Cleaning barrel of cleaning device

A cleaning device and cleaning barrel technology, applied in the field of cleaning barrels, can solve the problems of high mop barrel height, inconvenient packaging and transportation, and large floor space, and achieve the requirements of reducing the height of the barrel body, facilitating product packaging and transportation, and reducing the lifting stroke Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

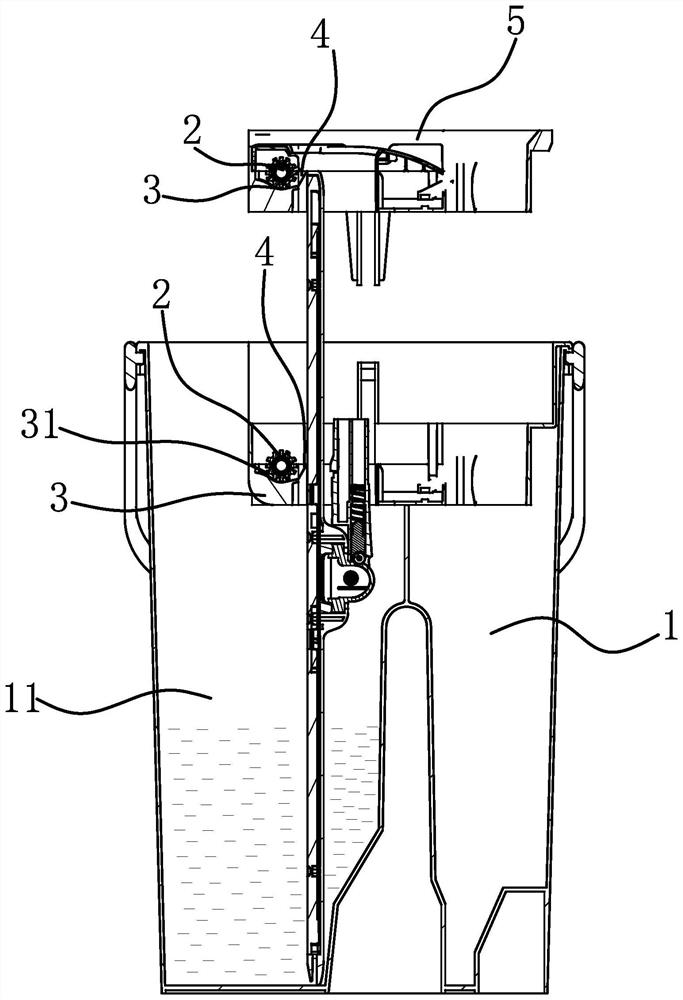

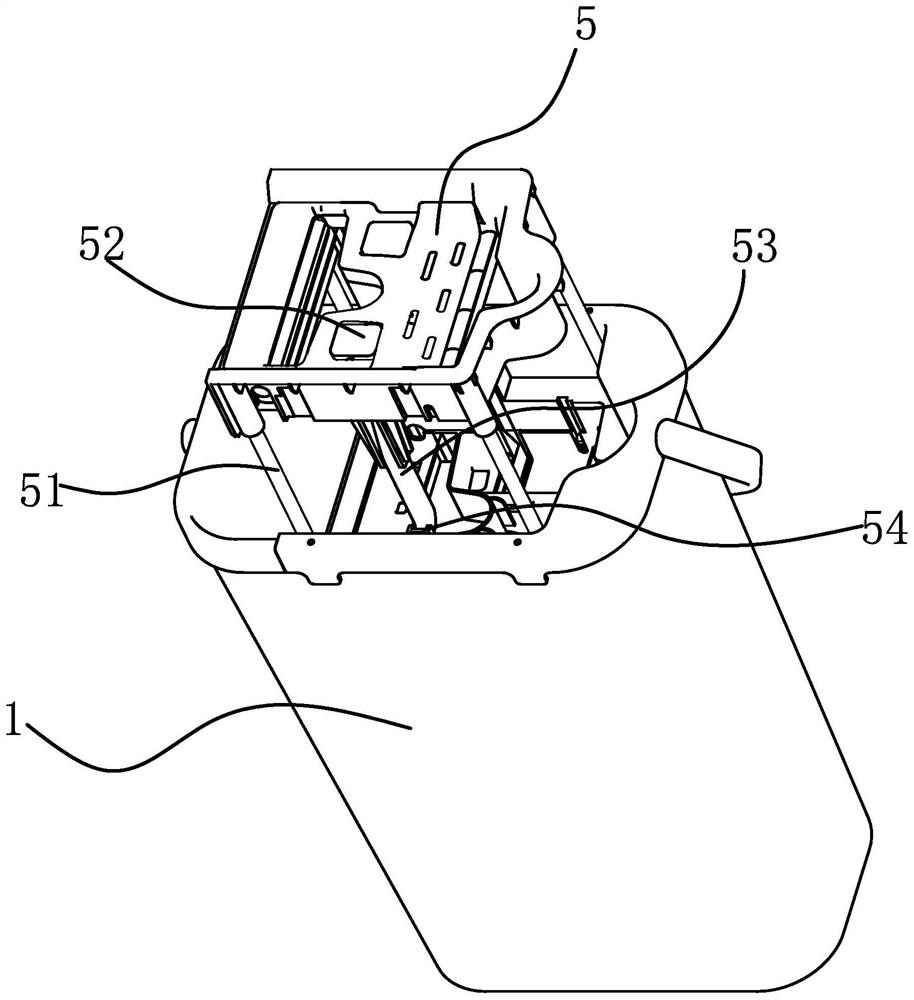

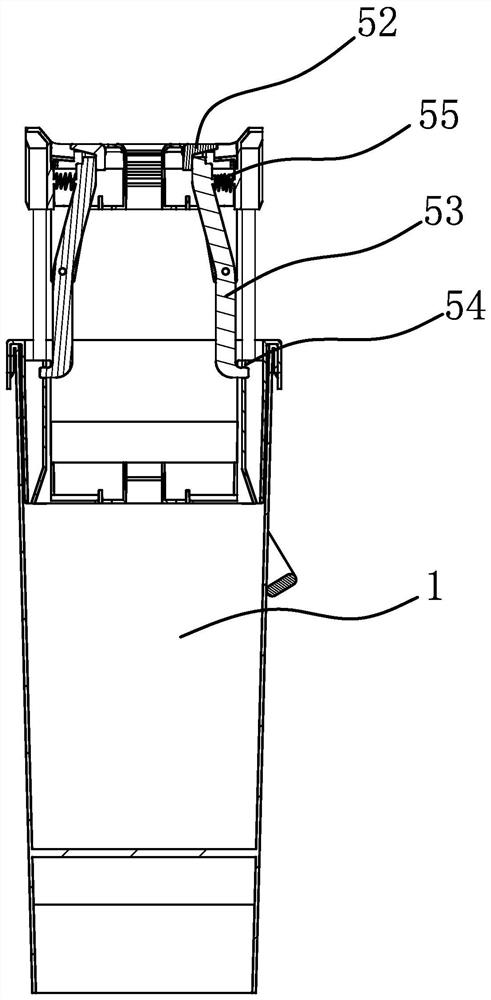

[0051] Such as Figure 1-3 As shown, the cleaning barrel of the cleaning device includes a barrel body 1, the barrel body 1 is provided with an opening, the cleaning device can enter the barrel body 1 along the opening of the barrel body 1, and the barrel body 1 is provided with a A water supply structure that wets at least a part of the cleaning device that extends into the barrel body 1. The water supply mechanism is an accommodating chamber 11 disposed in the barrel body 1, and the accommodating chamber 11 has a water storage function. The bucket body 1 is provided with a transfer mechanism that uses the movement of the cleaning device to lift the liquid in the wet part of the cleaning device and transfer it to the non-wet part of the cleaning device. The element 2 can transfer the liquid from the wetted part of the cleaning device to the water-carrying part 2 and release it to the non-wetted part of the cleaning device. The water-carrying part 2 is a roller or a sponge, e...

Embodiment 2

[0057] The principle of the transfer mechanism of this embodiment is the same as that of Embodiment 1, the difference lies in the water supply structure, such as Figure 4-5 As shown, in this embodiment, the water supply mechanism is a water outlet device arranged in the barrel body 1, and the water outlet device includes a water outlet 6, and the water outlet direction of the water outlet 6 faces the cleaning device. The water on the water outlet 6 flows to the cleaning device. The water can flow out from the water storage bucket 7, or it can be an external water source, or even manually poured water. In this embodiment, the water outlet device also includes a The water storage bucket 7 is connected with the water outlet 6, and the water outlet 6 is provided with a water outlet valve 71 for controlling the opening and closing of the water outlet 6. The barrel body 1 is provided with a link mechanism, and the link mechanism controls the on-off of the water outlet valve 71 . T...

Embodiment 3

[0061] Such as Figure 6-7 As shown, the working principle of this embodiment is basically the same as that of Embodiment 1, the difference is that the transfer mechanism includes a scraper 10, and the scraper 10 can scrape off and release the liquid in the wetted part of the cleaning device. Clean the unwetted part of the device.

[0062]The scraper 10 includes a wiper part 4 arranged in the barrel body 1 and a water guide part arranged under the scraper, the wiper part 4 can scrape off the liquid in the wet part of the cleaning device and pass it through the water guide Divert the flow to the unwetted part of the cleaning device.

[0063] The wiper part 4 is movably connected to the bucket body 1, and the wiper part 4 does not play the role of wiping when the cleaning device rises, and the scraper 10 plays the role of wiping when the cleaning device goes down.

[0064] When in use, the wetted part of the cleaning device is lifted up, and the scraper 10 rotates until the wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com