Girth welding method of duplex stainless steel bimetal composite pipe

A bimetallic composite pipe, duplex stainless steel technology, applied in welding equipment, metal processing equipment, welding/welding/cutting items, etc. The effect of high performance, high welding qualification rate and balanced welding seam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The girth welding welding method of duplex stainless steel bimetal composite pipe of the present invention comprises the following steps:

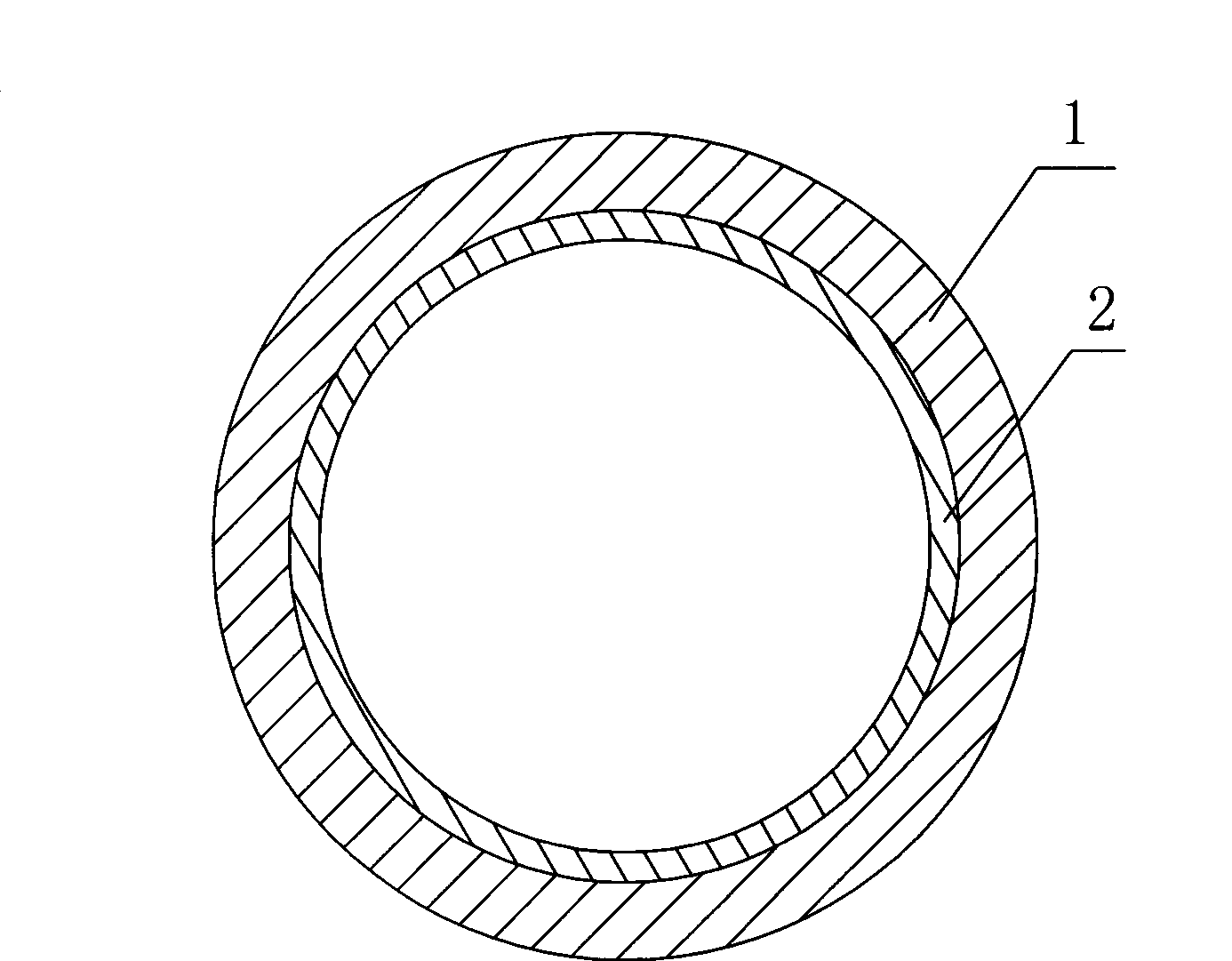

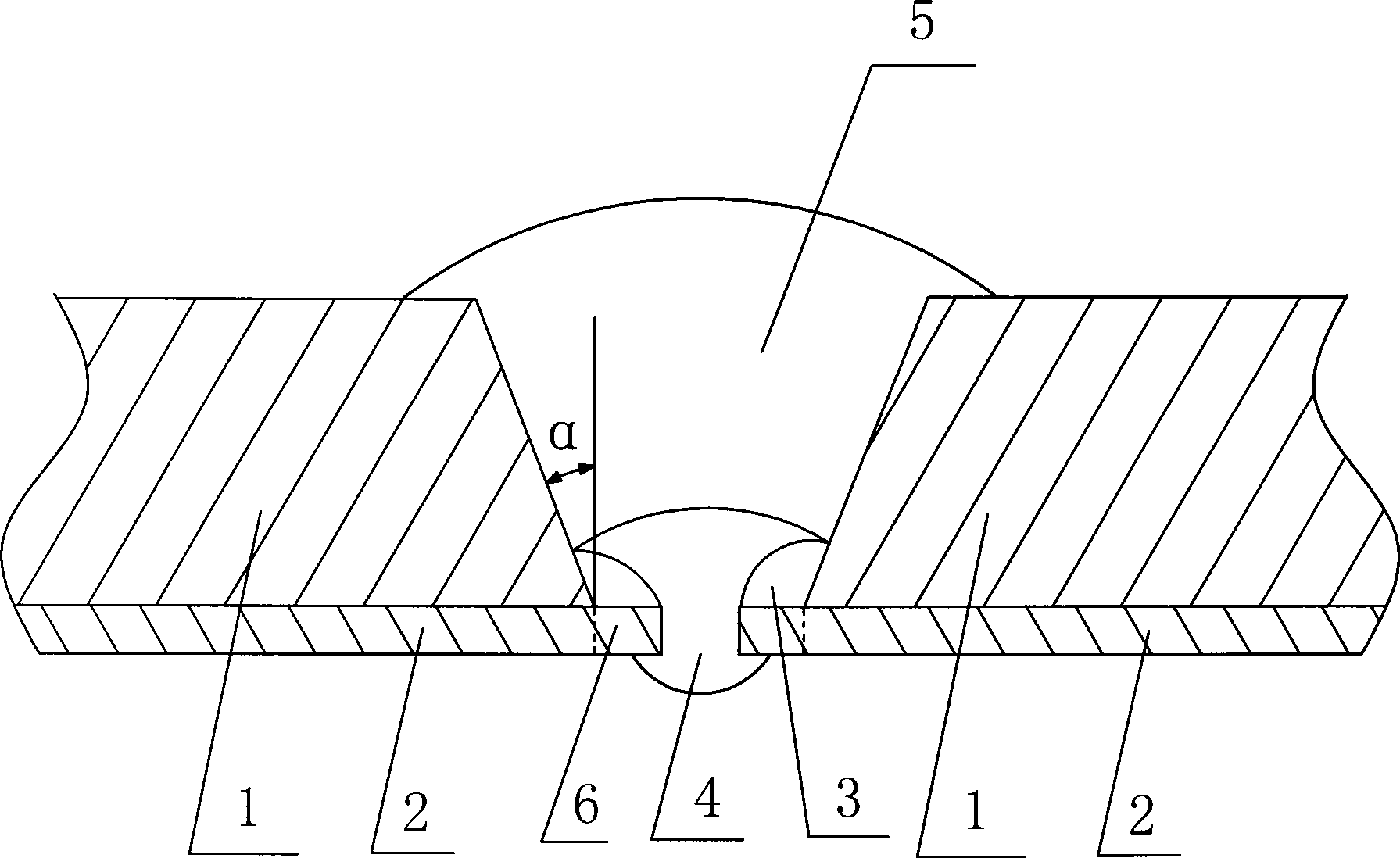

[0025] The first step, groove treatment: such as figure 1 As shown, the duplex stainless steel bimetallic composite pipe is composed of a duplex stainless steel lining pipe 2 with a wall thickness of 0.6-2 mm and a carbon steel base pipe 1 set outside the inner lining pipe 2; first, the base pipe 1 is welded The surface is machined with a V-shaped groove, the angle α of the groove is 45-55°, and the length of the liner 2 protruding from the base pipe 1, that is, the blunt edge 6, is 2-3 mm. In this embodiment, the base pipe 1 is 20 steel and its wall thickness is 7 mm. In practice, the base pipe 1 can also be 20G steel, L245NB pipeline steel or L360 pipeline steel, etc.; the material of the lining pipe 2 is 2205 duplex stainless steel And its wall thickness is 2mm. Firstly, the welding surface of the base pipe 1 is processed into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com