Device and method for metal filling

A technology for metal and storage tanks, which is applied in the field of metal filling devices and filling, which can solve the problems of affecting the accuracy of filling, the purity of filling metal, the inability to realize metal filling, and the loss of filling metal, so as to achieve a good filling effect , cost avoidance, high filling accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

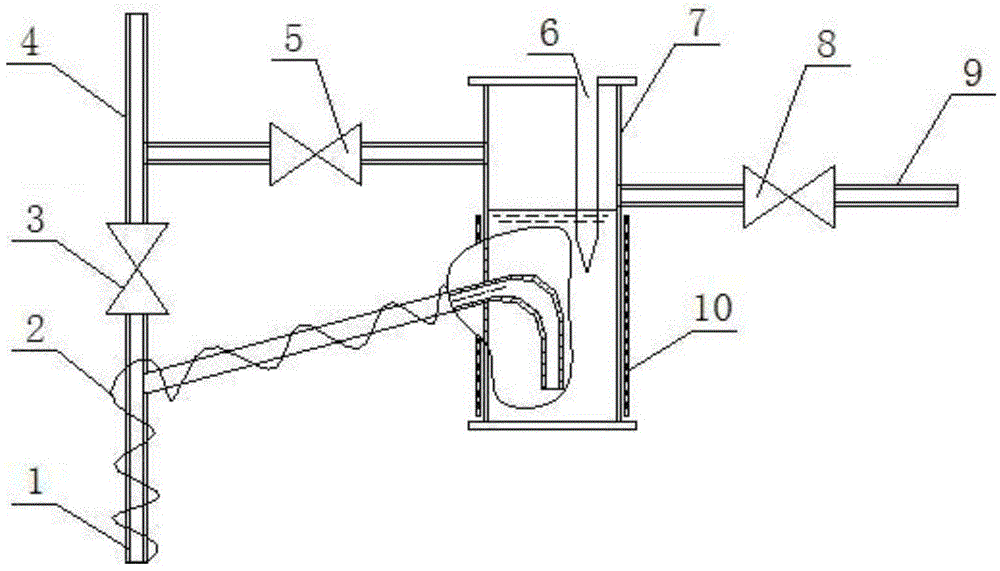

[0023] Adopt the metal filling device of the present invention to fill 20 grams of metal potassium in the single-port capillary, main steps are as follows:

[0024] (1) Get 28 grams of molten potassium according to calculations, inject a part of potassium into the storage tank until the potassium liquid level is slightly higher than the nozzle of the filling pipeline inside the storage tank; after the injected potassium is cooled and solidified, inject the remaining Potassium and wait for it to cool and solidify;

[0025] (2) Connect the single-port thin tube to be filled into the filling pipeline through the quick connector, make the vacuum valve and the exhaust valve in the open state, and the intake valve in the closed state, and evacuate through the vacuum pipeline;

[0026] (3) Close the vacuum valve and the exhaust valve, heat the temperature of the storage tank and the filling pipeline to 80°C through the heating module and the heating wire, so that the potassium in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com