Elevator

An elevator and cable technology, applied in the elevator field, can solve the problems of increased cost, large partial load, and increased self-weight of the cable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

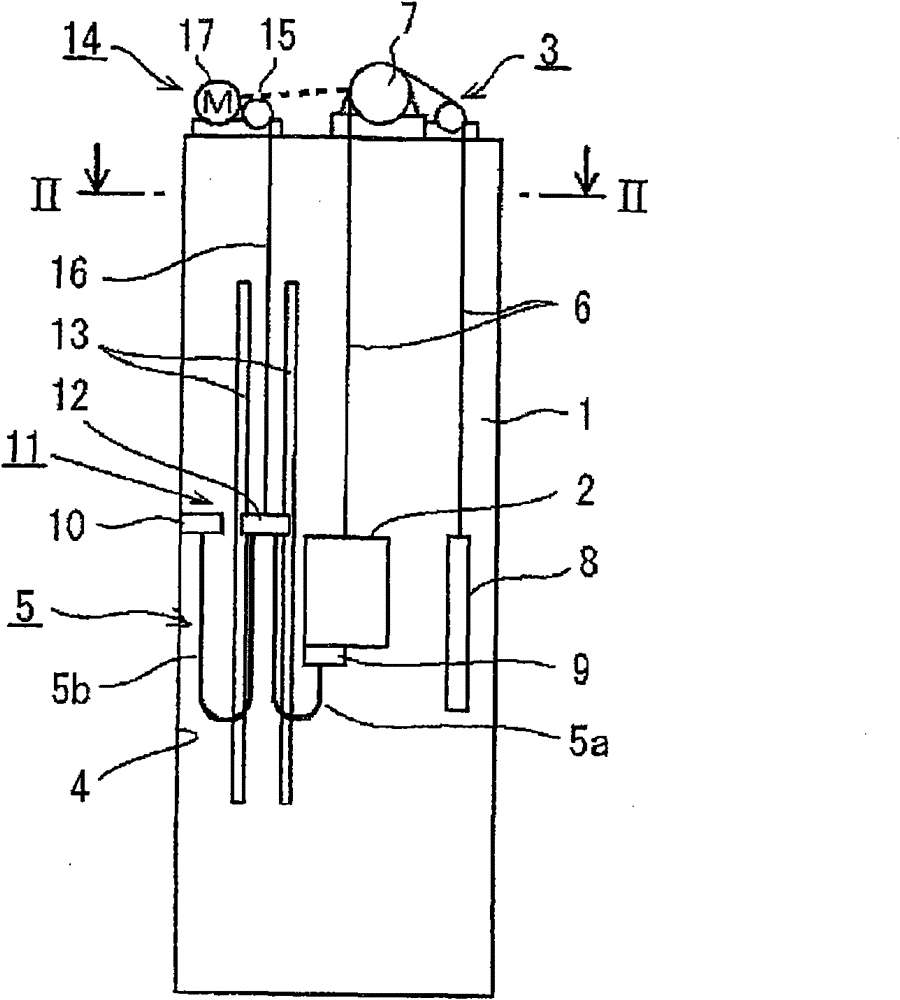

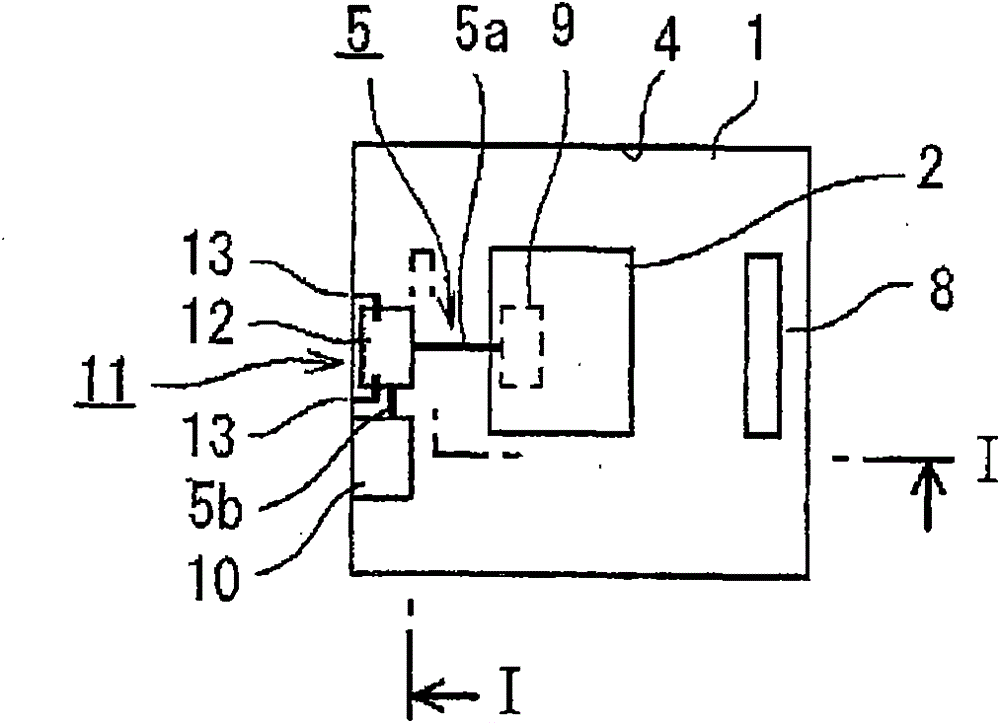

[0028] exist figure 1 Among them, the elevator of the present invention includes: a car 2, which moves along the hoistway 1; a car driving device 3, which moves the car 2; and a control cable 5, one end of which is connected to the hoistway wall 4 forming the hoistway, and the other end Connect with car 2. The car driving device 3 includes a main rope 6 connected to the car 2 and a hoist 7 around which the main rope 6 is wound, and a counterweight 8 is connected to the other end of the main rope 6 . One end of the control cable 5 is connected to the car 2 through a hanger 9 provided on the bottom wall of the car 2 . The other end of the control cable 5 is connected to a fixed hanger 10, the fixed hanger 10 is installed on the car guide rail not shown in the hoistway wall 4, and is arranged on the hoistway wall 4 for the lifting stroke of the car 2, that is, Approximate middle of the distance moved.

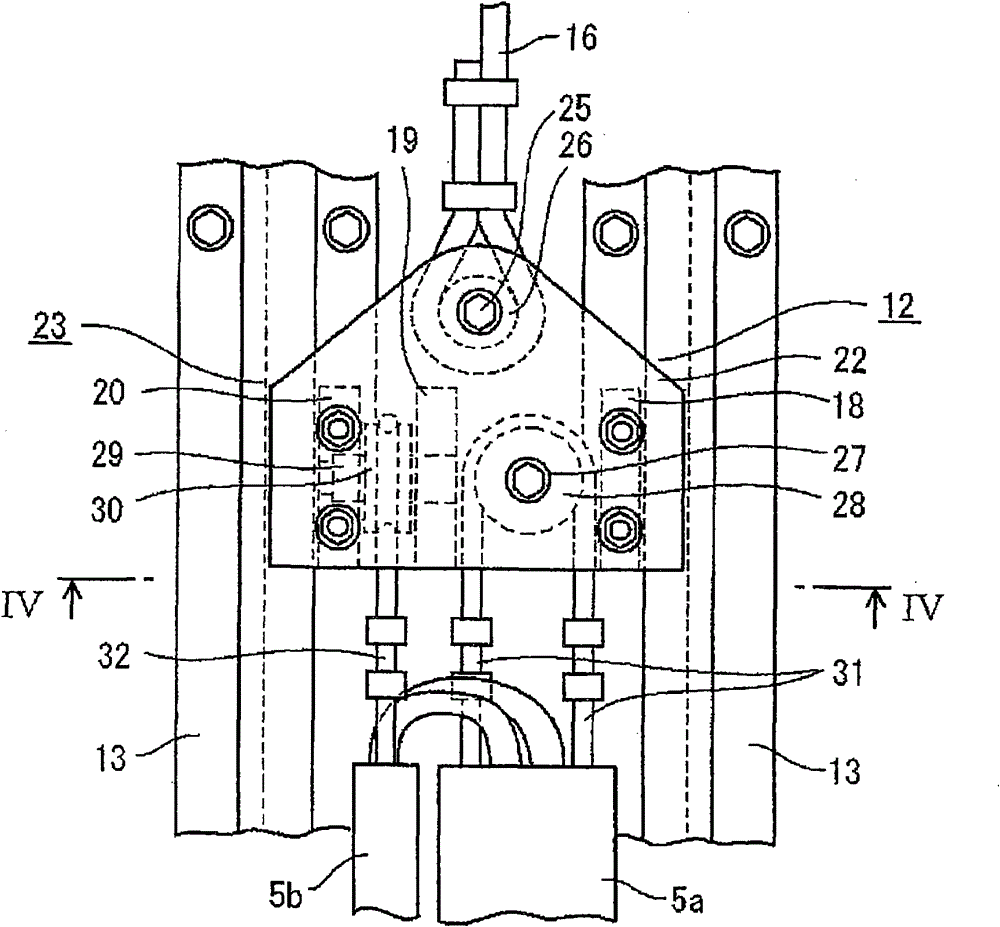

[0029] The elevator also has a mobile hanger device 11 which supports the ...

Embodiment approach 2

[0039] exist Figure 5 In the shown elevator, the traction sheave 15 of the driving device 14 of the mobile hanger device 11 is configured to be driven by the hoisting machine 7 of the car driving device 3 . In addition, the rope 16 suspended from the traction sheave 15 is connected to the movable hanger 12 in a 2:1 roping manner via a pulley 33 . That is, one end of the rope 16 is hung on the traction machine 7 of the car driving device 3, and the other end is hung on the traction sheave 15 and extends downward, and is hung on the pulley 33 installed on the movable hanger 12. Turn back upwards and connect with the floor of the machine room or the top wall 34 of the hoistway. other structures and Figure 1 ~ Figure 4 The structure shown is the same.

[0040] In this configuration, when car 2 starts from Figure 5 As shown, when the car 2 is located in the middle of the hoistway and starts to rise, the moving hanger 12 also rises in conjunction with it, but since the moving...

Embodiment approach 3

[0043] exist Figure 8 In the shown elevator, the mobile hanger device 11 has the same Figure 1 to Figure 5 In addition to the movable hanger 12 as the first movable hanger connected to the car-side cable portion 5a with the same structure as shown, there is also an intermediate movable hanger 35 as the second movable hanger. That is, the mobile hanger device 11 includes: a mobile hanger 12 connected to the car side cable portion 5a connected to one end side of the control cable 5, that is, the car 2 side; and an intermediate mobile hanger 35, which is connected to the hoistway side cable part 5b, which is connected to the other end side of the control cable 5, that is, the side of the hoistway wall 4, and the control cable 5 includes a middle cable part 5c, which will move the hanger 12 and the middle mobile hanger 35 are connected to each other.

[0044] Regarding the mobile hanger 12 as the first mobile hanger, with image 3 and Figure 4 The structure shown is the sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com