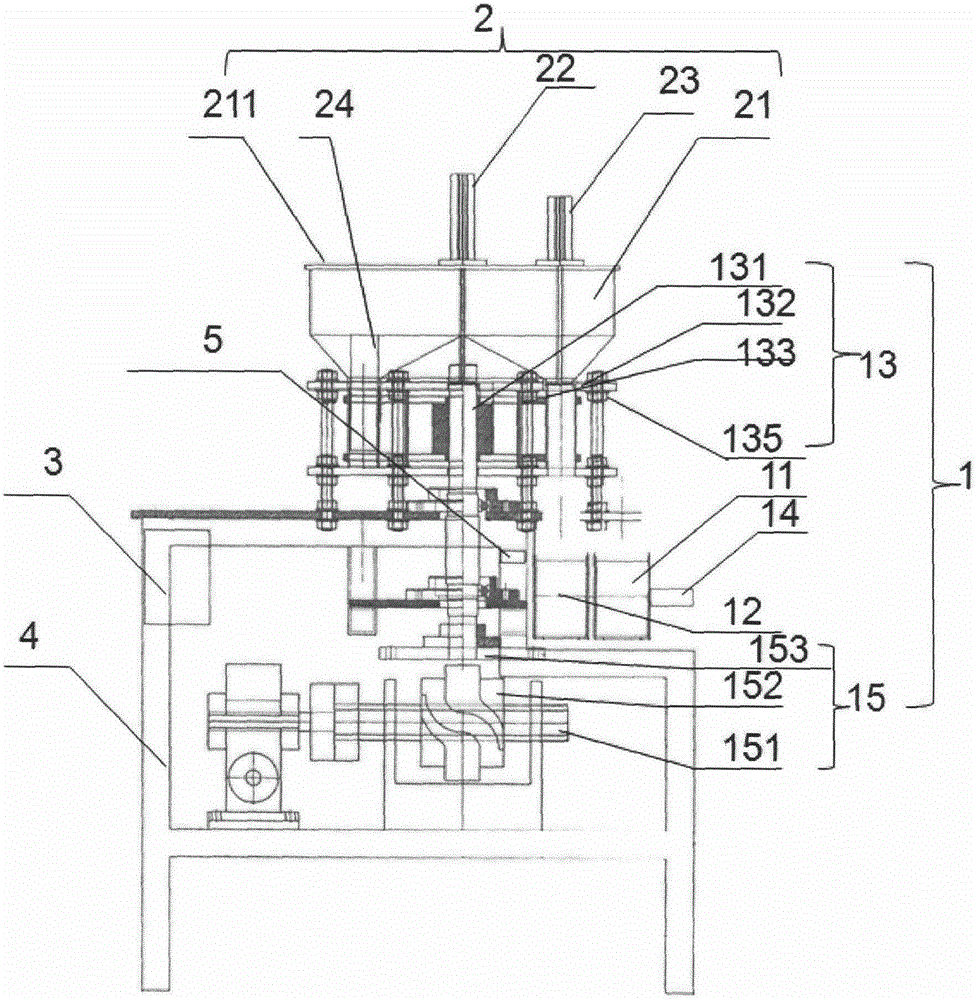

Full-automatic pickled vegetable filling machine

A fully automatic filling machine technology, applied in the field of packaging and pickle production, to avoid the output of empty pickle bottles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

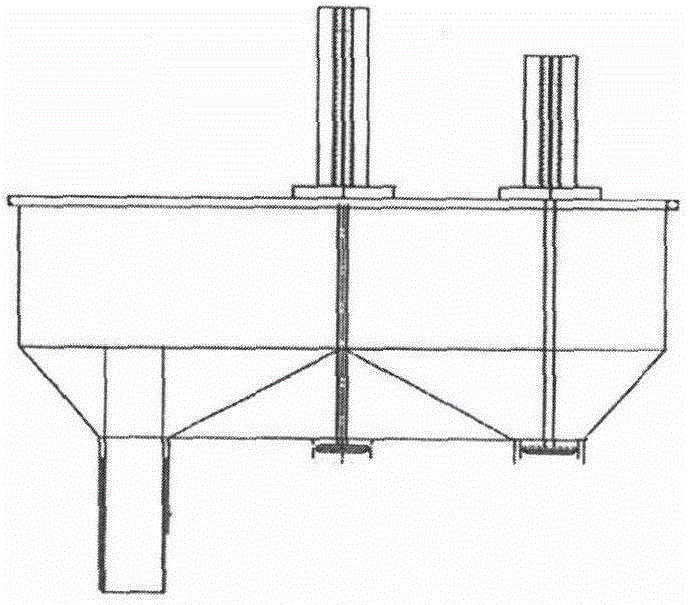

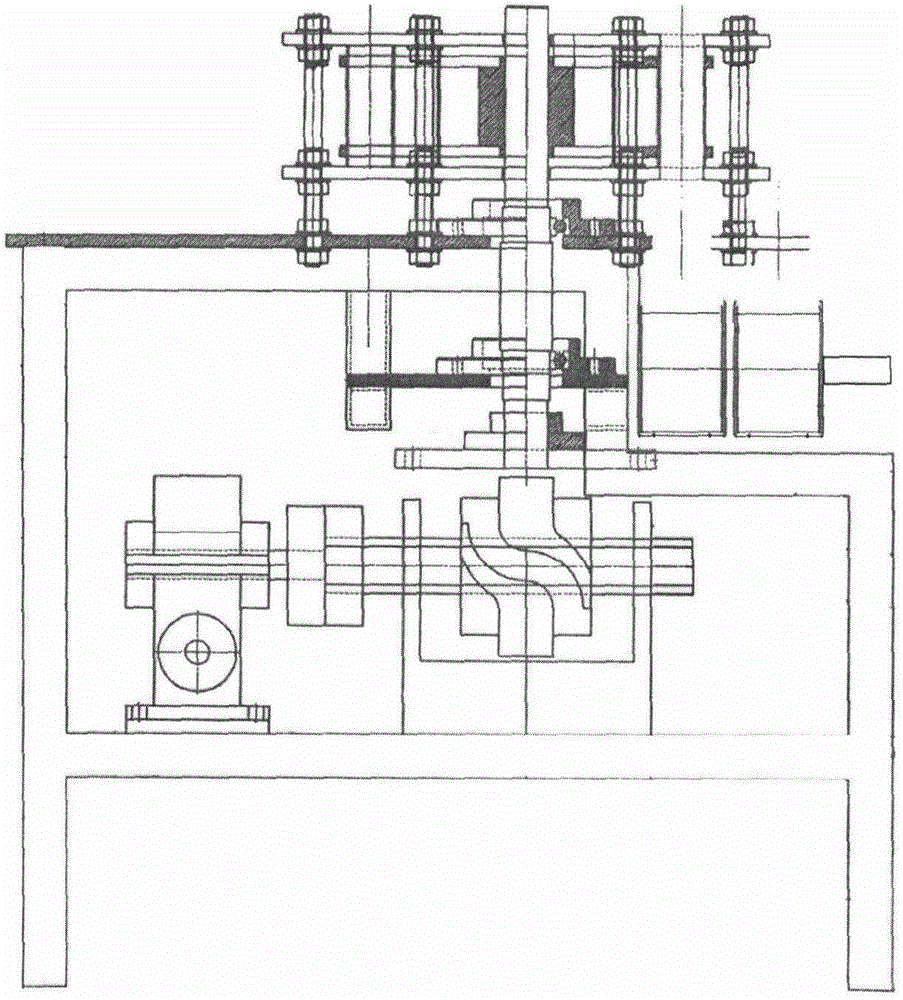

[0020] The working process of the present invention is as follows: after the pickle raw material is put into the hopper 21, start the mixer 22 to start working, start the first motor, and after the bottle feeding mechanism 11 starts to transport empty pickle bottles to the end of the bottle feeding mechanism 11, push the bottle mechanism 14 Push the pickle bottle onto the bottle outlet mechanism 12, the cam indexing mechanism 15 divides the bottles, and then the filling mechanism 2 fills the pickles. During the filling process, one of the cylinders 23 transfers the stirred pickles into the village material cup , then the filling transmission mechanism 13 rotates, and another cylinder compresses, and then fills for the second time after compression, and then compresses for the second time; after the compression is completed, the material is discharged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com