A rh vacuum tank repairing device

A vacuum tank repairing technology, which is applied in the field of RH vacuum tank repairing devices, can solve the problems of lowering the repairing efficiency of different tanks, low safety, unsatisfactory, etc., and achieves reliable lifting, good safety, and low working surface Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings.

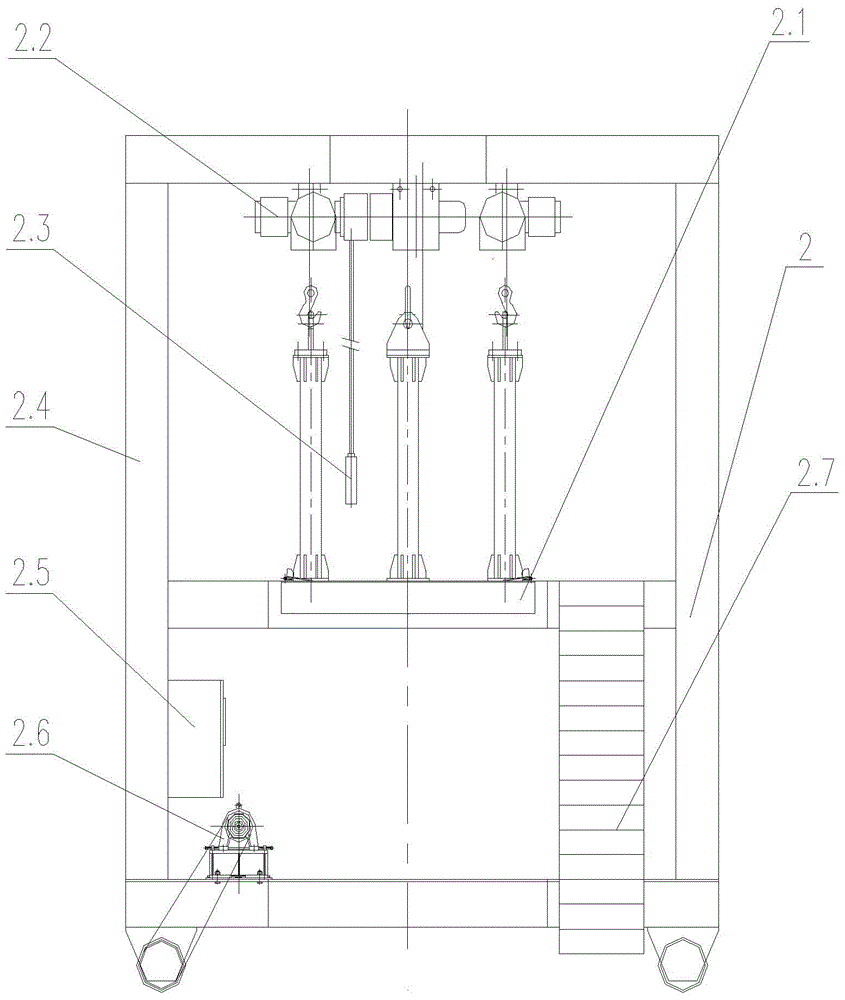

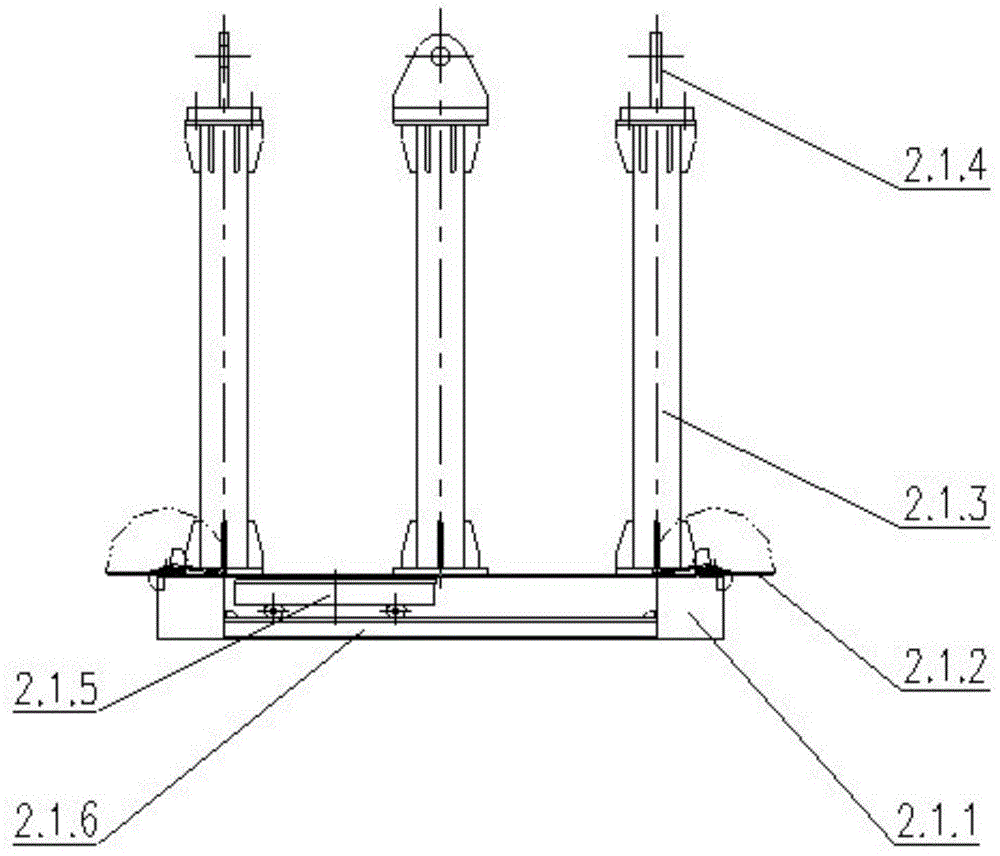

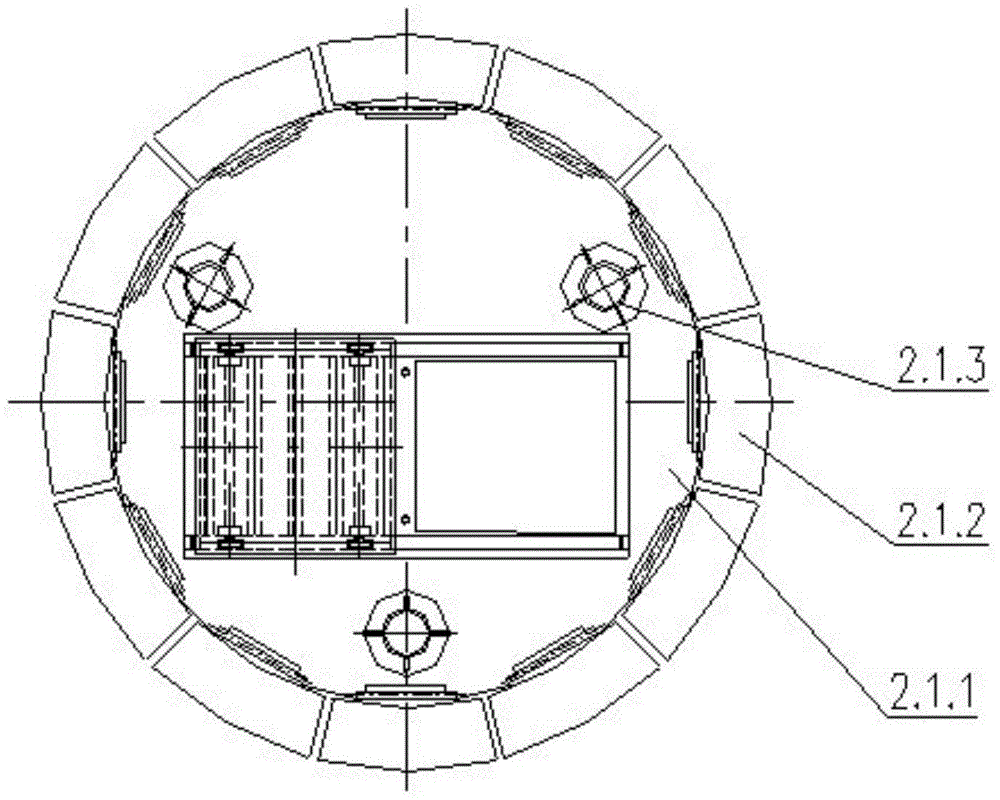

[0018] see figure 1 , a RH vacuum tank repairing device, including a repairing trolley 2, the repairing trolley 2 includes a vehicle frame 2.4, the vehicle frame 2.4 is a three-layer steel structure frame, the top layer is fixed with a lifting mechanism 2.2, and the lifting platform 2.1 is suspended On the lifting mechanism 2.2, the lifting platform 2.1 can move vertically on the repairing trolley 2. The lifting mechanism 2.2 is electrically connected to and controlled by the lifting controller 2.3. The bottom layer of the vehicle frame 2.4 is equipped with a mobile controller 2.5 and a driving mechanism 2.6 , the driving mechanism 2.6 is electrically connected with the mobile controller 2.5 and is controlled by it to smoothly adjust the position of the repairing trolley 2, and a straight ladder 2.7 is provided between the middle layer and the bottom layer of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com