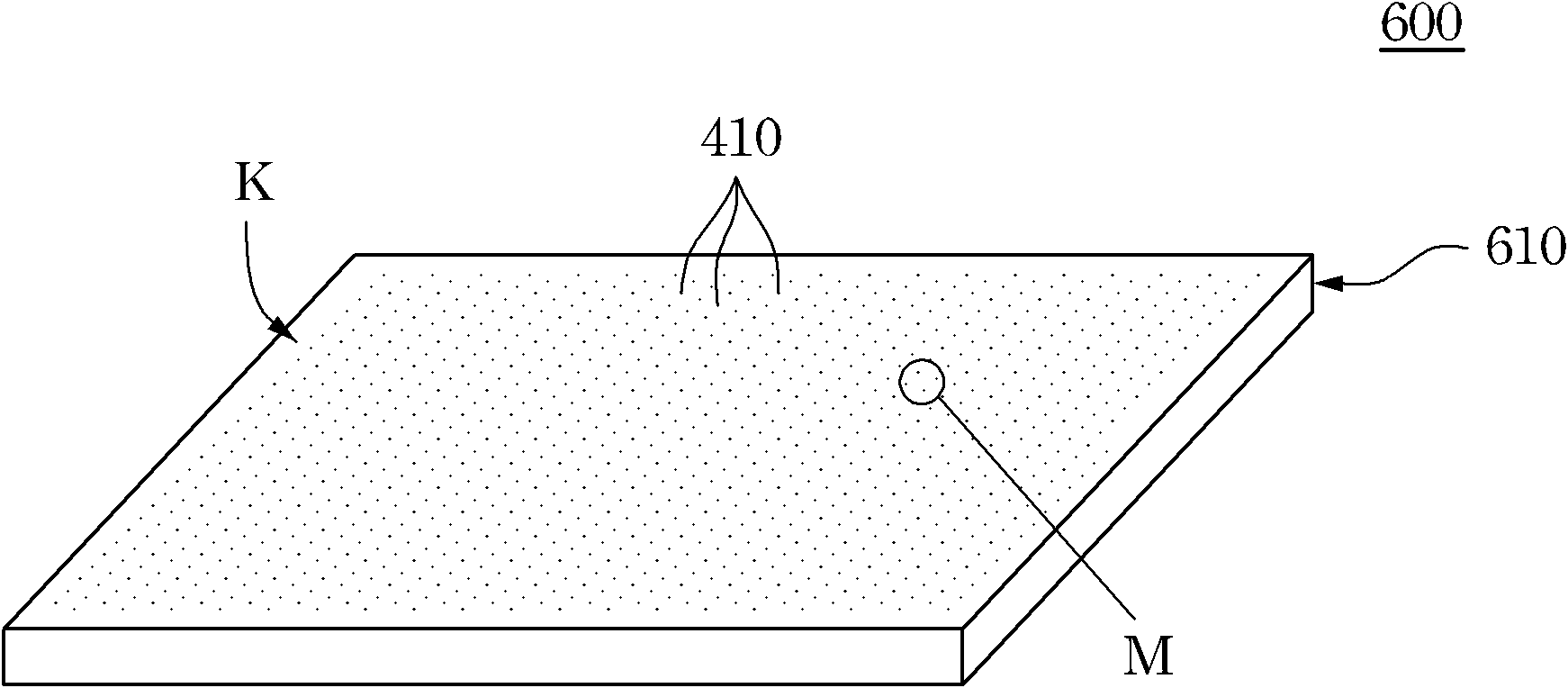

[0030] One embodiment of the present invention discloses an embossing mold. The embossing mold includes a body and a microhole aggregation pattern. The body has a stamping surface. The aggregate pattern of microholes is distributed on the printing surface and includes a plurality of microscopic concave holes. The periphery of each micro-recess has at least one protrusion, and the periphery of each micro-recess and the top surface of the protrusion both have melted surfaces, suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com