Graphene modified PA6 production device and production process

A graphene modification and production device technology, applied in the field of nylon, can solve the problems of decreased toughness, affected dimensional stability, strong water absorption, etc., and achieves the effects of decreased relative viscosity, good product quality, and wide application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

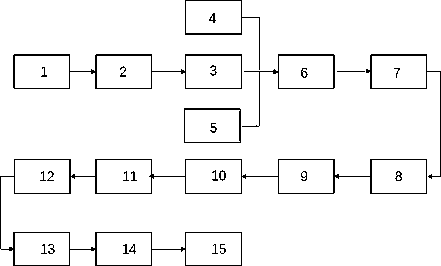

[0018] Such as figure 1 As shown, the present invention provides a kind of graphene modified PA6 production device, comprises: feeding machine 1, pulverizer 2, first storage tank 3, second storage tank 4, the 3rd storage tank 5, conveyor 6, mixing Bin 7, twin-screw extruder 8, belt casting machine 9, cooling air dryer 10, pelletizer 11, first dryer 12, transition tank 13, second dryer 14, packaging machine 15, the feeder 1 is connected to the inlet of the pulverizer 2, the outlet of the pulverizer 2 is connected to the inlet of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com