3D printing additive manufacturing method of Ti6Al4V injection molding feedstock

A 3D printing and additive manufacturing technology, applied in the manufacture of titanium alloy parts, Ti6Al4V injection molding feed 3D printing additive manufacturing field, can solve the problems affecting the use of parts, uneven filling, flow lines and other problems, to improve Application, strong comprehensive mechanical properties, good surface quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and examples, and the contents of the examples are not intended to limit the protection scope of the present invention.

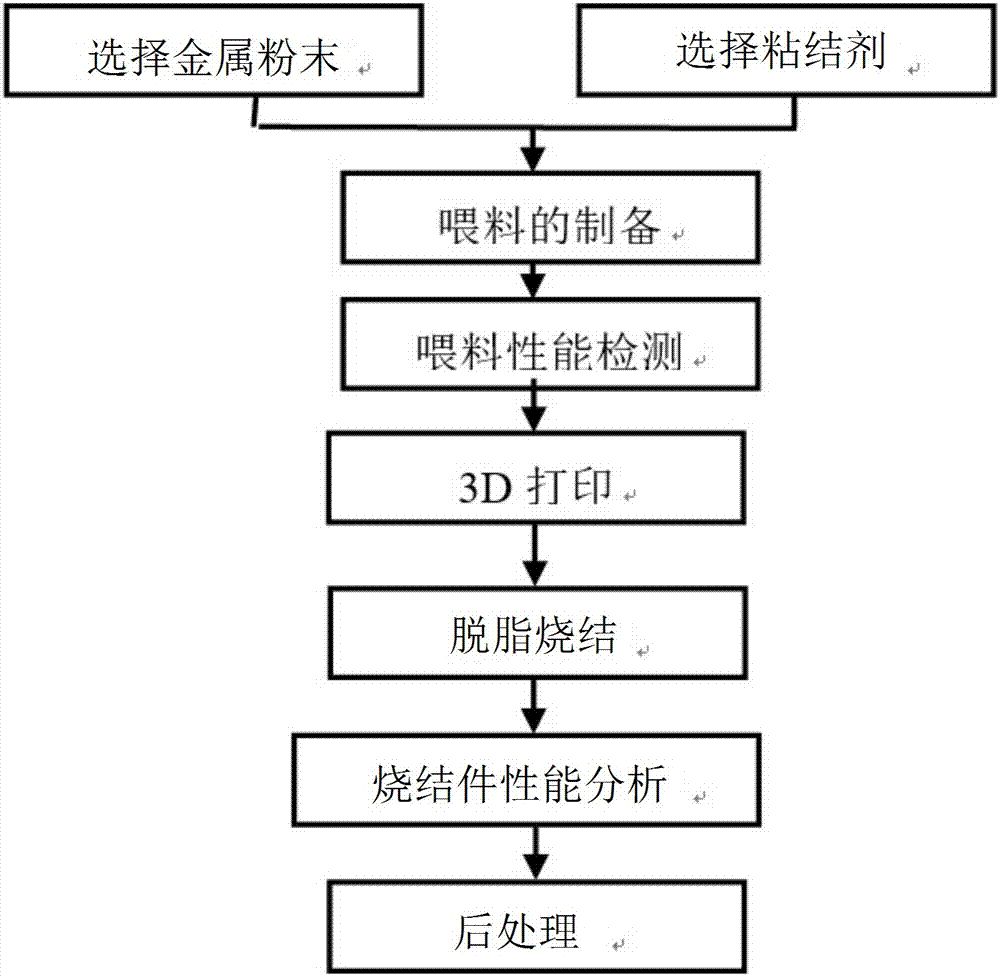

[0027] The invention relates to a Ti6Al4V injection molding feeding material 3D printing additive manufacturing method. In the present invention, the 3D printing additive manufacturing method comprises the following steps:

[0028] First, the metal powder and binder are selected.

[0029] To 3D print, suitable raw materials must be selected to prepare the feed. In the present invention, the selected metal powder is Ti6Al4V titanium alloy powder with a particle size of 16-26 microns. The selected adhesive is a plastic-based adhesive. Preferably, the plastic-based binder is a mixture of POM, PE, EVA, SA and PW. Among them, the mass percentage of each component is: POM 75%-89%; PE 4%-10%; PW 3%-10%P; SA 2%-8%; EVA 1%-10%. The choice of this metal pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com