WINCE system-based rail transit real-time detection system and detection method

A real-time detection and rail transit technology, applied in tracks, track maintenance, roads, etc., can solve the problems of lack of planning for inspectors, unable to form information data in real time, etc., to improve work efficiency and work quality, and strengthen safety assurance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

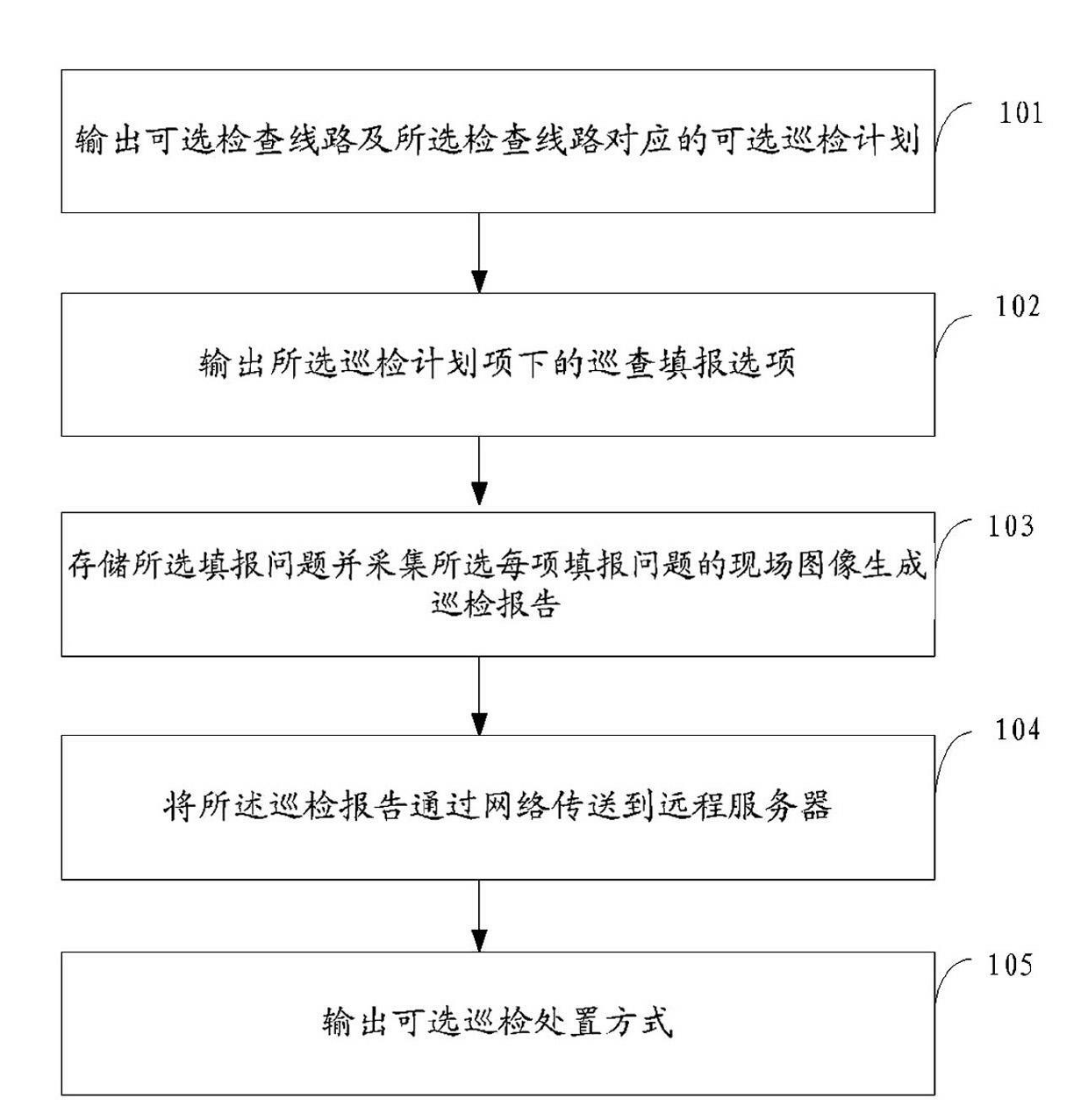

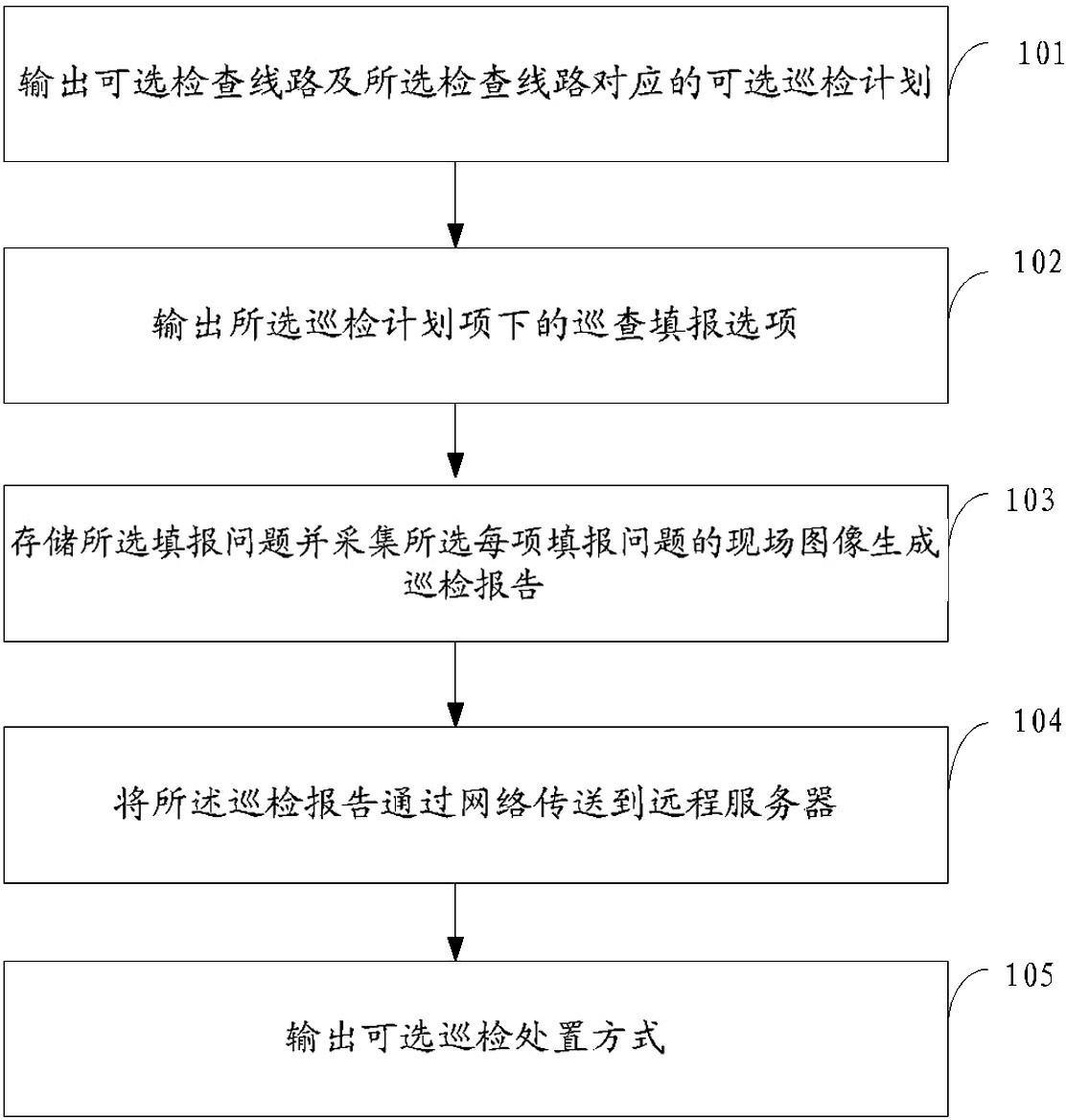

Examples

Embodiment 2

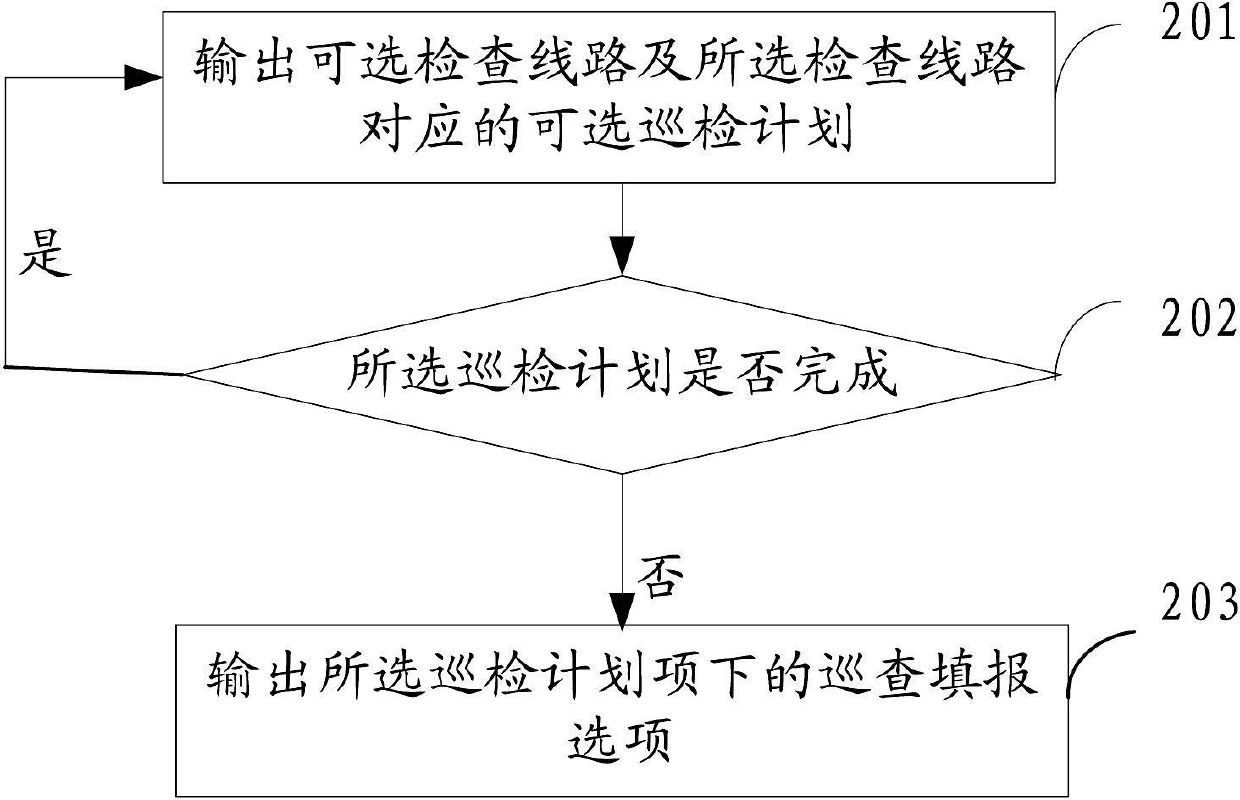

[0056] In order to further protect the personal safety of the user, the embodiment of the present invention may further include the following steps after the step of outputting the optional inspection line and the optional inspection plan corresponding to the selected inspection line in step 101:

[0057] Judge whether the user’s location on the map is within the preset safety range, if yes, output the patrol filling options corresponding to the selected patrol plan, if not, perform a safety information warning, and output the selected patrol after the safety is confirmed The inspection filling option corresponding to the inspection plan.

[0058] Preferably, the safety range is within a radius of 10 meters from the preset safety hazard point. In specific implementation, the positioning display can be positioned using GPS technology, and the location of the map can be displayed through GIS (Geographic Information System Technology).

[0059] Specifically, after the inspector enters t...

Embodiment 3

[0065] In order to facilitate users to query their own historical inspections and inspection data, after the step of outputting the inspection filling options under the selected inspection plan, the embodiment of the present invention further includes the following steps: outputting the historical inspections under the selected inspection plan Records and inspection data, including exploration data, design data, construction data, and third-party data, are for users to use during inspections.

Embodiment 4

[0067] See Figure 4 In the embodiment of the present invention, after transmitting the inspection report to the remote server via the network in step S104, it further includes the following step: calculating and outputting an early warning level showing the problem to be handled reflected in the inspection report.

[0068] According to the displayed warning level, the user can choose the corresponding disposal method when proceeding to the next operation.

[0069] The specific implementation process is described in detail as follows: Step 401: Transmit the inspection report to a remote server through the network.

[0070] Step 402: Calculate and output the warning level of the problem to be handled as reflected in the inspection report.

[0071] Step 403: Output optional patrol inspection handling methods.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com