Catalyst for preparing isobutene by dehydrating tertiary butanol and preparation method of catalyst

A catalyst and isobutylene technology, applied in the direction of chemical instruments and methods, physical/chemical process catalysts, organic compounds/hydrides/coordination complex catalysts, etc., can solve the problems of multi-polymerization and temperature-resistant isobutylene, and reduce the use of Grade, overcoming temperature resistance, and reducing the effect of condensing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

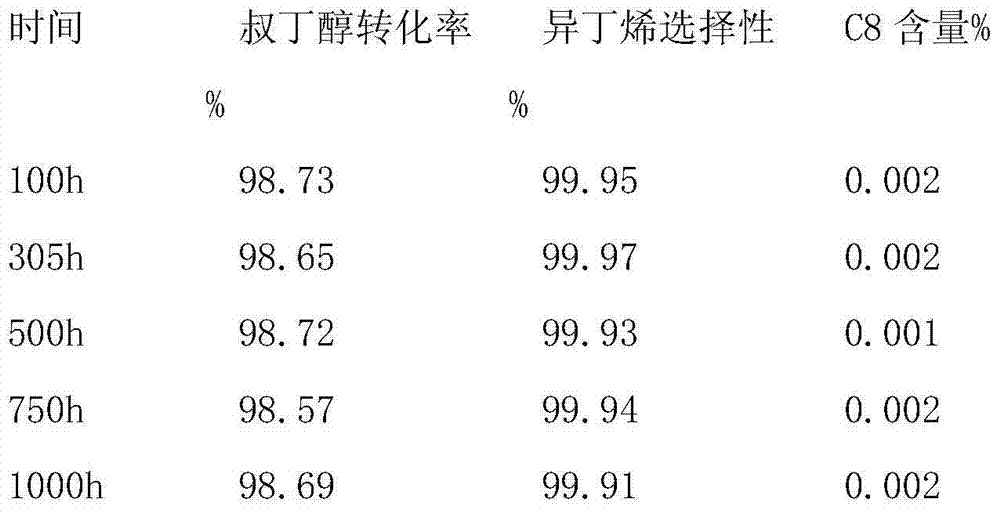

Embodiment 1

[0028] 1070.26g ZrOCl 2 , 210.57gTiCl 2 , 69.24gAlCl 3 After preparing a solution of 0.2mol / L, mix it evenly, under continuous stirring, add 0.5g of polymerization inhibitor THQ and 1.5g of dimethyl dodecyl silicon chloride, stir for 15min after adding, and mix the mixture with 50wt% ammonia water was dripped into the reactor simultaneously for precipitation, and the pH was controlled to be 9.5. After the precipitation was complete, it was aged for 5 hours, and washed with deionized water until there was no Cl - ions, the resulting precipitate was dried at 360K for 12h, and calcined at 853K for 4h to obtain a catalyst precursor, in which the catalyst substrate was 905.98g, and its composition was 15.6wt%TiO 2 , 2.9wt%Al 2 o 3 , 81.4wt%ZrO 2 , the inhibition part is 0.16wt% of the catalyst substrate.

[0029] The obtained catalyst precursor was dispersed in 10 L of 20 wt% (NH 4 )HS 2 o 8 Soak in the solution for 3.5h, filter the solution, rinse the solid with deionized...

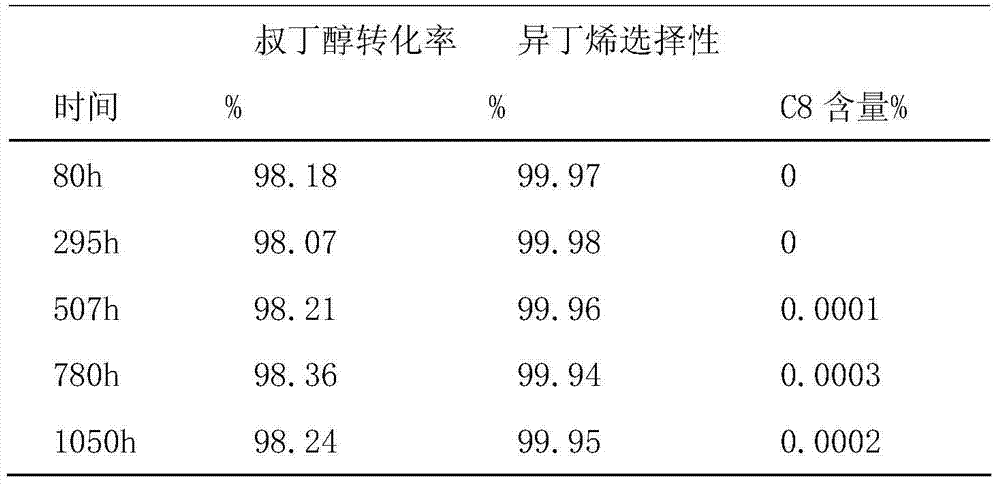

Embodiment 2

[0033] 1140.41gZrOCl 2 , 210.57gTiCl 2 , 34.62gAlCl 3 After preparing a 0.2mol / L solution, mix it evenly, under continuous heating and stirring, add 1g of polymerization inhibitor MTBHQ and 4g of methyl ethyl undecyl silicon chloride, stir for 15min after the addition, and mix the mixture Drop into the reactor simultaneously with 50% ammonia water for precipitation, control the pH to 9.85, age for 5 hours after the precipitation is complete, and wash with deionized water until there is no Cl - ions, the resulting precipitate was dried at 360K for 12h and calcined at 815K for 5h to obtain a catalyst precursor, wherein the catalyst substrate was 941.1g, and its composition was 15.1wt%TiO 2 , 1.4wt%Al 2 o 3 , 83.5wt%ZrO 2 , the polymerization inhibition part is 0.25wt% of the catalyst substrate.

[0034] The obtained catalyst matrix was dispersed in 10 L of 25wt% (NH 4 )HSO 3 Soak in the solution for 3h, filter the solution, rinse the solid with deionized water until the ...

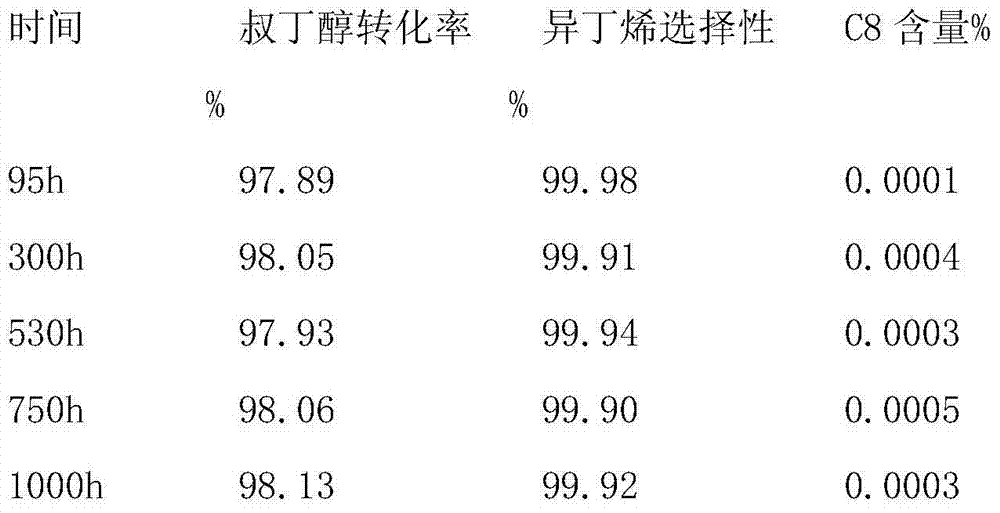

Embodiment 3

[0038] 1070.26g ZrOCl 2 , 280.76gTiCl 2 , 34.62gAlCl 3 After preparing a solution of 0.2mol / L, mix it evenly, under continuous heating and stirring, add 2g of polymerization inhibitor DNBP and 7g of dimethyl dodecyl silicon chloride, stir for 15min after adding, mix the mixture with 50% ammonia water was dripped into the reactor at the same time to precipitate, and the pH was controlled to be 9.5. After the precipitation was complete, it was aged for 5 hours, and washed with deionized water until there was no Cl - ions, the resulting precipitate was dried at 360K for 12h, and calcined at 837K for 4h to obtain a catalyst precursor, wherein the catalyst substrate was 940g, and its composition was 20.1%TiO 2 , 1.4%Al2O 3 , 78.5%ZrO 2 , the polymerization inhibition part is 0.42% of the catalyst matrix.

[0039] The obtained catalyst matrix was dispersed in 9 L of 30wt% (NH 4 )HSO 4 Soak in the solution for 1.6h, filter the solution, rinse the solid with deionized water unt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com