Far infrared viscose filament and preparing method thereof

A viscose filament and a manufacturing method are used in textile raw materials and manufacturing, viscose filaments containing functional additives and manufacturing fields, which can solve problems such as discounts on health care functions, and achieve increased added value, considerable market prospects and good market prospects. Social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

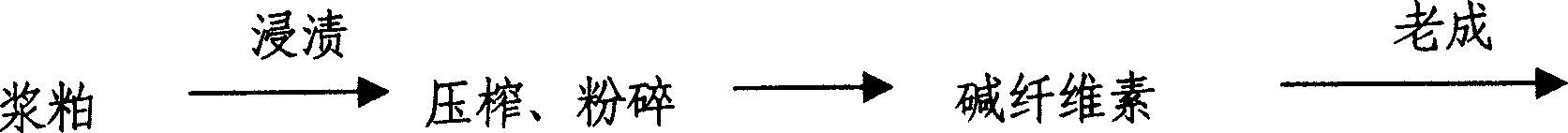

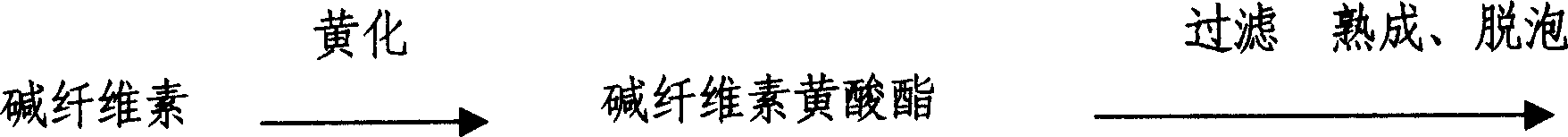

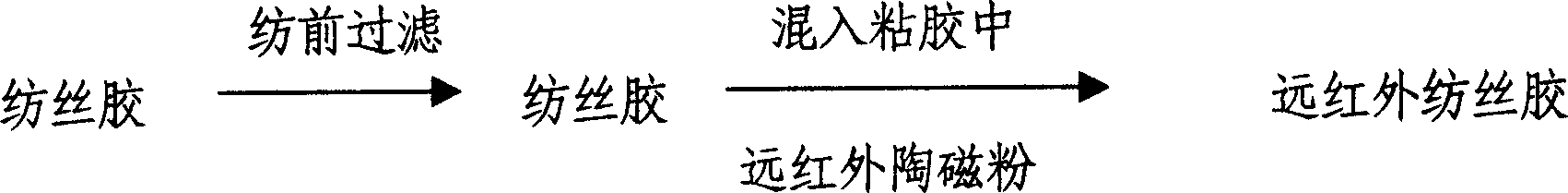

[0014] The manufacture of far-infrared viscose viscose filaments is divided into post-processing method and blended spinning method. The post-treatment method is to make the far-infrared ceramic powder, dispersant, and binder into a post-treatment bath in a certain proportion, add a process to the post-treatment of the formed silk cake, and evenly coat the far-infrared bath on the viscous On the glue filament, the far-infrared viscose filament finished product is obtained by drying. This method has low cost and simple process, but the wash fastness is poor, and the handle and color are affected. The method adopted in the present invention is the blended spinning method, which is to disperse the far-infrared ceramic powder evenly in the viscose solution, and then prepare the far-infrared ceramic powder with a conventional spinning method under appropriate process conditions and stable process control. Viscose filament. This method can be used to obtain permanent far-infrared ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com