Concrete roofing and ground anti-seepage leak-proof agent and anti-seepage leak-proof method

A technology of concrete roofing and leakage repairing agent, which is applied in building maintenance, construction, building construction, etc., can solve the problems of leakage, temporary cure and not the root cause, and achieve the effect of easy-to-obtain raw materials, low cost and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

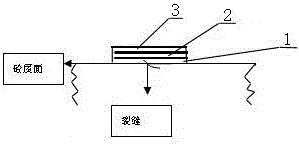

Image

Examples

Embodiment 1

[0029] An anti-seepage and leak-remediating agent for concrete roof and ground, which is composed of tung oil and cement, and the volume ratio of the tung oil and cement is 1:1.

[0030] The tung oil is raw squeezed tung oil.

[0031] The cement is Portland cement with a compressive strength of 42.5Mpa.

Embodiment 2

[0033] An anti-seepage and leak-remediating agent for concrete roof and ground, which is composed of tung oil and cement, and the volume ratio of the tung oil and cement is 1:3.

[0034] The tung oil is raw squeezed tung oil.

[0035] The cement is Portland cement with a compressive strength of 52.5Mpa.

Embodiment 3

[0037] An anti-seepage and leak-remediating agent for concrete roof and ground, which is composed of tung oil and cement, and the volume ratio of the tung oil and cement is 1:2.

[0038] The tung oil is raw squeezed tung oil.

[0039] The cement is Portland cement with a compressive strength of 42.5Mpa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com