Efficient ultramicro crushing material bagging device

A technology of ultra-fine pulverization and materials, which is applied in the directions of packaging, transportation and packaging, and the type of packaged items. It can solve the problems of low filling efficiency, flying dust, and economic losses of enterprises, and achieve the improvement of filling efficiency, optimization of the working environment, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

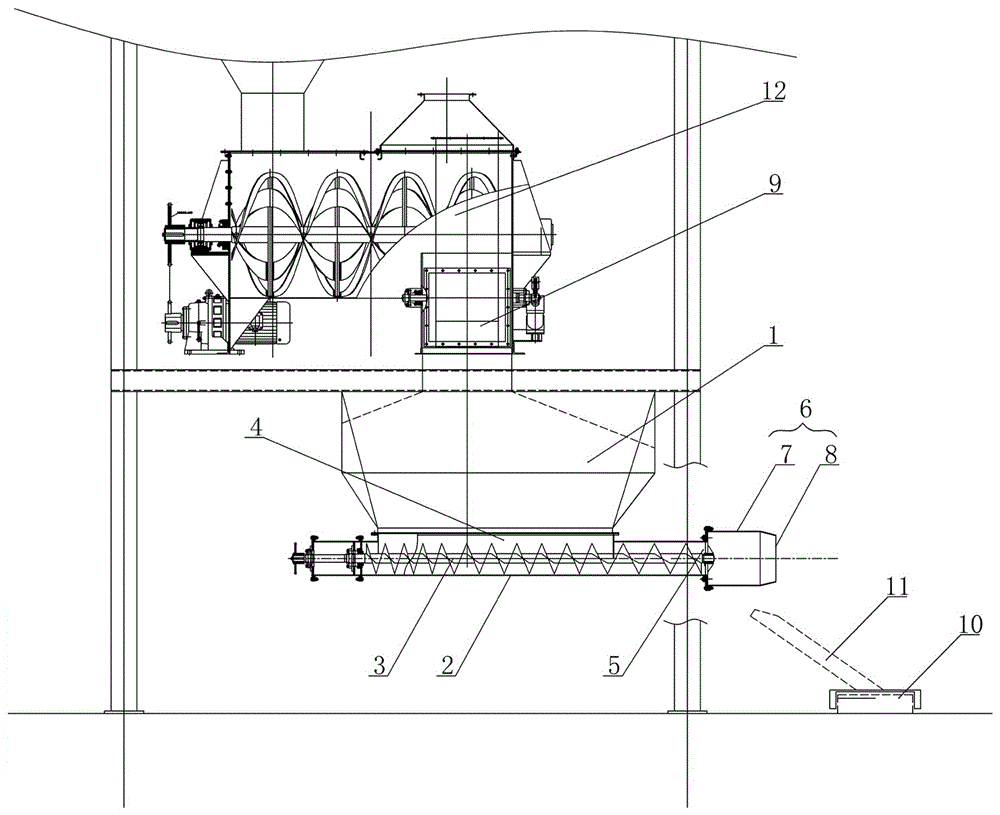

[0017] see figure 1 , a high-efficiency ultra-fine pulverized material filling device of the present invention includes a buffer bin 1 and a powder propulsion assembly, and an automatic gate 9 is arranged on the top of the buffer bin 1 for connecting with a pulverizing equipment 12 .

[0018] The powder propulsion assembly includes a cylinder body 2, an auger 3 and a power mechanism. The side of the cylinder body 2 is provided with a feed port 4 communicating with the buffer bin 1. The power mechanism is arranged at one end of the cylinder body 2. The other end of 2 is provided with a discharge port 5, and a degassing filling sleeve 6 is arranged coaxially on the cylinder body 2 at the discharge port 5, and the inner cavity diameter of the degassing filling sleeve 6 is smaller than that of the cylinder body. 2 has a large inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com