Construction process of precast concrete channel

A technology of prefabricated concrete and construction technology, which is applied in waterway systems, water conservancy projects, artificial waterways, etc. It can solve the problems of large investment in cast-in-place trench formwork, difficulty in ensuring the quality of concrete construction, and common defects on the concrete surface, etc., and achieves fast construction speed , low impact on the surrounding environment, good impermeability and seismic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

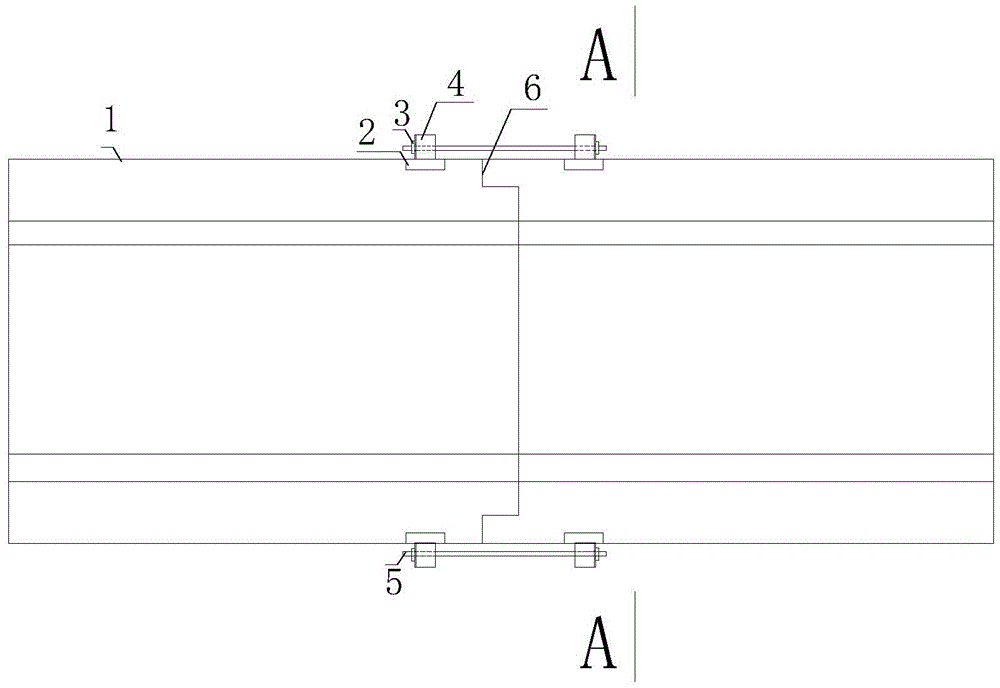

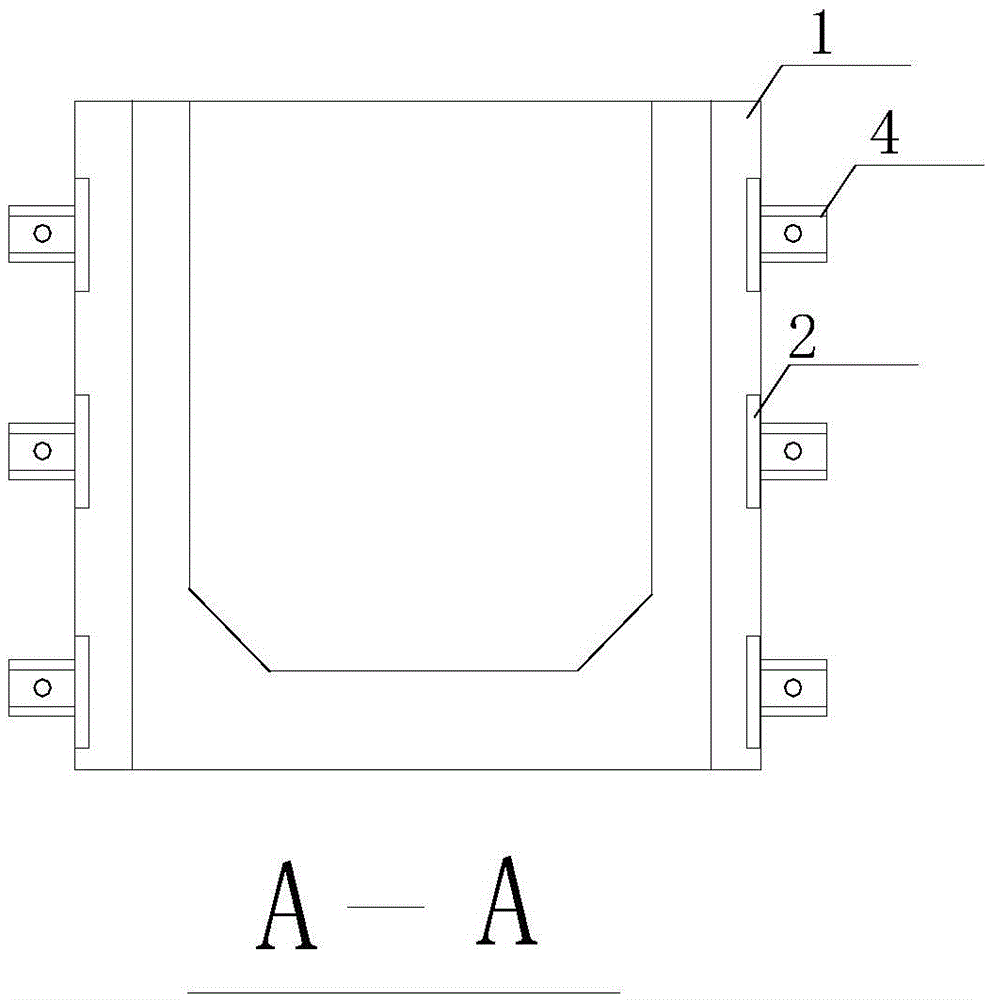

[0024] The following will describe in detail the embodiments of the present invention with reference to the accompanying drawings.

[0025] A construction process of precast concrete trench, including steps:

[0026] a. Sub-section:

[0027] According to the load capacity of the vertical transport machinery, the sections are reasonably divided according to the length of the channel 1, which is a reinforced concrete channel;

[0028] b. Channel 1 processing:

[0029] Prefabrication of each segmented channel 1 by segmented template processing; embedded parts on both sides of the channel 1 interface, and the interface is designed according to the bite;

[0030] c. Foundation treatment and cushion construction:

[0031] Excavate the soft soil of the trench 1 cushion, then replace it with sand or gravel to level it, and ram it layer by layer to the density required by the design, and pour the trench 1 cushion;

[0032] d. Measurement positioning:

[0033] Measure the centerline of channel 1 acco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com